High-precision controllable plate-type ultra-wide copper strip used for transformer and production technology of high-precision controllable plate-type ultra-wide copper strip used for transformer

A preparation process and high-precision technology, which is applied in the direction of manufacturing tools, roll speed control, rolling force/roll gap control, etc., can solve the problem of poor performance of copper strips, and achieve strict, reliable, accurate and high-precision inspection processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

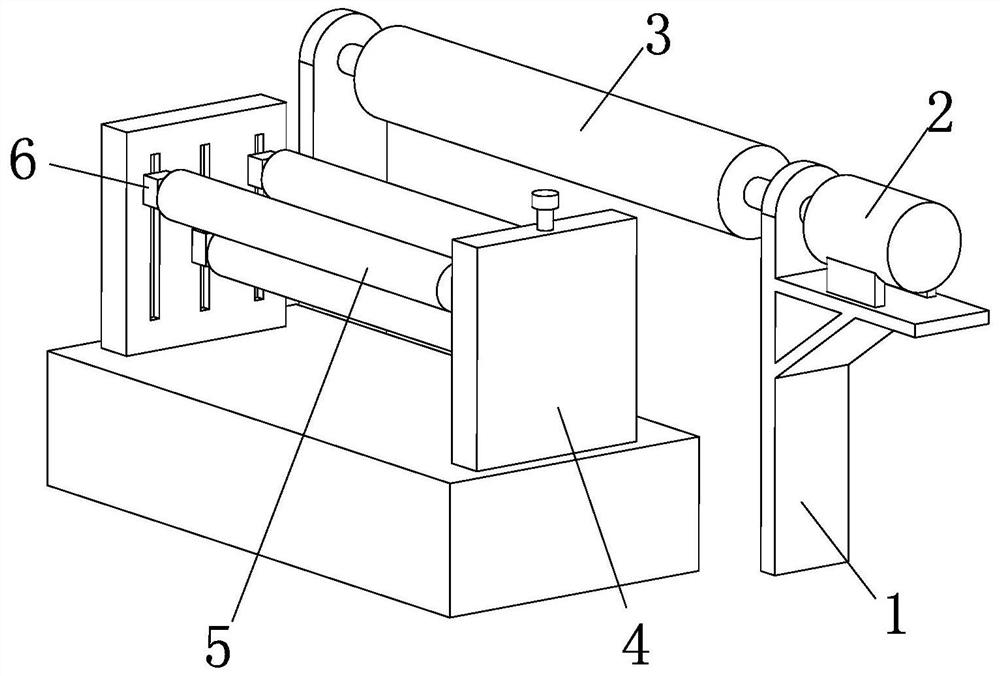

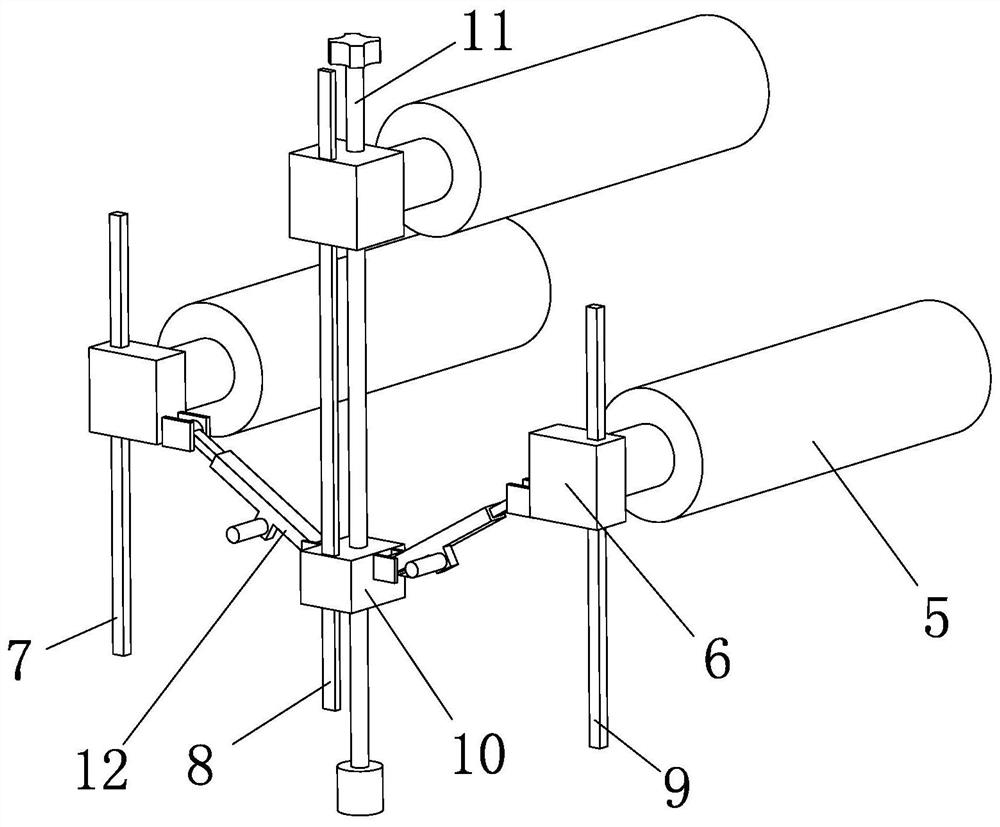

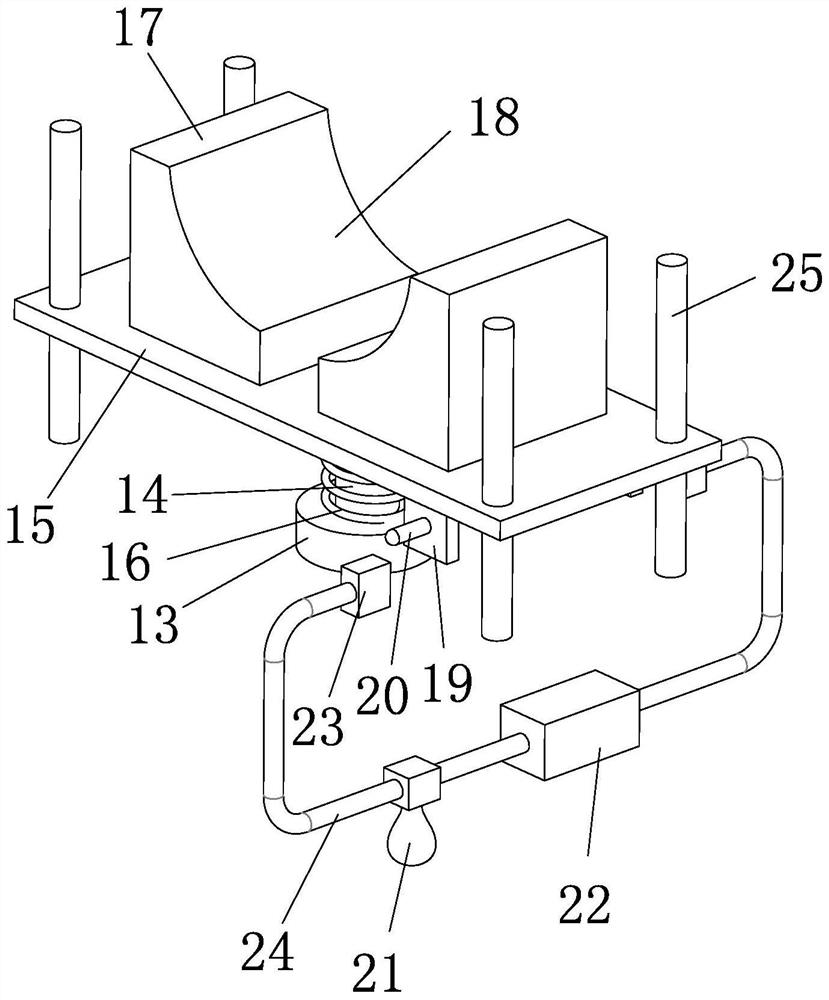

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0034] A process for preparing an ultra-wide copper strip with high precision and controllable shape for transformers, characterized in that it includes the following steps:

[0035] Step 1: Put the copper block raw material into the copper melting tower to dissolve to obtain copper liquid, and then pour the copper liquid into the mold to form an ingot;

[0036] Step 2: melting and drawing the copper block;

[0037] Step 3: Put the copper block into the walking furnace to heat, and after heating, carry out hot rolling to open the embryo to obtain the rough material;

[0038] Step 4: put the rough material into the rough rolling mill for rough rolling;

[0039] Step 5: Put the coarse material that has been rough rolled in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com