Automatic grafting equipment for greenhouse seedling-raising jujube trees

An automatic grafting and jujube tree technology, applied in grafting and other directions, can solve problems such as damage to rootstock joints, high labor costs, bark cracking, etc., to achieve the effects of reducing resistance, improving joint effect, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

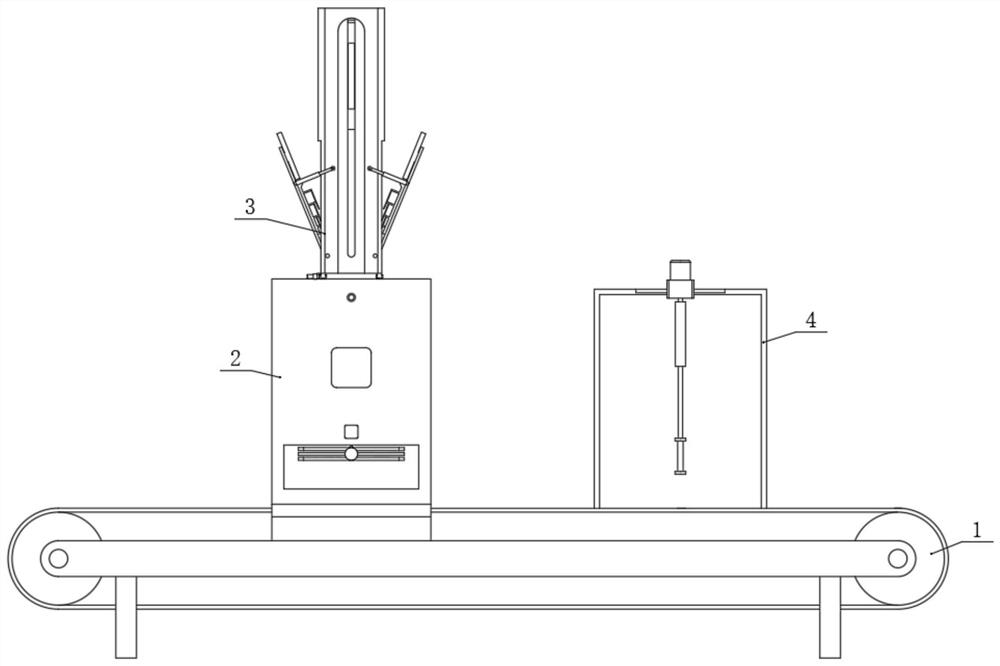

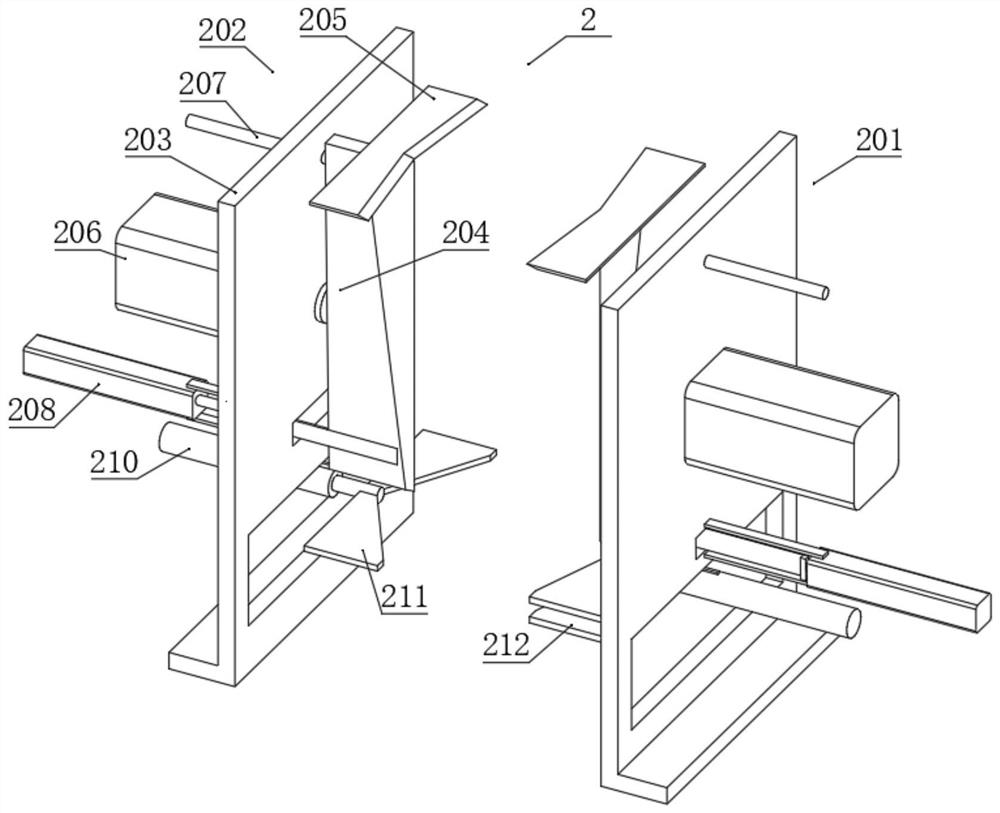

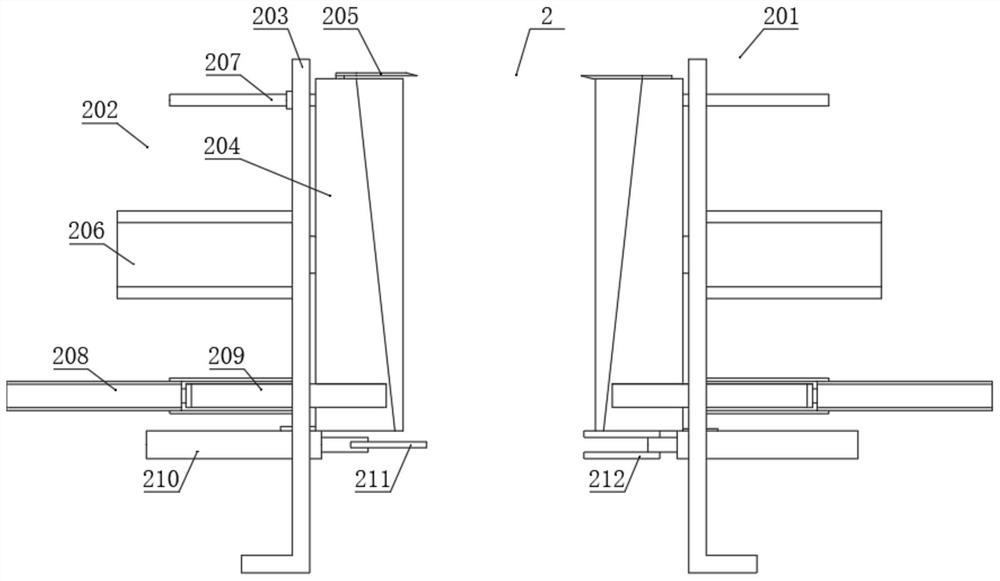

[0029] see figure 1 , jujube tree automatic grafting equipment for greenhouse seedlings, comprising a conveyor belt 1, the top of the conveyor belt 1 is sequentially provided with a rootstock cutting mechanism 2 and a coating mechanism 4 along its conveying direction, and the top of the rootstock cutting mechanism 2 is provided with a scion cutting mechanism. Mechanism 3; the rootstock cutting mechanism 2 cuts off the jujube seedlings to become a rootstock, and the rootstock cutting mechanism 2 splits the rootstock from both sides inwardly and spreads the rootstock; the scion cutting mechanism 3 pairs the scion Both sides of the end are cut and the cut scion is inserted into the gap where the rootstock is split. By setting the rootstock cutting and splitting mechanism 2, jujube seedlings can be cut off automatically to form a rootstock and the rootstock can be split. Cooperate with the scion cutting mechanism 3 , can automatically insert the cut scion into the gap of the roots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com