Lithium metal negative electrode flexible protection material and preparation method thereof

A lithium metal negative electrode and protective material technology, which is applied in the direction of negative electrodes, lithium batteries, battery electrodes, etc., can solve the problems of failure to achieve commercial application, complicated processing technology of lithium metal negative electrode protective materials, and inapplicability to large-scale production and utilization. , to achieve the effect of enhancing electrical conductivity and energy storage capacity, large specific surface area, and inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 2.0g nickel acetate tetrahydrate (NiC 4 h 6 o 4 4H 2 0) be dissolved in 150mL ethanol, stirring and dissolving, obtain nickel acetate solution; After cleaning the silk with dehydrated alcohol, then soak the silk of 2.0g in the above-mentioned nickel acetate solution and stir 48h, make the silk surface adsorption one deck nickel ion, Then add 1.0g of 2,4,7-triamino-6-phenylpteridine, through coordination, the surface of nickel ion is coordinated with triphenylpterine, and the nickel ion and triphenylpteridine are loaded. silk fiber; the above-mentioned silk fiber loaded with nickel ions and triteridine was placed in a blast drying oven at 80°C for 12 hours, then pressed into a sheet-like sample, and the sheet-like sample was placed in a nitrogen atmosphere in a tube furnace Sintering at 500°C for 6h, and then cooling to room temperature to obtain a lithium metal negative electrode flexible protection material.

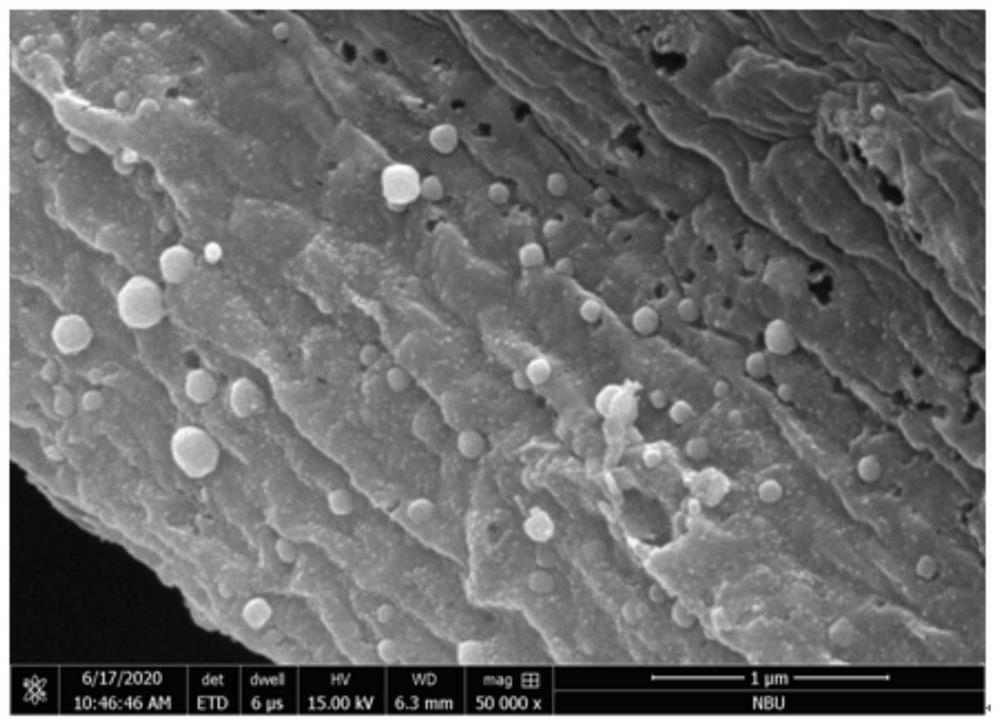

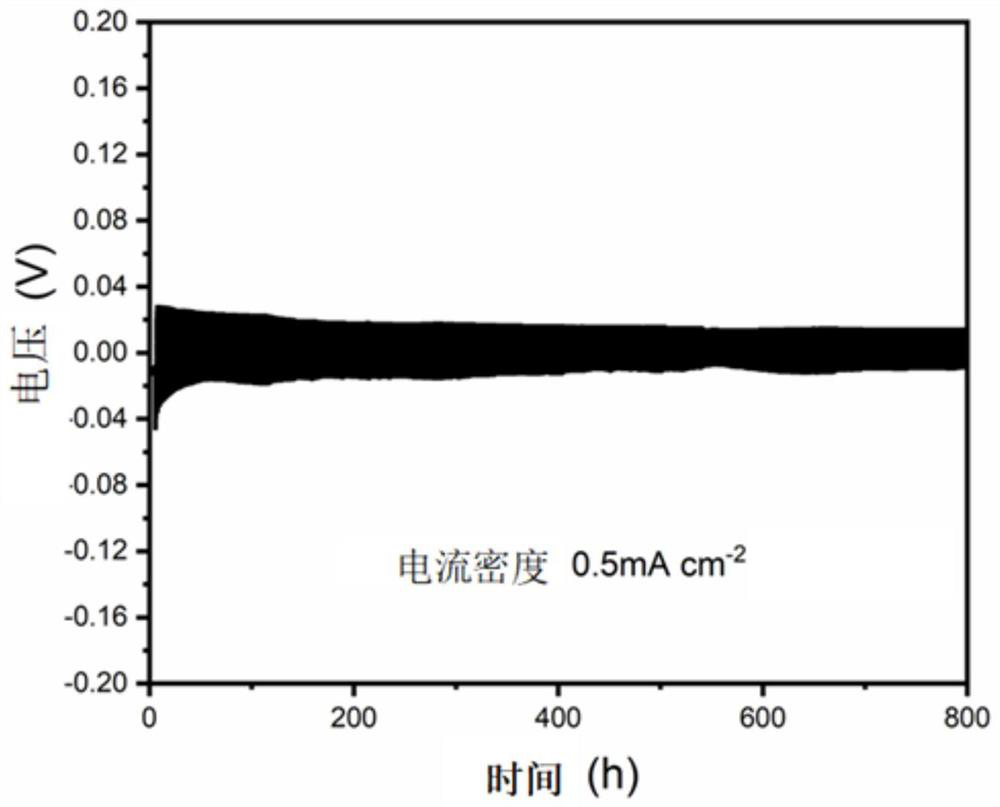

[0022] The obtained lithium metal negative electr...

