Oil tank isolation valve fault diagnosis method and diagnosis system

A fault diagnosis system and fault diagnosis technology, applied in the charging system, adding non-fuel substances to fuel, electrical control and other directions, can solve problems such as unclear fault direction, stuck normally open fault, gas leakage and pump resistance reduction, etc. , to avoid unclear fault direction, improve accuracy, and avoid fault misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example ;

[0074] The present invention provides a fuel tank isolation valve fault diagnosis method, comprising the following steps:

[0075] S1, after forming a fault diagnosis working condition, carry out diagnostic pressure self-test;

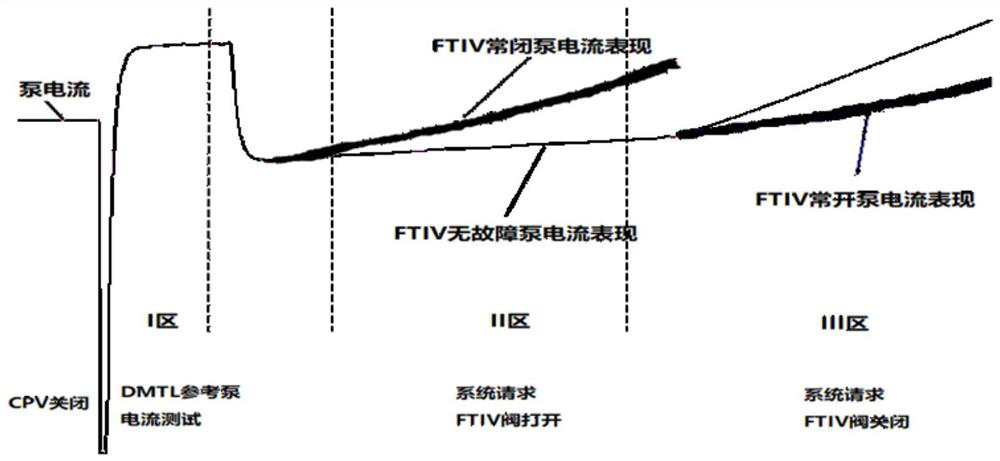

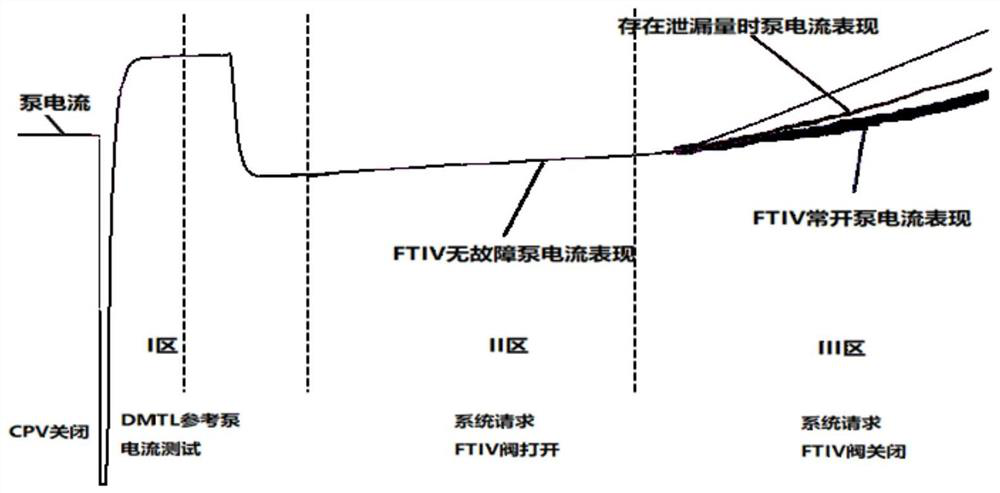

[0076] S2, pressurize the oil tank and carbon canister pipeline, and record the current variation of the diagnostic pressure source and the pressure variation of the fuel tank within the first specified period, which are recorded as ΔI1 and ΔP1 respectively;

[0077] S3, according to ΔI1 and the first specified threshold value of the current variation of the diagnostic pressure source, determine whether the fuel tank isolation valve has the first type of fault;

