Plasma degumming method for mixed-pressed circuit board

A circuit board and plasma technology, applied in printed circuit, printed circuit manufacturing, printed circuit secondary treatment, etc., can solve the problem that the degumming parameters cannot match the desmearing effect of two materials at the same time, and the degumming parameter range is narrow , Excessive degumming of easy-to-remove materials, etc., to achieve good metallization effects, avoid quality abnormalities, and good degumming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In view of the defects in the above-mentioned existing mixed-pressure circuit board deglue process, the applicant actively researches and innovates based on his rich practical experience and professional knowledge in the design and manufacture of such products for many years, and cooperates with the application of academic theories, in the hope of creating The technology capable of solving the defects in the prior art makes the deglue process of the mixed-pressure circuit board more practical. Through continuous research, design, and after repeated trial samples and improvements, the present invention with practical value is finally created.

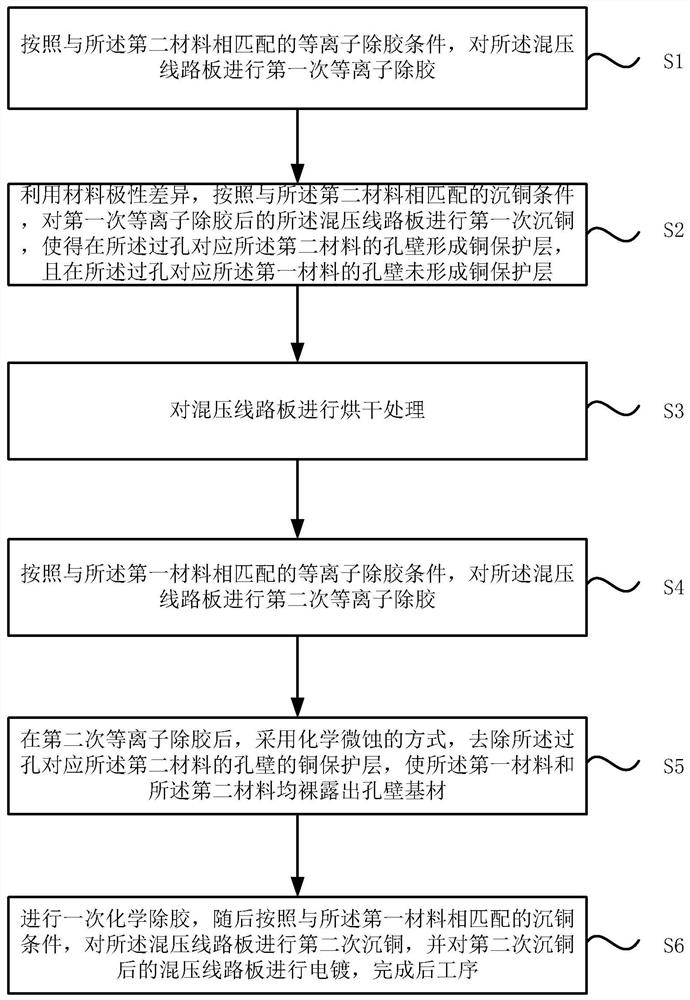

[0032] Please refer to figure 1 , an embodiment of the present invention provides a plasma deglue method for a mixed-pressed circuit board, the mixed-pressed circuit board is made of mixed-pressed first material and second material, and the mixed-pressed circuit board is processed with the first material and the non-metallized vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com