Anchoring robot

A robot and industrial robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as difficult construction, long construction period, and high construction cost, so as to improve repair efficiency, reduce manual operation error rate, and improve grasping efficiency. Take the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

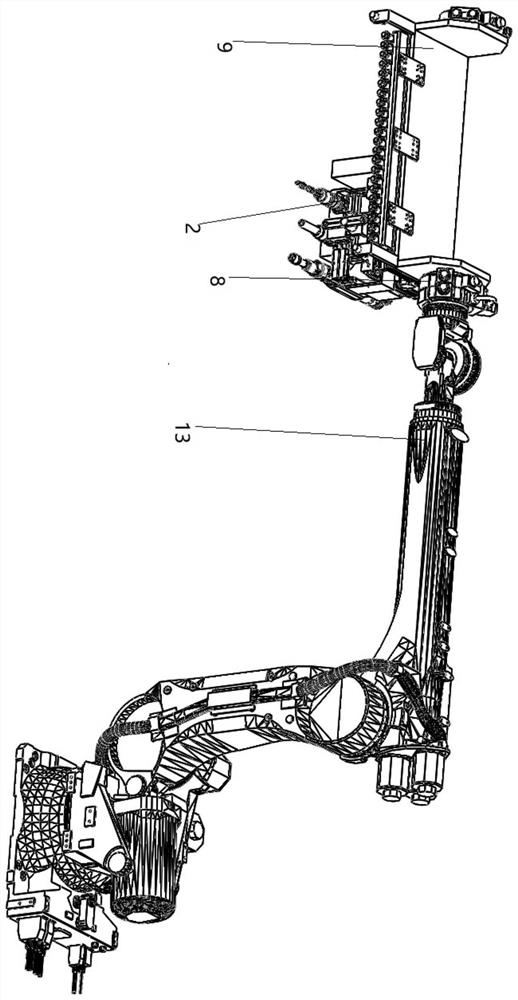

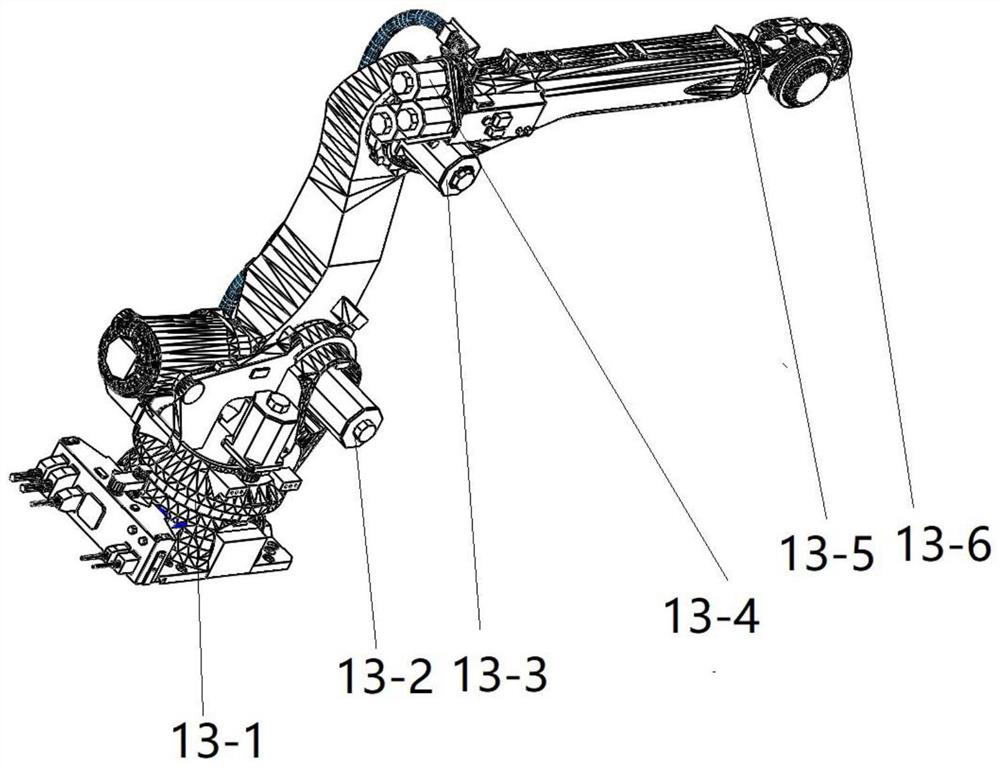

[0050] like Figure 1-2 , the present invention proposes an anchoring robot, including

[0051] A robot; the robot is a six-axis industrial robot 13;

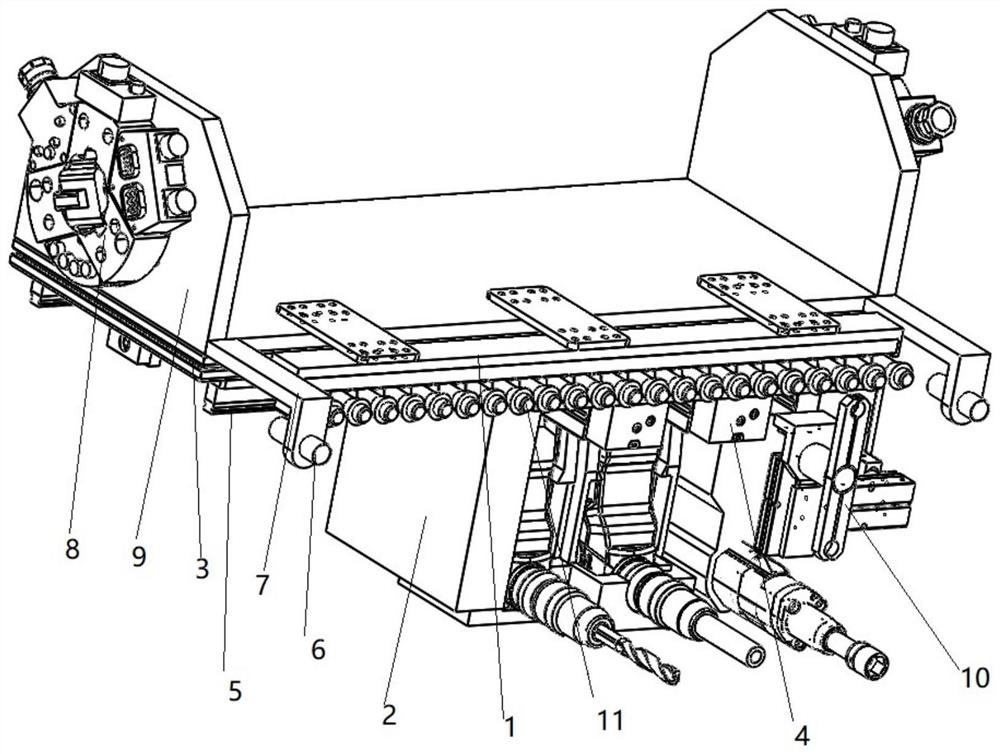

[0052] Anchor integrated component; the quick change component is set on the anchor integrated component to connect with the robot; such as image 3 - 4 anchor integrated components including:

[0053] Mounting frame 3; connecting plate 9 is arranged on the top of mounting frame 3, and the two ends of connecting plate 9 are connected with 13 hands of six-axis industrial robot;

[0054] The anchor bolt continuous feeding assembly 1; the anchor bolt continuous feeding assembly 1 is connected to the connecting plate 9 and is located on the side of the installation frame 3; the anchor bolt 11 is clamped under the anchor bolt continuous feeding assembly 1; the anchor bolt 11 is put on the A nut 12 matching it is provided;

[0055] Mobile module 2; the mobile module 2 is integrated under the installation frame 3 through the linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com