Czochralski single crystal charging method

A single crystal and charging technology, which is applied in the directions of single crystal growth, single crystal growth, and polycrystalline material growth, etc., can solve problems such as furnace accidents, reduced service life and safety, and longer time for feeding materials, so as to avoid Accidents, rapid chemical accidents, and the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention can be better understood from the following examples.

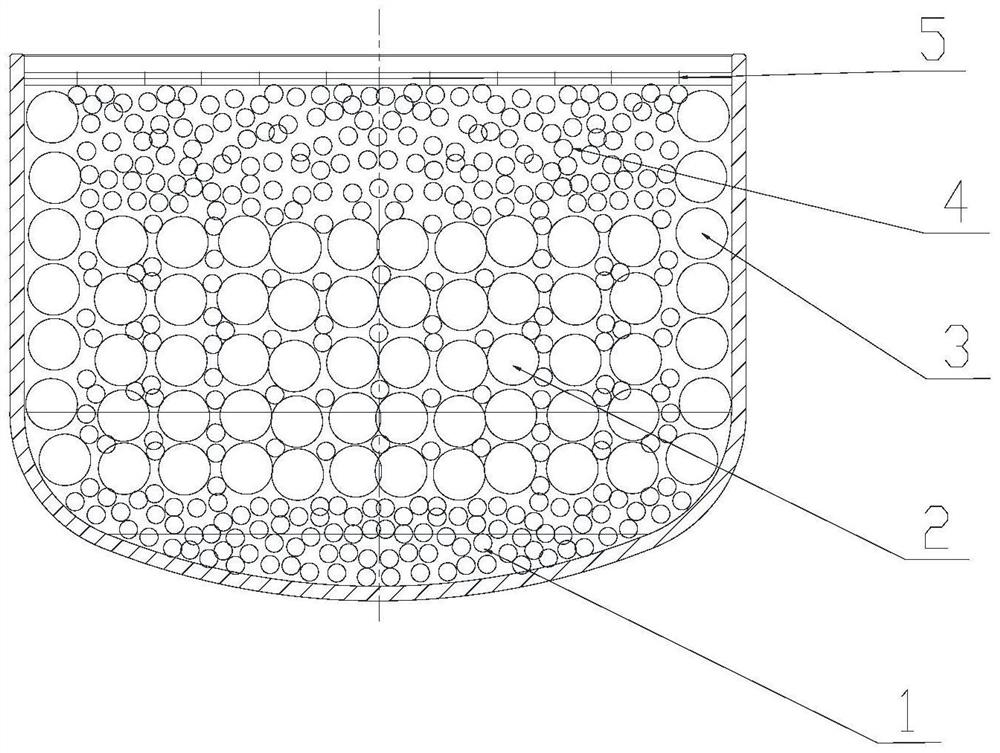

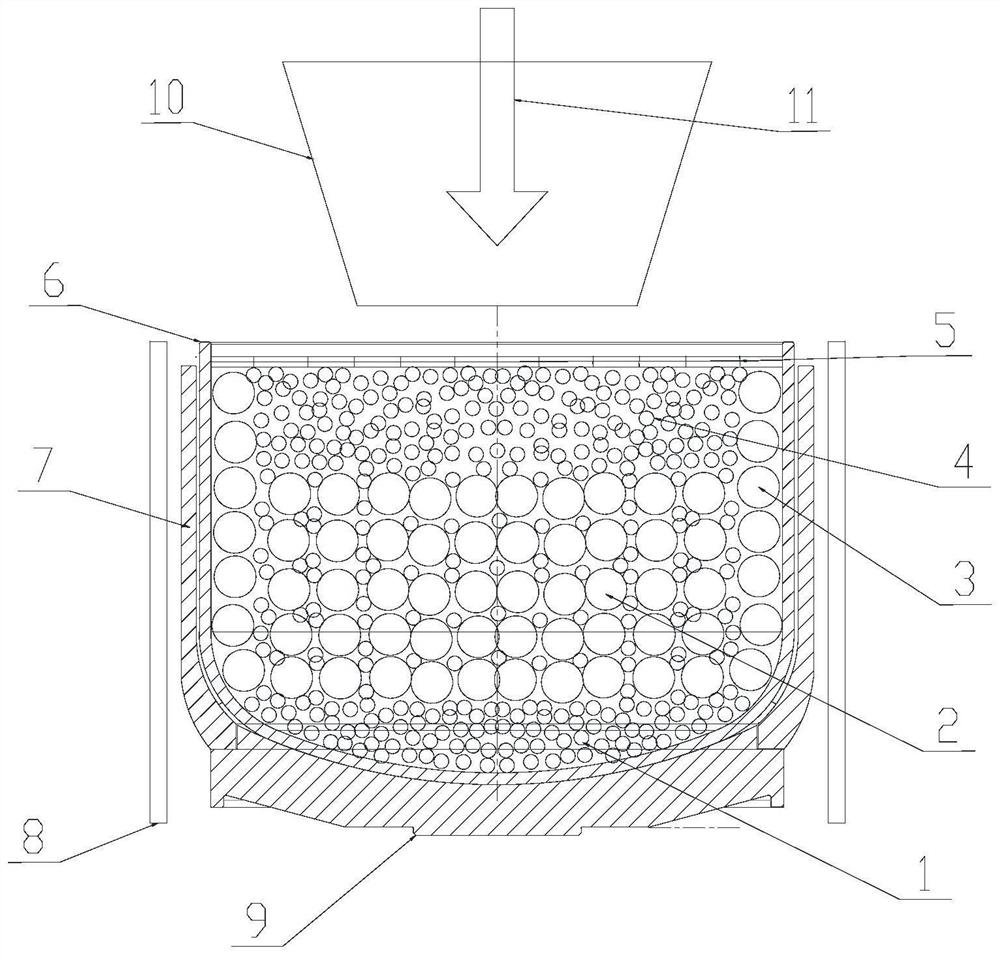

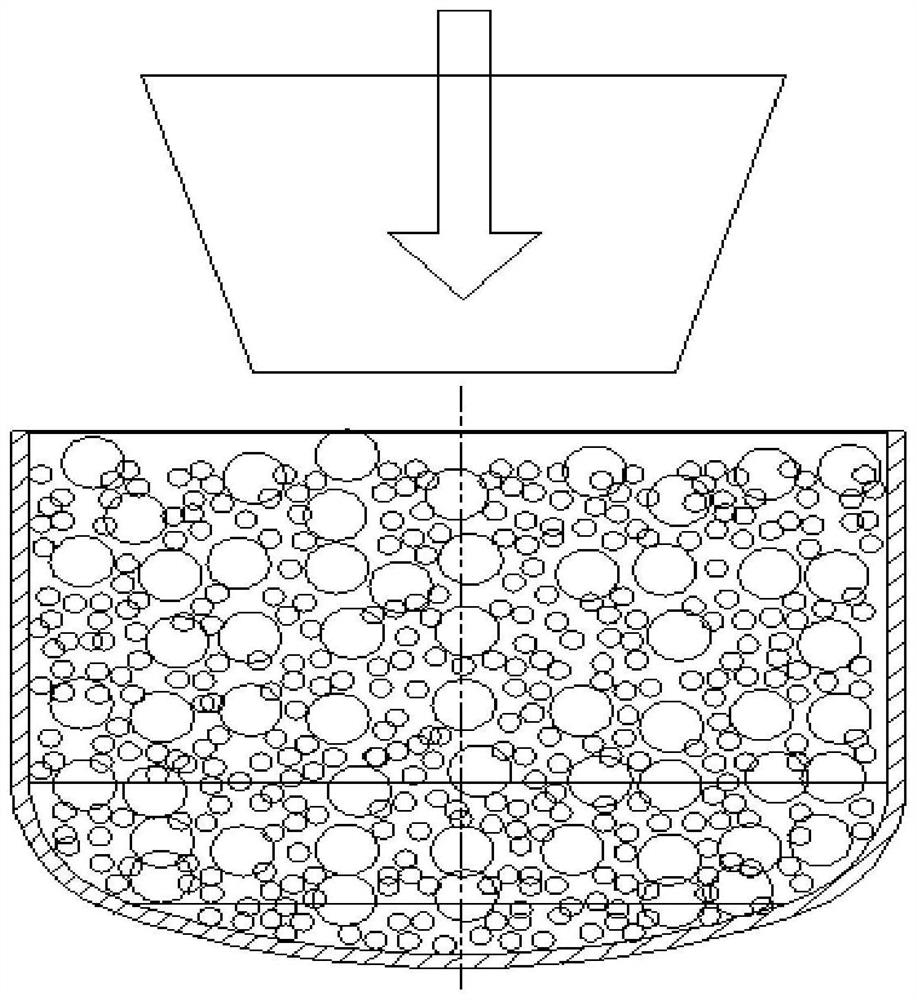

[0024] Such as figure 1 As shown, the Czochralski single crystal charging process of the present invention performs regional configuration of silicon materials of different shapes, and the specific steps are as follows:

[0025] First, fill small material at the bottom of the quartz crucible to form a small material bottom layer 1 with a thickness of 80-120 mm.

[0026] Subsequently, on the top of the small material bottom layer 1, the large material is stacked successively, and when each layer of large material is stacked, the gap of the large material is filled with the small material to form the composite layer 2 of the large and small material. When stacking the composite layer 2 of large and small materials, pay attention to the contact between the periphery of the composite layer 2 of large and small materials and the inner wall of the crucible, and use large materials to be stacked clo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com