Embodiment 2

[0024] Weigh 2.0g of nickel acetate tetrahydrate and dissolve it in 150mL of ethanol, stir and dissolve to obtain a nickel acetate solution; wash the silk with absolute ethanol, then soak 2.0g of silk in the above nickel acetate solution and stir for 48h to make the silk A layer of nickel ions is adsorbed on the surface, and then 1.0g of 2,4,7-triamino-6-phenylpteridine is added to coordinate the surface of nickel ions with triaminophenylpteridine to obtain nickel-loaded ions and triphenylteridine silk fibers; the above-mentioned silk fibers loaded with nickel ions and triphenylteridine were placed in a blast drying oven at 80°C for 12 hours, then pressed into a sheet-like sample, and the sheet-like sample was placed Sintering at 700°C for 4 hours in a nitrogen atmosphere in a tube furnace, and then cooling to room temperature, a flexible protective material for lithium metal negative electrodes was obtained. The obtained lithium metal negative electrode flexible protective ma...

Embodiment 3

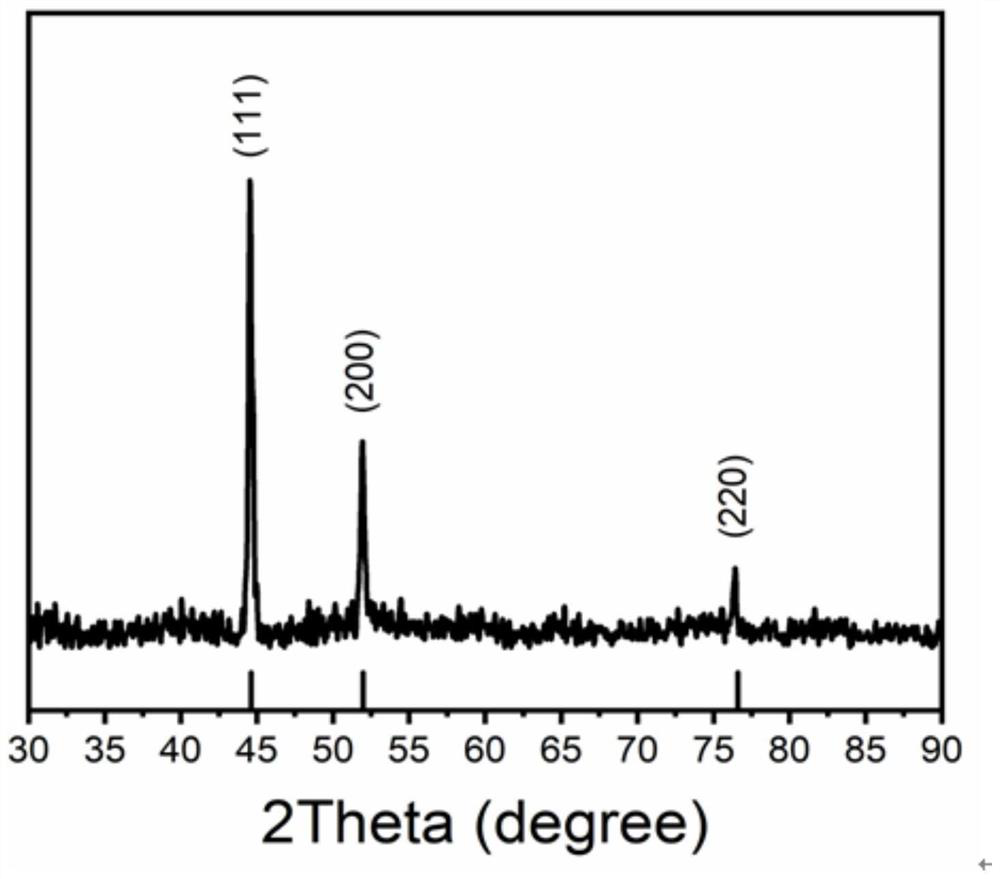

[0026]Weigh 2.0g of nickel acetate tetrahydrate and dissolve it in 150mL of ethanol, stir and dissolve to obtain a nickel acetate solution; wash the silk with absolute ethanol, then soak 2.0g of silk in the above nickel acetate solution and stir for 48h to make the silk A layer of nickel ions is adsorbed on the surface, and then 1.0g of 2,4,7-triamino-6-phenylpteridine is added to coordinate the surface of nickel ions with triaminophenylpteridine to obtain nickel-loaded ions and triphenylteridine silk fibers; the above-mentioned silk fibers loaded with nickel ions and triphenylteridine were placed in a blast drying oven at 80°C for 12 hours, then pressed into a sheet-like sample, and the sheet-like sample was placed Sintering at 600°C for 5h in a nitrogen atmosphere in a tube furnace, and then cooling to room temperature, a flexible protective material for a lithium metal negative electrode was obtained. Conduct powder X-ray diffraction analysis on the obtained lithium metal n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap