An assembly and method suitable for batch electron beam welding of sputter rings

An electron beam welding and vacuum electron beam welding technology, which is applied in the field of magnetron sputtering, can solve the problems of low efficiency of vacuum electron beam welding, etc., and achieves the advantages of saving multiple vacuuming and cooling time, convenient and flexible combination, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

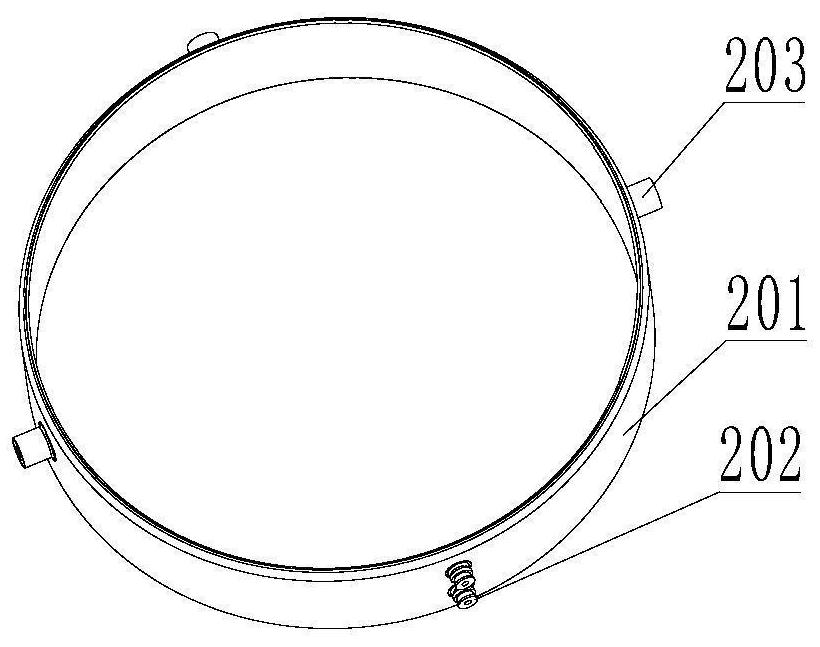

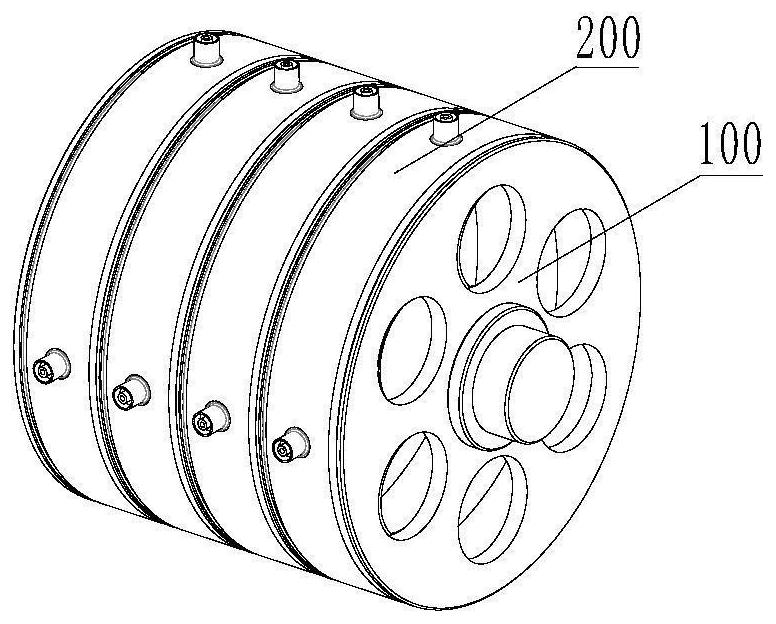

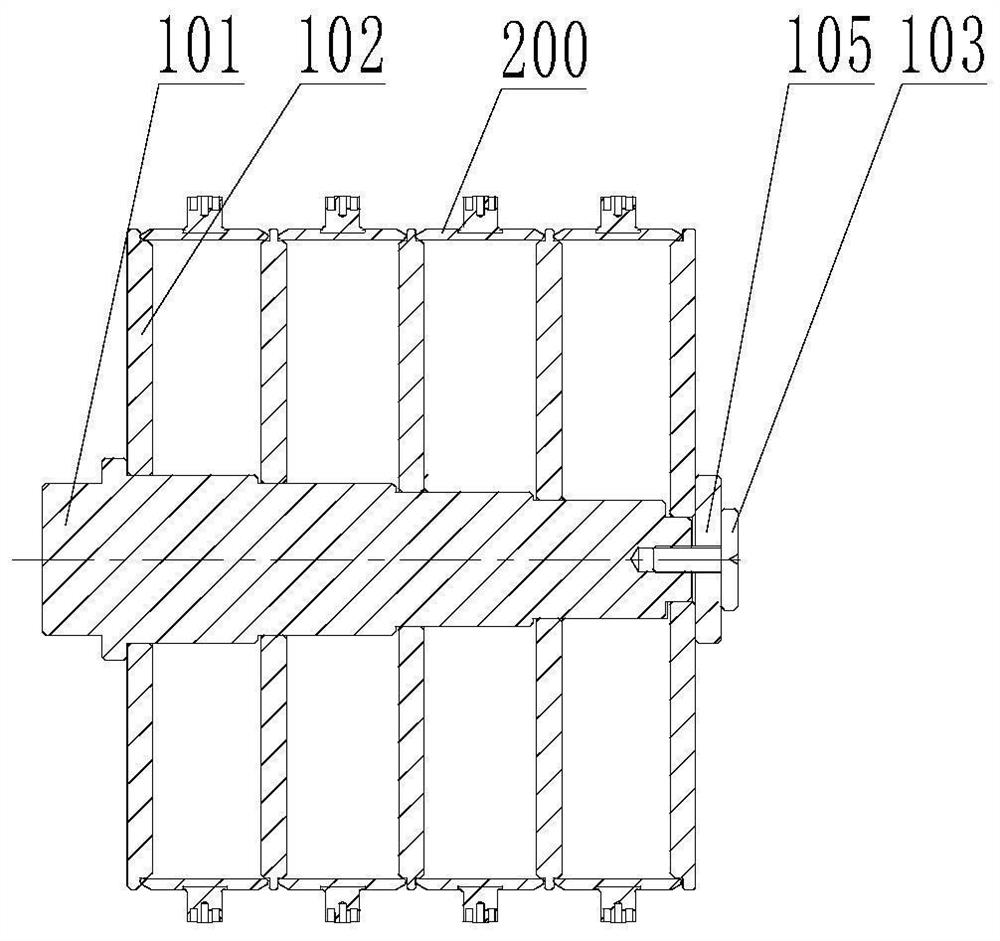

[0030] like image 3 Shown is a schematic diagram of the assembly when welding four sputter rings. After the mandrel 101 is fixed on the chuck of the vacuum electron beam welder and adjusted, a separator 102 is first installed on the mandrel 101, and then the sputtering ring 200 and the separator 102 are installed in sequence, and a total of 4 sputterings are installed Ring 200, separator 102, and finally install the baffle 105 behind the last separator, adjust the relative positions of the supports 203 and electrodes 202 of the four sputtering rings 200 so that the supports 203 of the four sputtering rings 200 are parallel to each other. On the same line of the centerline of the mandrel, the electrodes 202 of the four sputtering rings 200 are located on the same line parallel to the centerline of the mandrel, tighten the bolts 103, and push the top of the vacuum electron beam welding machine table to the bolts 103. , so that the sputter ring batch welding assembly is install...

Embodiment 2

