Solar cell module and preparation method thereof

A solar cell and module technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as uneven stress, overheating of solar panels, temperature burnout, etc., to improve heat conduction efficiency, improve power generation efficiency, and prevent cracks damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

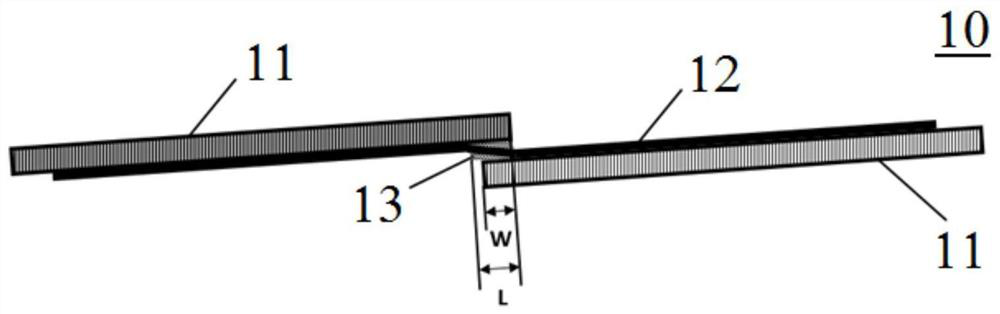

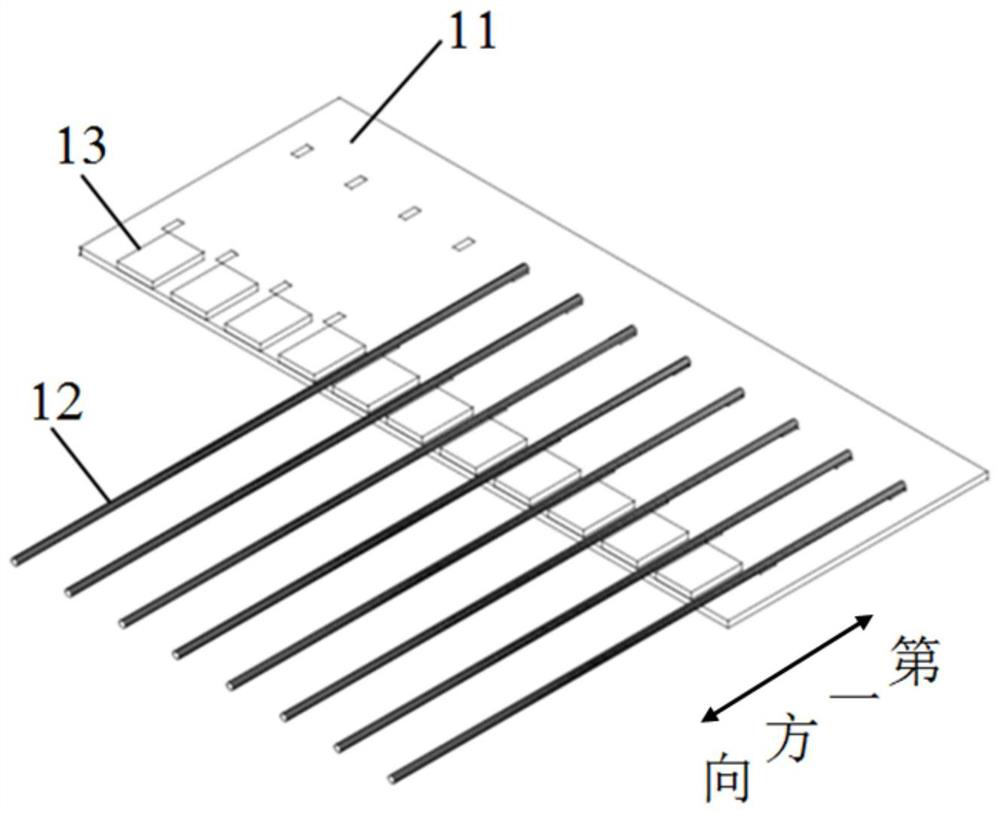

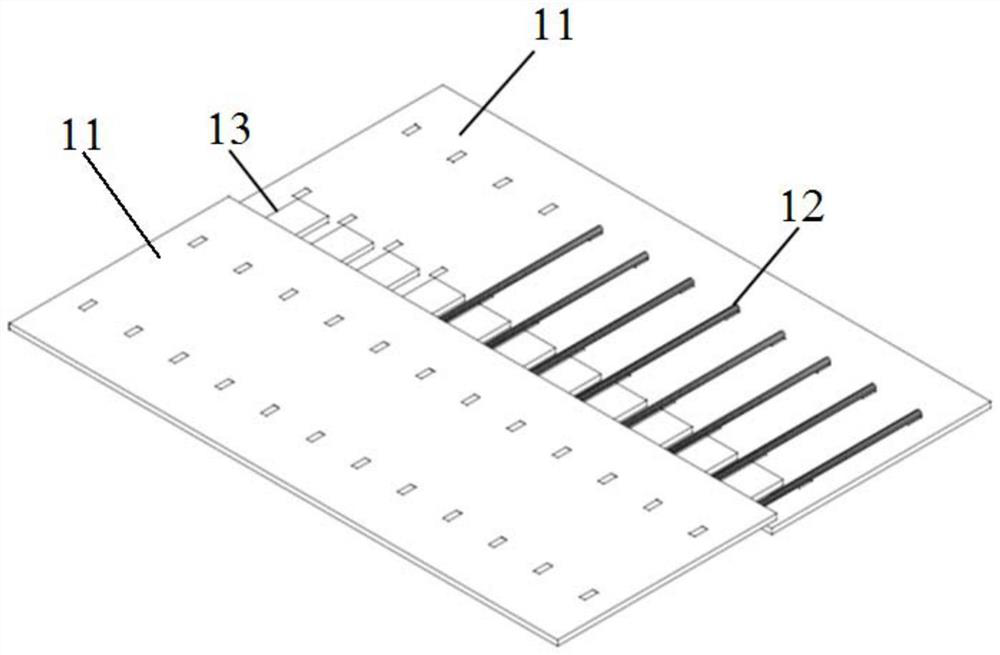

[0038] Such as figure 1 as shown, figure 1 It is a schematic diagram of a battery string of a solar battery module according to an embodiment of the present invention, the solar battery module includes a plurality of battery strings 10, wherein:

[0039] Each battery string 10 includes a plurality of battery slices 11 connected in series, a conductive structure 12 disposed between every two adjacent battery slices 11 , and a supporting heat transfer block 13 .

[0040] In every two adjacent battery slices 11 of the battery string 10, there is an overlapping area between the back of the first battery slice and the front of the second battery slice; the light-receiving surface of the battery slice is the front of the battery slice, and the backlight surface of the battery slice is the battery slice in the back. Wherein, any battery piece 11 in the battery string 10 can be used as the first battery piece, and the battery piece 11 that is adjacent to the first battery piece and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com