Layered washing method for slurry circulation system of slurry balance shield machine

A mud-water balance and shield machine technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as increased construction costs, prolonging the construction period, and affecting construction progress, and achieve savings Construction time, restoration of shield construction, effect of restoration of mud-water circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

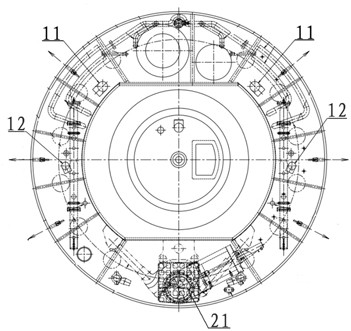

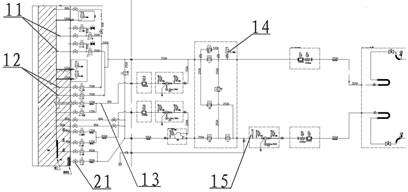

[0028] When the mud-water balance shield machine uses the internal mud-water circulation mode to flush the pipeline in the ring, the pressure sensor Ⅰ14 on the mud inlet pipe I group 11 and mud inlet pipe II group 12 shows that the pressure increases, and the mud-water circulation flow rate is 0m³ / min ;Remove the mud inlet and discharge pipelines connected to the mud tank in the ring body, and found that the mud inlet pipe group I 11 is not blocked, the mud inlet pipe group II group 12, the cutterhead center flushing pipe 13 and the main mud discharge pipe group 21 are seriously blocked; open at the same time Both the flushing pipeline and the mud discharge pipe in the center of the spare cutter head were found to be seriously blocked. According to the height of the blocked pipeline in the muddy water warehouse, it was preliminarily judged that the slag in the muddy water warehouse reached 0.5 meters above the center line. To dredge the mud tank, the steps are as follows:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com