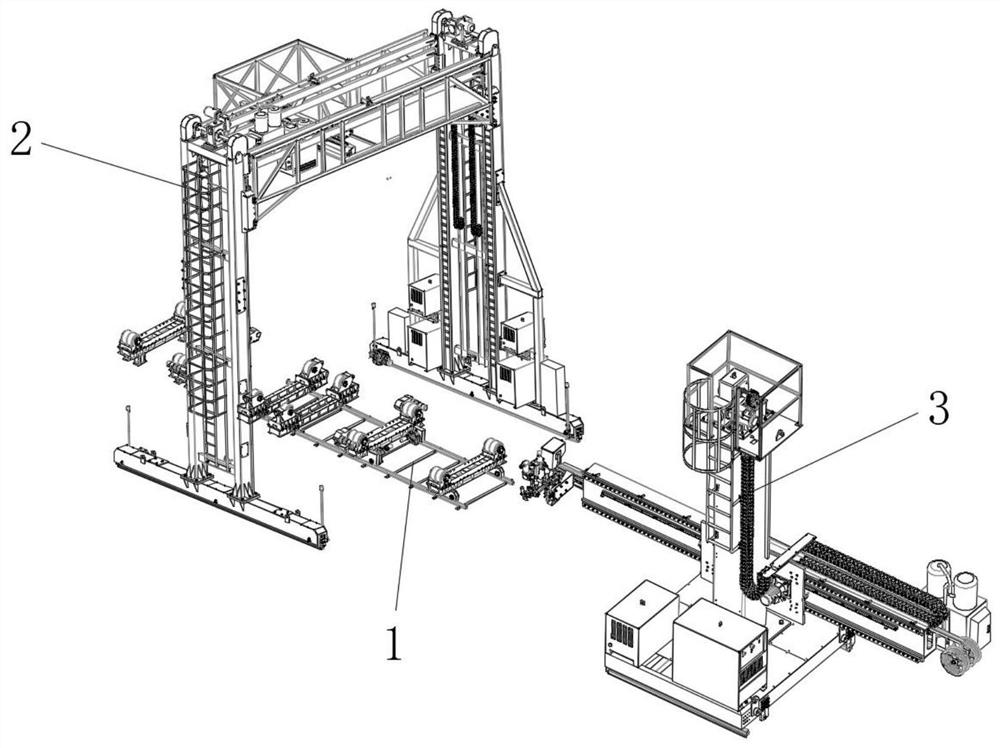

Large pipeline welding system

A welding system and pipeline technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of easy vibration of welding equipment, low work efficiency, and inability to guarantee the quality of welding seams, etc., and achieve good welding effect, Optimizing the results of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

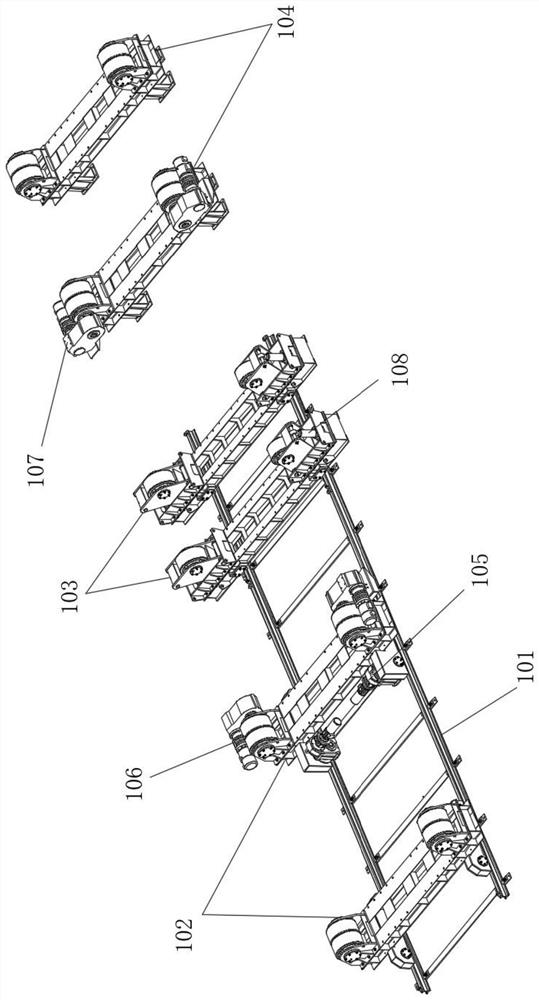

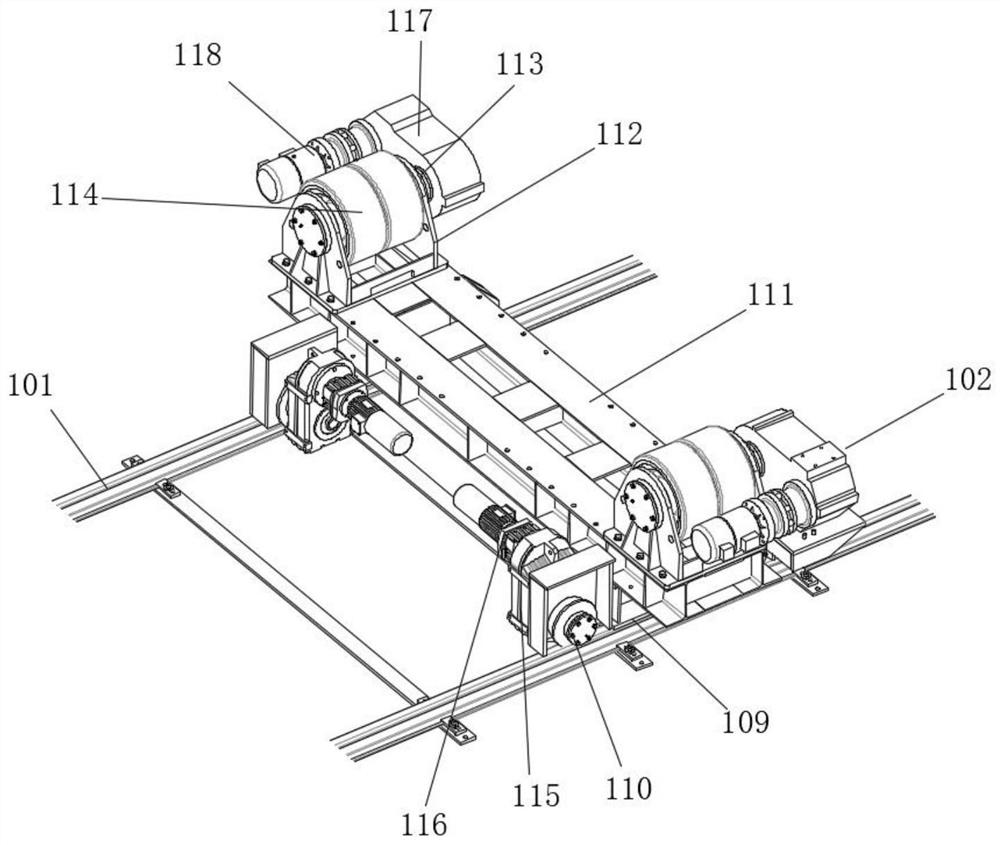

[0047] Embodiment: A large-scale pipeline welding method. In this method, the pipeline is placed on the welding roller frame. The gantry welding frame is set above the pipeline. A first welding torch that can be lifted is installed under the gantry welding frame, and the first welding torch is lifted to the pipeline. On the surface, the welding roller frame drives the pipeline to rotate slowly to realize the outer ring seam welding of the pipeline; the gantry welding frame is set on the rolling foot frame, and the outer longitudinal seam welding of the pipeline is realized through the movement of the gantry welding frame; The welding arm of the circular seam welding machine and the inner circular seam welding machine is equipped with a second welding torch, which extends into the pipeline, and the welding roller frame drives the pipeline to rotate slowly to realize the inner circular seam welding of the pipeline.

[0048] Among them, for the outer ring seam, the specific weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com