[0078] S4, stop pressurizing the fuel tank, continue to pressurize the carbon canister pipeline, and record the current variation of the diagnostic pressure source and the pressure variation of the fuel tank within the second specified time period, which are recorded as ΔI2 and ΔP2 respectivel...

no. 2 example ;

[0085] refer to Figure 5 As shown, the present invention provides a fuel tank isolation valve fault diagnosis method, comprising the following steps:

[0086] S1, after forming a fault diagnosis working condition, carry out diagnostic pressure self-test;

[0087] S2, pressurize the oil tank and carbon canister pipeline, and record the current variation of the diagnostic pressure source and the pressure variation of the fuel tank within the first specified period, which are recorded as ΔI1 and ΔP1 respectively;

[0088]S3, if ΔI1>a, it is determined that the fuel tank isolation valve has the first type of failure;

[0089] S4, stop pressurizing the fuel tank, continue to pressurize the canister pipeline, and record the current variation of the diagnostic pressure source and the pressure variation of the fuel tank within the second specified time period, which are recorded as ΔI2 and ΔP2 respectively;

[0090] S5, according to ΔI1 and ΔI2, determine whether the fuel tank isol...

no. 3 example ;

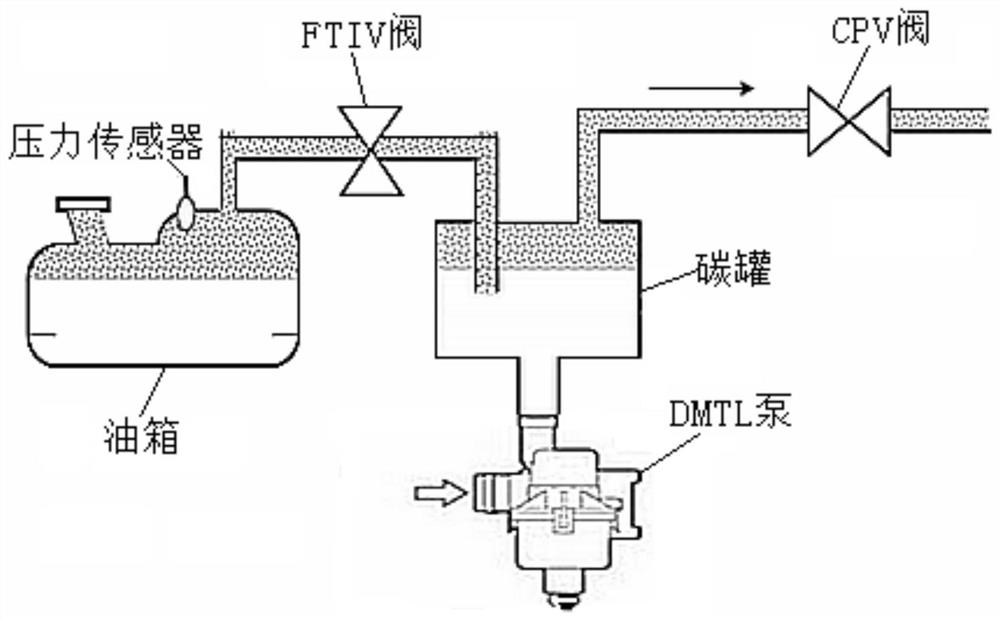

[0102] refer to figure 1 As shown, a fuel tank isolation valve fault diagnosis system includes: a pressure sensor for measuring the fuel tank pressure, which is located between the fuel tank and the carbon canister (the fuel tank isolation valve is generally integrated on the fuel tank, figure 1 The schematic diagram only shows its isolation function, so the pipeline is drawn), the fuel tank isolation valve, the diagnostic pressure source connected to the carbon tank for pressurization, the carbon tank solenoid valve located on the carbon tank pipeline, and the receiving pressure sensor and diagnostic pressure Source working parameters and control the controller (not shown in the figure) of the oil tank isolation valve, the carbon tank solenoid valve and the action of the diagnostic pressure source, the controller adopts the following steps to perform fault diagnosis; the controller can be set separately, for example, by using an MCU; or , integrating the controller with the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com