Airplane airtight cabin drain valve

A technology for airtight cabins and drain valves, which is applied to aircraft parts, lifting valves, fuselages, etc., and can solve the problems of tedious disassembly and assembly by maintenance personnel and increased manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

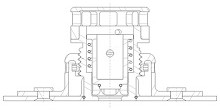

[0024] The conception, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, characteristics and effects of the aircraft airlock drain valve of the present invention.

[0025]

[0026] figure 1 It is an axial side view of an aircraft airlock drain valve in an open state in an embodiment of the present invention; figure 2 It is a three-dimensional structural schematic diagram of an aircraft airtight cabin drain valve in an embodiment of the present invention.

[0027] Such as figure 1 and figure 2 As shown, in this embodiment, the aircraft airlock drain valve 100 is installed at the fuselage drain hole 201 of the fuselage skin 200 at the bottom of the aircraft airlock cabin, for opening and closing the fuselage drain hole 201 state is controlled. The aircraft airlock drain valve 100 includes a mounting seat 10 , a valve body assembly 20 , a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com