A kind of expansion method of underground tunnel from small section to large section

An underground tunnel, large-section technology, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of large surface settlement, difficult construction, and high risks, so as to reduce vault settlement, reduce construction risks, and save projects. The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

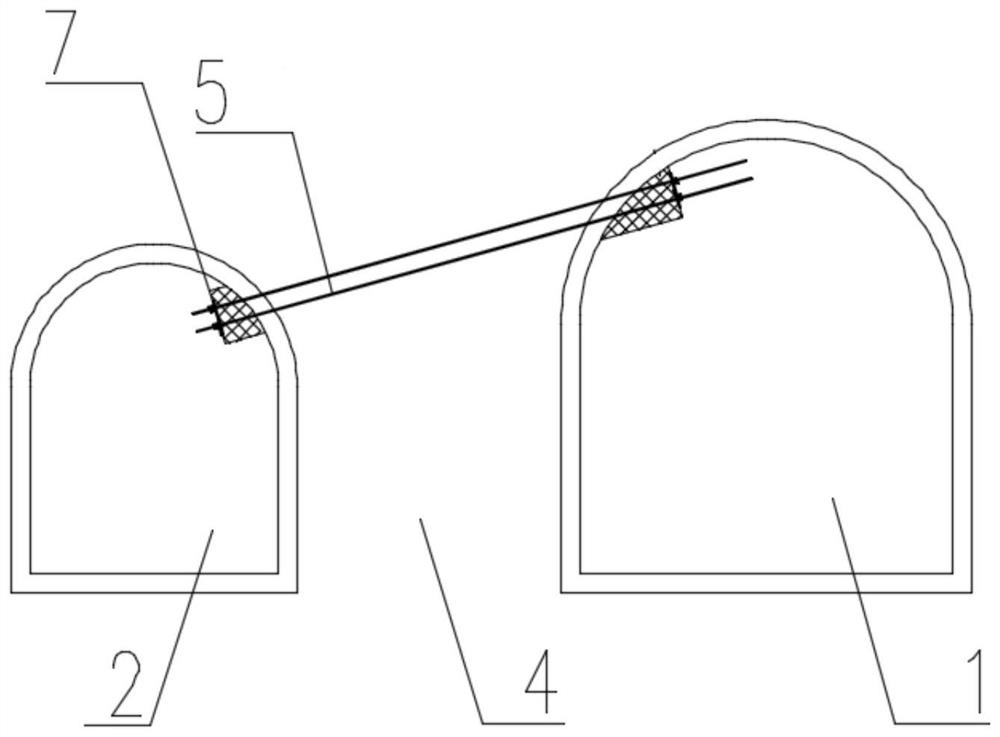

[0027] Example 1: as figure 1 As shown in the figure, a method for expanding and excavating an underground tunnel from a small section to a large section specifically includes the following construction steps:

[0028] S1, successively construct a plurality of parallel-arranged leading pilot holes required for the construction of large underground tunnels, and reserve a certain excavation spacing between adjacent leading pilot holes;

[0029] Among them, the first support of the arch part of the first pilot hole needs to be built in advance before construction, and the advance support measures should be reasonably arranged according to the characteristics of the stratum and the project;

[0030] S2, in the adjacent two leading pilot holes (such as figure 1 Between the shown first pilot hole 1 and the second pilot hole 2), at least one lateral system 5 is constructed which is connected to the primary support structure of the two pilot holes respectively. Set end anchor struct...

Embodiment 2

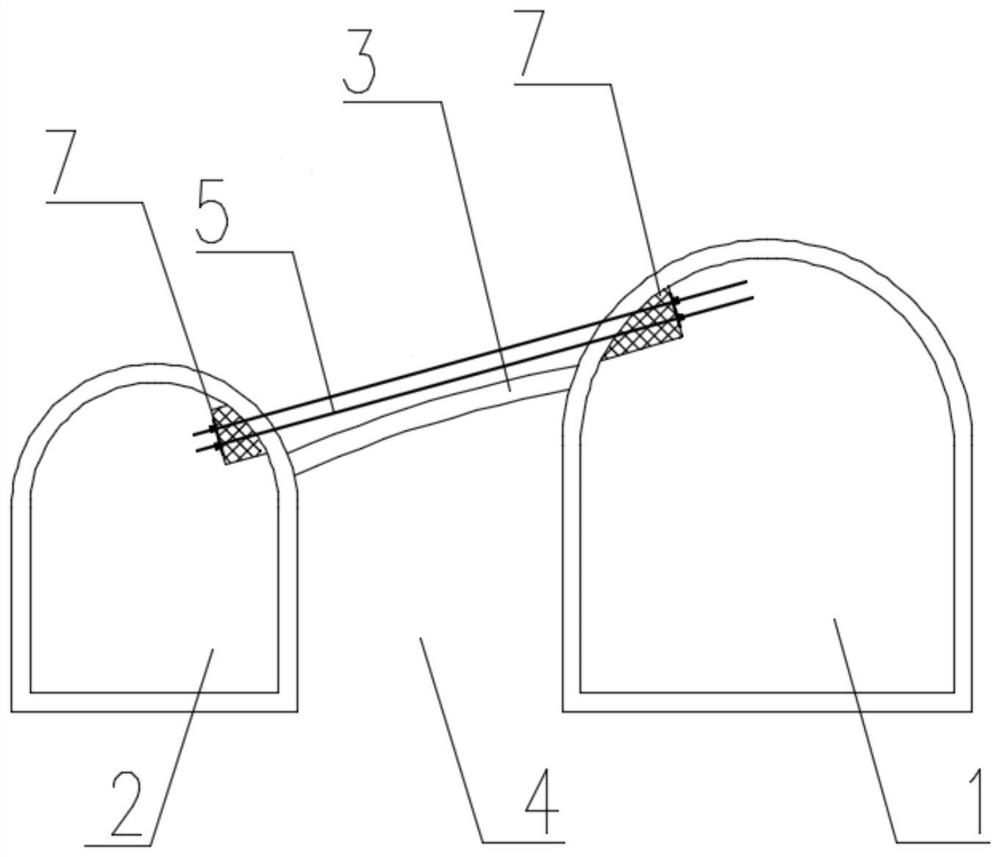

[0032] Example 2: as figure 2 As shown in the figure, a method for expanding and excavating an underground tunnel from a small section to a large section is different from Embodiment 1 in that, in step S3, two pilot holes (the first pilot hole 1 and the second pilot hole 2) are divided into two pilot holes. Before the excavation of the soil between them, the initial support structure 3 of the excavation part needs to be constructed to further ensure the safety of the excavation. Wherein, the initial support structure 3 of the excavation part is located below the lateral system 5 and is connected with the initial support structure of the two leading pilot holes.

Embodiment 3

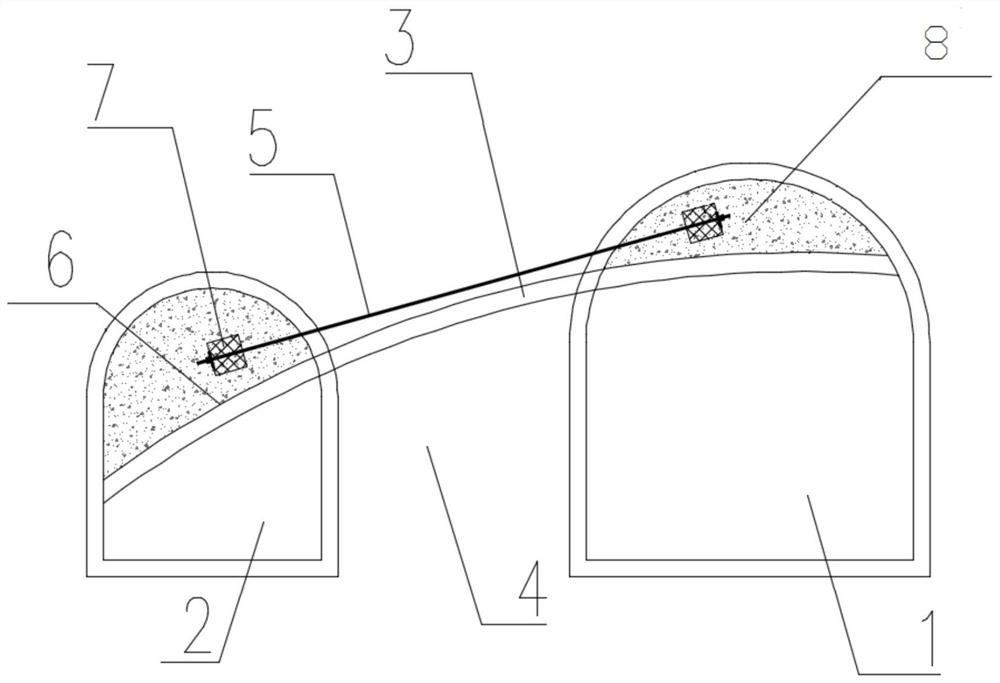

[0033] Example 3: as image 3 As shown in the figure, a method for expanding and excavating an underground tunnel from a small section to a large section specifically includes the following construction steps:

[0034] S1, successively construct a plurality of parallel-arranged leading pilot holes required for the construction of large underground tunnels, and reserve a certain excavation spacing between adjacent leading pilot holes;

[0035] Among them, the first support of the arch part of the first pilot hole needs to be built in advance before construction, and the advance support measures should be reasonably arranged according to the characteristics of the stratum and the project;

[0036] S2, in two adjacent pilot holes, such as image 3 The first pilot hole 1 and the second pilot hole 2 shown are respectively constructed in the pilot hole to expand and excavate part of the initial support structure 6 and the upper backfill layer 8, and at least one construction is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com