Oral planting positioner drilling device and manufacturing method

A drilling device and positioner technology, which is applied in the fields of dental drilling, dental implants, medical science, etc., can solve the problem that the dental electric drill cannot be positioned vertically, and achieve the effect of solving vertical positioning, assisting verticality, and preventing skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

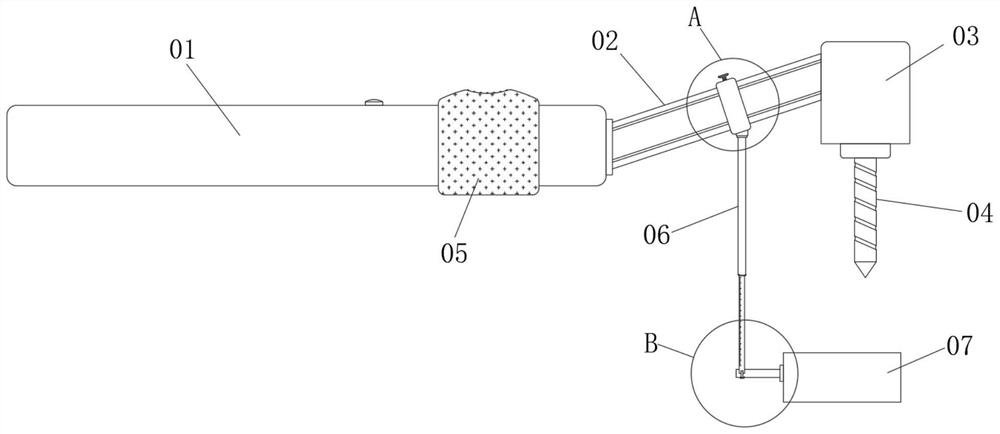

[0030] Example 1: See Figure 1-3 , a drilling device for an oral implant positioner of the present invention includes a dental electric drill body 01, the dental electric drill body 01 includes an electric drill neck 02, an electric drill driving structure 03 and a drill bit 04, and the central position of the top of the dental electric drill body 01 is set There is a switch button, the right end of the dental electric drill body 01 is provided with an electric drill neck 02, the right end of the electric drill neck 02 is provided with an electric drill driving structure 03, and a drill bit 04 is installed at the central position of the bottom of the electric drill driving structure 03, and the drill bit 04 includes a ball drill, a plurality of twist drills and tapping drills with diameters ranging from small to large. The outer surface of the electric drill neck 02 is movably sleeved with a fixed ring 09, and the central position of the bottom of the outer surface of the fixe...

Embodiment 2

[0032] Example 2: See Figure 4-5 A non-slip rubber sleeve 05 is fixedly sleeved on the outer surface of the dental electric drill body 01 close to the right side of the switch button, and a finger groove is provided at the center of the top of the anti-slip rubber sleeve 05, and the inner wall of the finger groove is evenly and fixedly connected with rubber anti-slip particles. By setting, a spring 14 is arranged between the inner cavity of the main rod of the telescopic rod 06 and the top of the sub-rod, the outer surface of the sub-rod of the telescopic rod 06 is provided with a scale line along the vertical direction, and the bottom end of the sub-rod of the telescopic rod 06 is connected to the The rod 12 is connected, and the left side of the top of the connecting rod 12 is provided with a docking groove matching the diameter of the sub-rod of the telescopic rod 06;

[0033] Through the above-mentioned structural design, it can make the doctor’s grip more stable and comf...

