Heat sealing mechanism on medical product blister packaging machine

A technology of blister packaging and products, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high failure rate, high manufacturing cost, complex structure, etc., and achieve the effect of ensuring the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

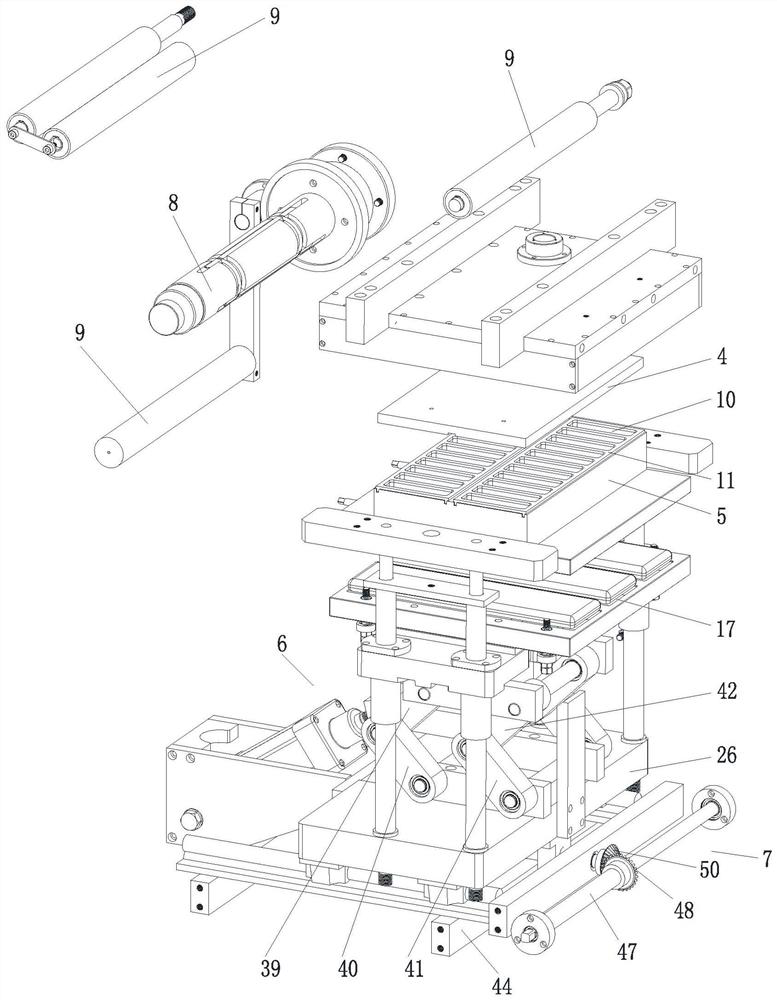

[0035] Embodiment 2: The lifting device 6 is arranged on the translation device 7, and includes a base 35, a drive cylinder 36 fixed on the base 35, and a drive block 37 connected to the stroke rod of the drive cylinder 36, and the two ends of the drive block 37 A drive shaft 38 is respectively provided, and the drive shaft 38 is hinged to the first end of the left upper rocker arm 39, the first end of the left lower rocker arm 40, the second end of the left upper rocker arm 39, and the second end of the left lower rocker arm 40. Hinged respectively on the buffer shock absorbing device 17 and the base 35, the second end of the lower right rocker 41 is also hinged on the base 35, and the first end of the lower right rocker 41 is hinged with the first end of the upper right rocker 42 , the second end of the upper right rocker arm 42 is hinged on the shock absorbing device 17, and the first ends of the upper left rocker arm 39 and the upper right rocker arm 42 are hingedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com