A polarization maintaining optical fiber assembly device and using method thereof

A polarization-maintaining optical fiber and assembly device technology, which is applied in the direction of optical fiber/cable installation, optics, light guide, etc., can solve the problems of inconspicuous imaging features, limited work efficiency and application range, and difficult problems, so as to facilitate docking or fusion splicing, and improve Efficiency and the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

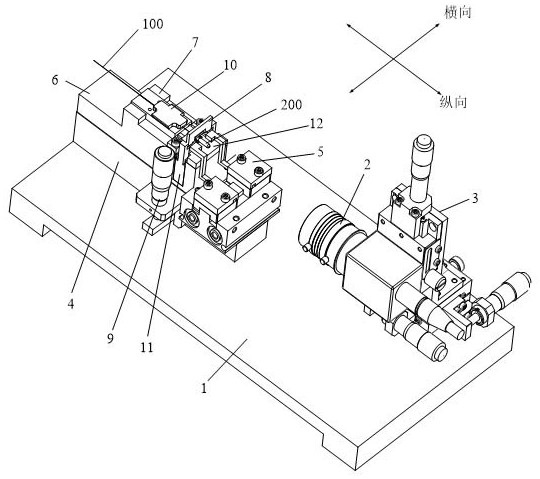

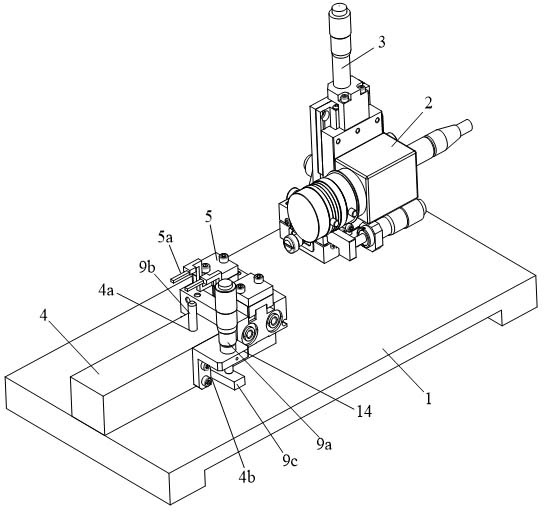

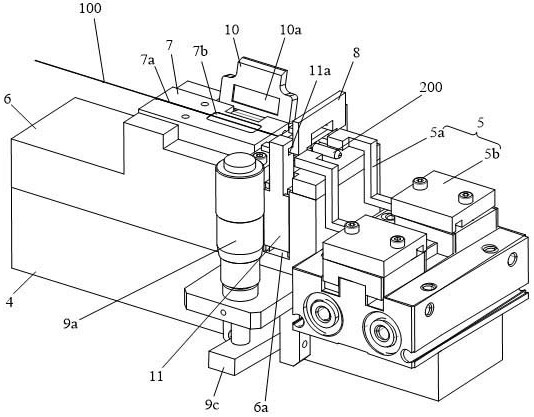

[0032] See Figure 1 to Figure 5 , The embodiment of the present invention provides a polarization maintaining optical fiber assembly device, including a stable platform 1 , an assembly jig, a turnover jig and an observation device 2 . The assembly fixture is installed on the stable platform 1, and the observation equipment 2 is installed on the adjustment frame 3. The adjustment frame 3 can adjust the position of the observation equipment 2 on the XYZ axis respectively, so that the observation equipment 2 is opposite to the end face of the ferrule 300. The observation device 2 includes a high-magnification CCD, which may be a magnifying microscope with a factor of 1,000, etc. The adjustment frame 3 is a prior art, and will not be described in detail her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com