Constant-speed smearing mechanism suitable for applying paste dressing

A paste and coating technology, which is applied in the processing of textile materials, mechanical cleaning, textile processing machine accessories, etc., can solve the problems of uneven dressing, bacteria generation, air-drying and condensation of paste, and achieve good cleaning effect, The effect of uniform absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

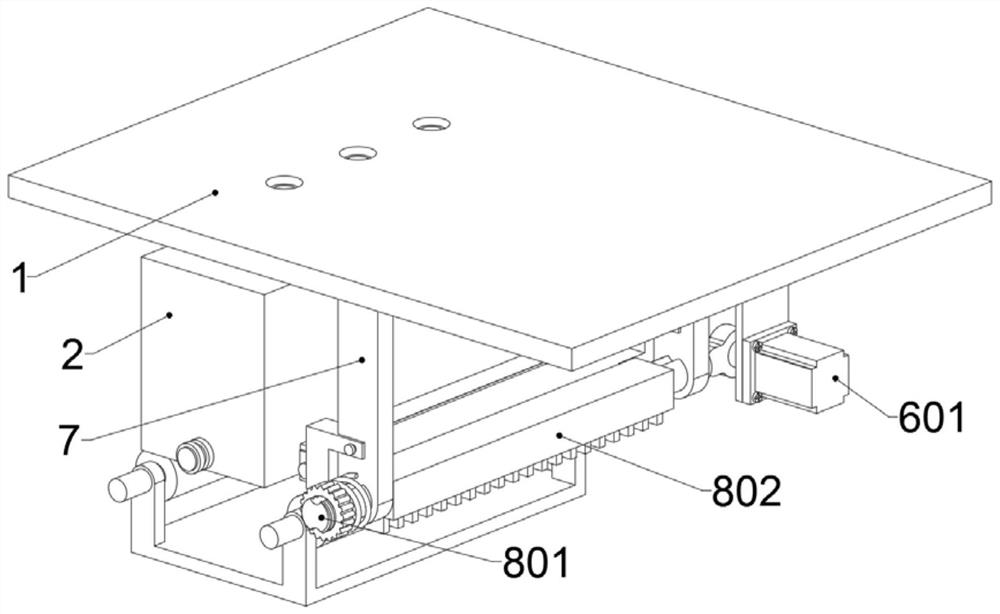

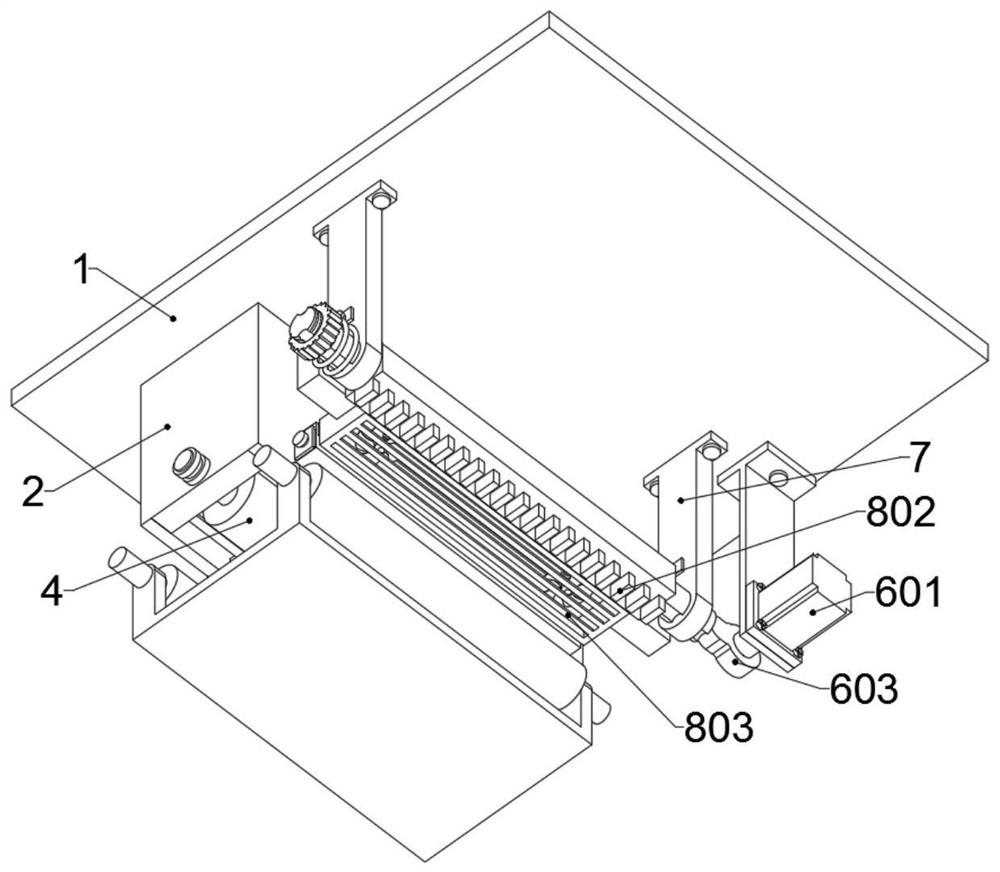

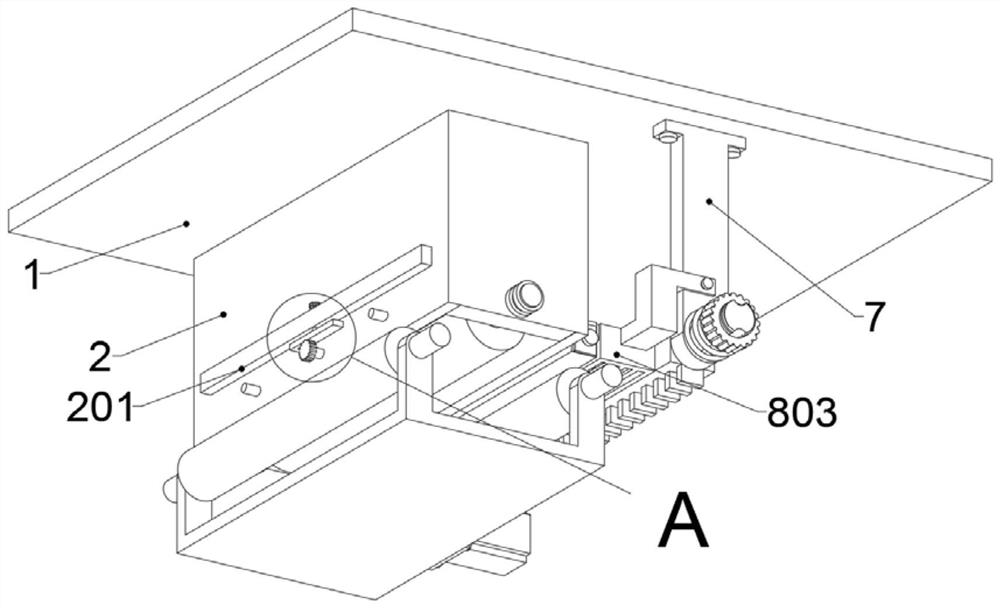

[0068] as attached figure 1 to attach Figure 15 Shown:

[0069] The present invention provides a uniform-speed coating mechanism suitable for coating paste dressings, including a support plate 1;

[0070] The support plate 1 is a rectangular structure;

[0071] The first protective shell 2, the first protective shell 2 is installed on the bottom of the support plate 1;

[0072] A spraying mechanism 3, the spraying mechanism 3 is installed above the inner side of the first protective shell 2;

[0073] A smearing structure, the smearing structure is installed on the bottom inside the first protective shell 2;

[0074] Auxiliary scraping mechanism 5, the auxiliary scraping mechanism 5 is installed on the outside of the first protective shell 2;

[0075] Extrusion mechanism 6, extrusion mechanism 6 is installed on the bottom of support plate 1;

[0076] Support block 7, support block 7 is installed on the bottom of support plate 1;

[0077] Dust removal mechanism 8, dust r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com