Piezoelectric patch size measuring device and method

A technology of measuring devices and piezoelectric sheets, applied in measuring devices, optical devices, instruments, etc., can solve problems such as being vulnerable to impact or collision, bending deformation, etc., to reduce impact and collision, improve efficiency, and improve device structure Simple and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

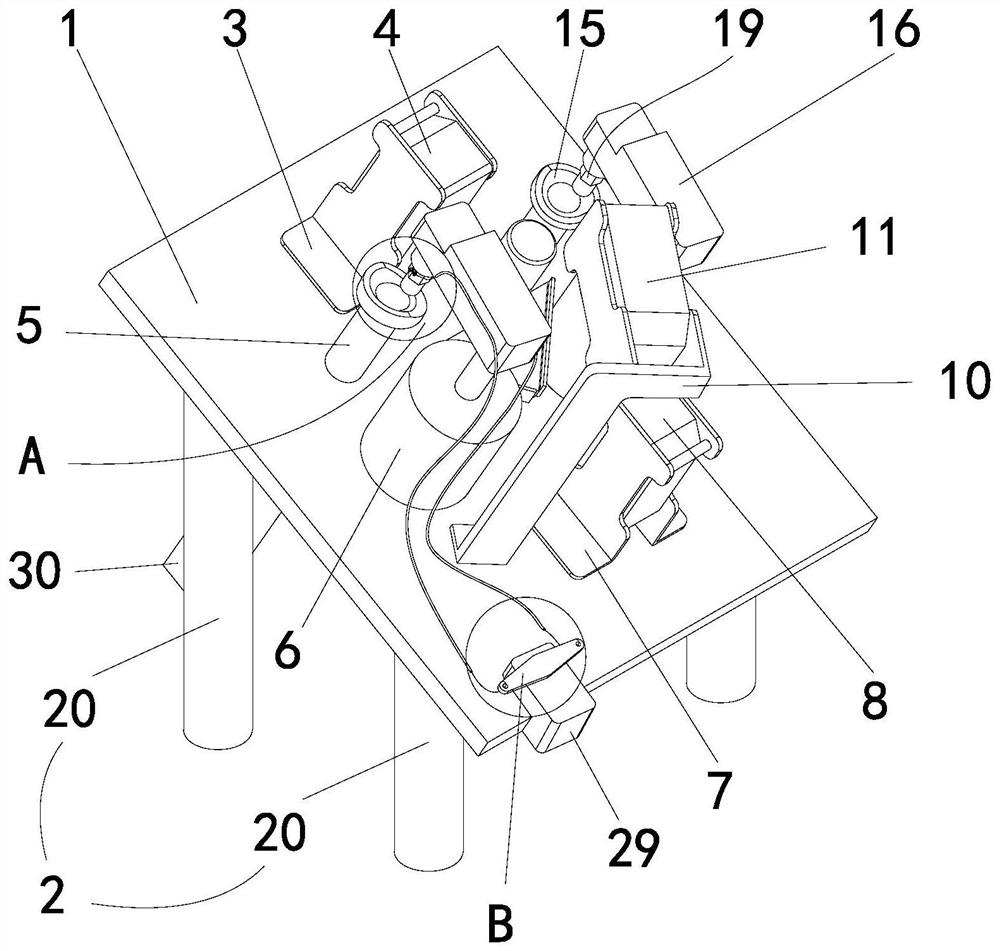

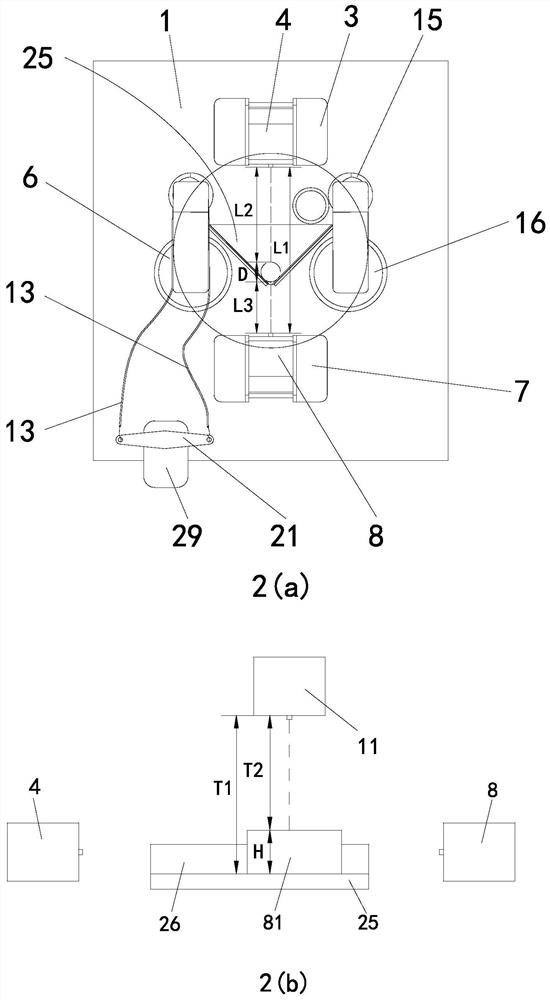

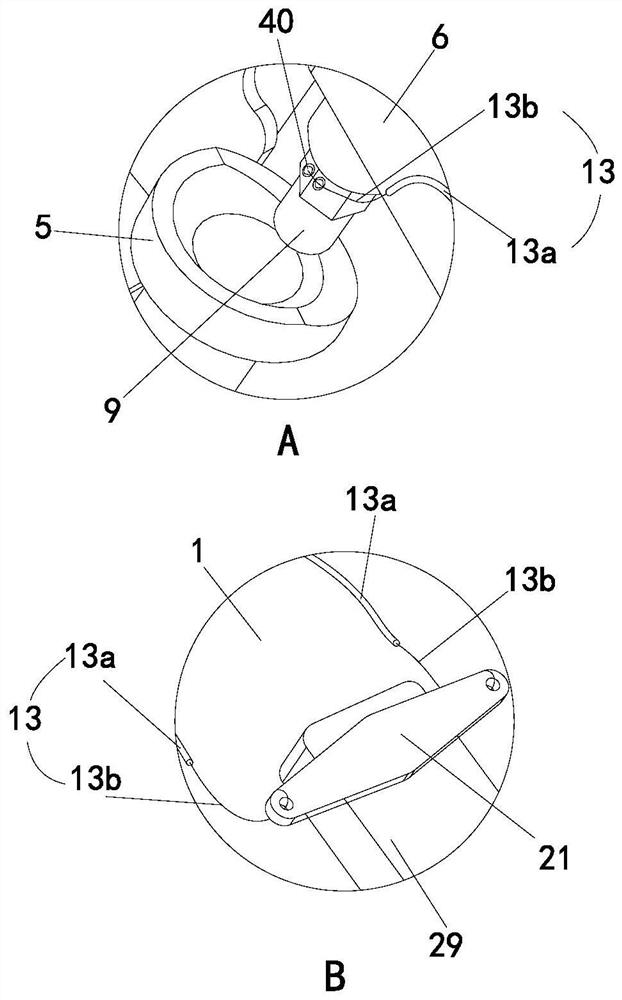

[0042] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 In the shown embodiment, a piezoelectric sheet dimension measuring device comprises a measuring platform 1, the upper end surface of the measuring platform 1 is fixedly provided with a slide test platform 25, and an angle of inclination is provided between the slide test platform 25 and the horizontal plane. The sheet testing platform 25 is set at the center of the upper end face of the measurement platform 1, and the outer edge of the end surface of the loading sheet testing table 25 is provided with a side flange portion 26 for supporting and limiting the piezoelectric sheet. The outer position is provided with a first laser displacement sensor 4 and a second laser displacement sensor 8, and the first laser displacement sensor 4 and the second laser displacement sensor 8 are arranged between the two laser displacement sensors by sho...

Embodiment 2

[0047] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 In the illustrated embodiment, a method for measuring the size of a piezoelectric sheet includes the following measurement execution steps:

[0048] A1. The first mechanical arm 6 in the feeding mechanism absorbs and takes out the piezoelectric sheet 81 located on the uppermost layer in the feeding cylinder 5;

[0049] A2. The first mechanical arm 6 in the feeding mechanism drives the first suction nozzle 9 and the piezoelectric sheet 81 adsorbed and taken out in the above-mentioned step A1 to move to the position where the slide test table 25 is located in a manner of rotating and moving downward. ;

[0050] A3. When the piezoelectric sheet 81 is located near the target position on the slide test platform 25, the first suction nozzle 9 stops sucking air, and the piezoelectric sheet 81 falls downward into the slide test platform 25;...

Embodiment 2

[0072] figure 1 An embodiment of the measuring platform 1 is shown, the measuring platform 1 and the horizontal plane are provided with an inclination angle of the same inclination angle size between the slide test platform 25 and the horizontal plane, the tilting measuring platform 1 is passed, and the tilting measuring platform 1 is kept The parallel state between the end face and the end face of the slide test bench 25 makes the adjustment of the inclination of the slide test bench 25 end face completed by adjusting the inclination of the tilt measurement platform 1; the first laser displacement sensor 4 and the second laser displacement Sensor 8 and the third laser displacement sensor 11 are fixed on the test platform 1, and the connection line between the first laser displacement sensor 4 and the second laser displacement sensor 8 is kept parallel to the end face of the slide test bench 25, and the third The laser emitting end face of the laser displacement sensor 11 is k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com