[0032] like Figure 4 Shown is a schematic diagram of the assembly when welding three sputtering rings. After the mandrel 101 is fixed on the vacuum electron beam welding machine chuck and adjusted, a separator 102 is first installed on the mandrel 101, and then the sputtering rings are installed in sequence. The ring 200 and the separator 102 are installed three times in total, and the relative positions of the supports 203 and the electrodes 202 of the three sputter rings 200 are adjusted so that the supports 203 of the three sputter rings 200 are parallel to each other. The electrodes 202 of the three sputtering rings 200 are located on the same line parallel to the centerline of the mandrel, and the first sleeve 104 is placed on the mandrel 101, and finally the baffle 105 is placed on the mandrel 101. After being installed on the first sleeve 104, the bolts 103 are tightened, and the top of the vacuum electron beam welding machine table is pushed onto the bolts 103, so tha...

Embodiment 3

[0034] like Figure 5 Shown is a schematic diagram of the assembly when welding two sputtering rings. After the mandrel 101 is fixed on the vacuum electron beam welding machine chuck and adjusted, a separator 102 is first installed on the mandrel 101, and then the sputtering rings are installed in sequence. The ring 200 and the separator 102 are installed three times in total, and the relative positions of the supports 203 and the electrodes 202 of the two sputter rings 200 are adjusted so that the supports 203 of the two sputter rings 200 are parallel to each other. The electrodes 202 of the two sputtering rings 200 are located on the same line parallel to the centerline of the mandrel, and the second sleeve 106 is placed on the mandrel 101, and finally the baffle 105 After being installed on the second sleeve 106, the bolts 103 are tightened, and the top of the vacuum electron beam welding machine table is pushed onto the bolts 103, so that the sputter ring ring batch weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com