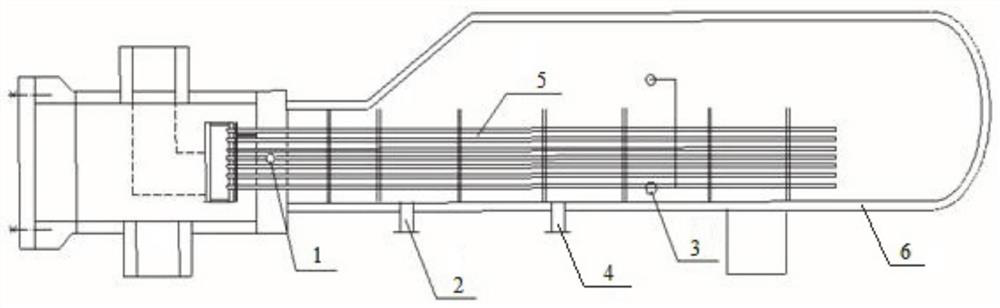

A high temperature heat exchanger and its manufacturing process

A technology of high-temperature heat exchangers and manufacturing processes, applied in the direction of indirect heat exchangers, heat exchanger types, sustainable manufacturing/processing, etc., can solve problems such as inconsistent thermal expansion coefficients, hidden dangers of equipment, weld corrosion, etc., to meet the requirements of welding Strength requirements, reduce weld lapping, and avoid salt corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

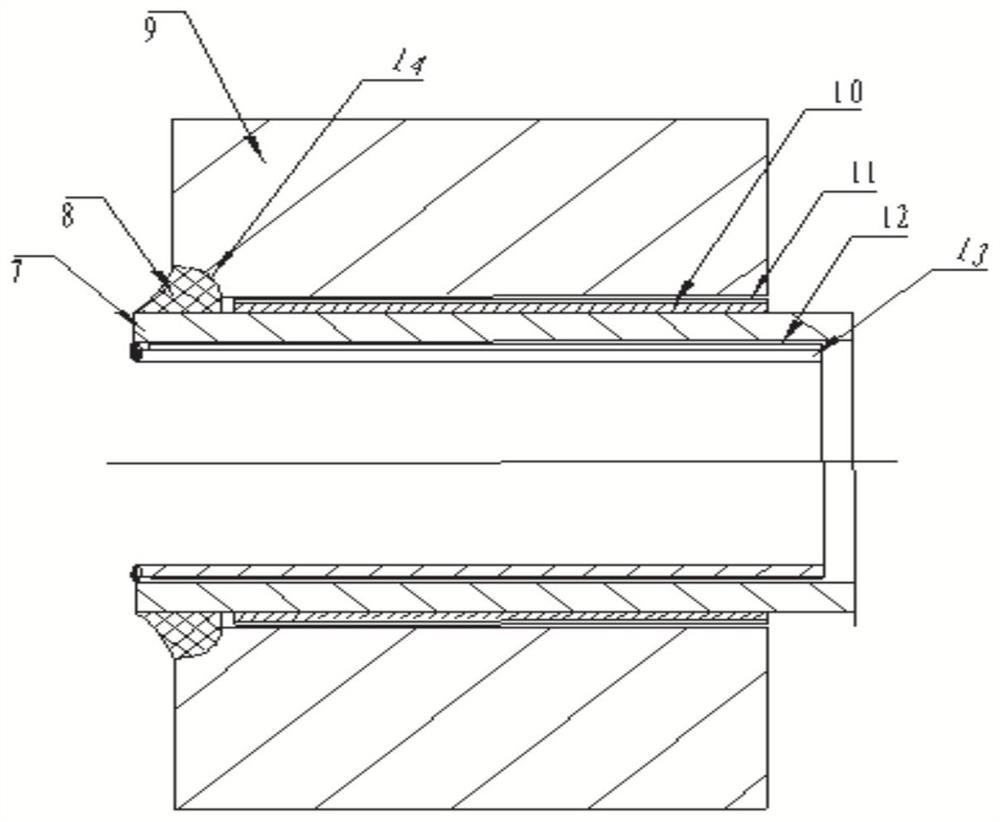

[0062] The production process of a high temperature heat exchanger with a heat exchange tube specification of Ф45×4 and a material of S32168:

[0063] (1) Polish the outer surface of the heat exchange tube in contact with the tube sheet on the heat exchange tube: use a 630 lathe, cooperate with polishing tooling to drive the thousand impeller for polishing, the polishing accuracy Ra is more than 0.8μm, and the size control after polishing is better than the outer surface of the heat exchange tube. The diameter is 0.2mm smaller;

[0064] (2) Spray high temperature anti-corrosion layer on the polished part of the heat exchange tube: spray the high temperature anti-corrosion layer on the front end of the tube sheet of the heat exchange tube, and protect the rest. The surface of the heat exchange tube should be cleaned according to the requirements of the first grade and the surface of the heat exchange tube should be cleaned; the end of the heat exchange tube is sprayed with a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com