Embodiment 3

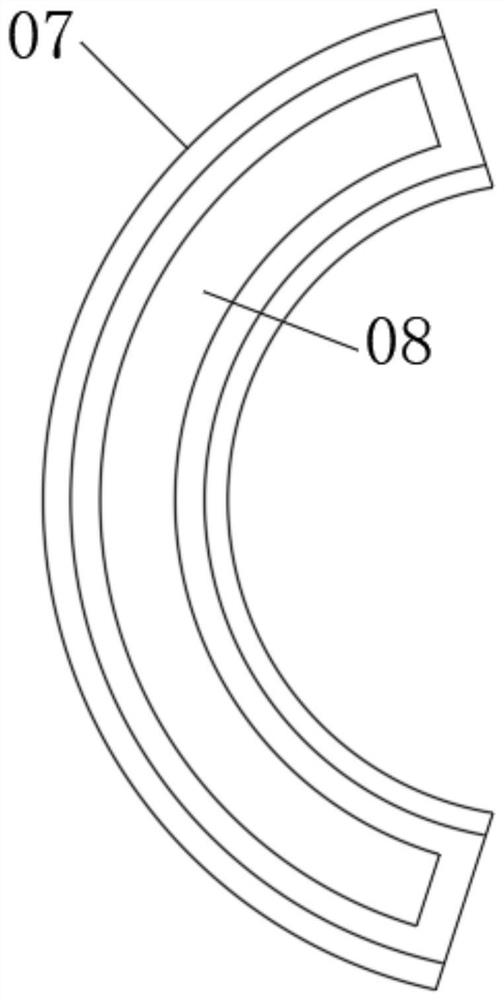

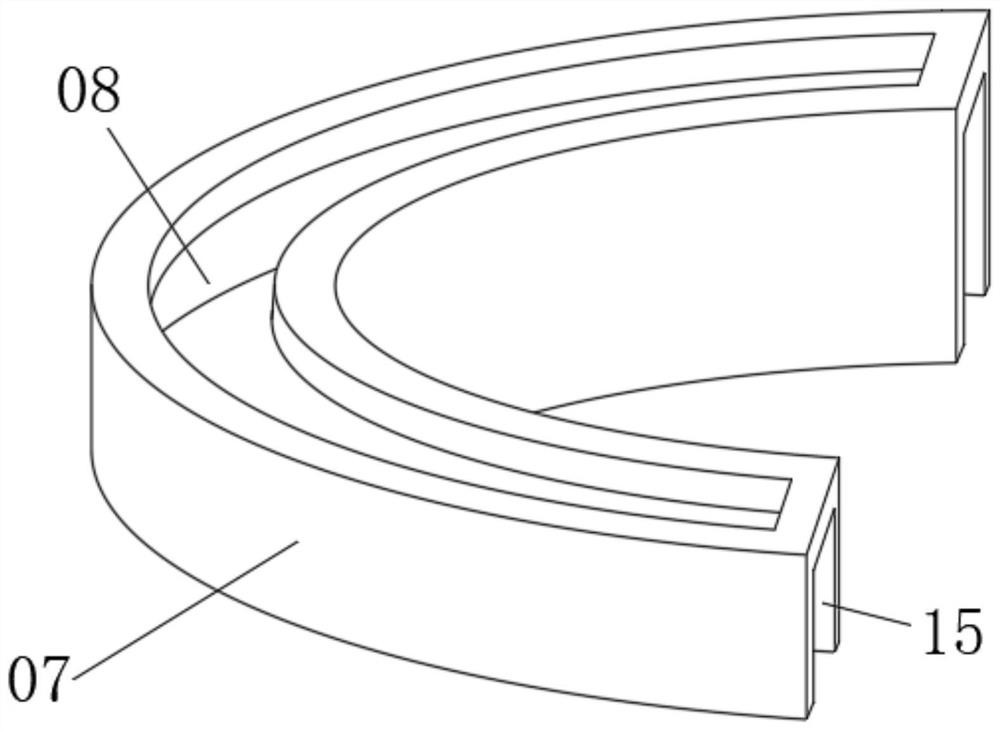

[0034] Example 3: See Figure 6-7 , the front and back of the electric drill neck 02 near the top and bottom are horizontally fixedly connected with slide rails 11, and the inner wall of the fixed ring 09 is provided with corresponding slide grooves 13 at positions corresponding to the four slide rails 11, so A fixing bolt 10 runs through the center of the top of the fixing ring 09, the top end of the fixing bolt 10 is fixedly connected with a twist handle, and the bottom end of the fixing bolt 10 is fixedly connected with a rubber block, and the top view of the positioning brace 07 is arc-shaped and is medical Made of silica gel, the size of the slot 08 is smaller than the size of the slot 15, and the slot 08 communicates with the slot 15;

[0035] Through the above structural design, the doctor can better adjust the position of the drill bit 04, and can use the fixing bolt 10 to fix the adjusted position. Use the reference point to drill vertically.

[0036] A manufacturing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com