Water conservancy project water delivery ditch wall scraping and sweeping robot

A technology for water conservancy projects and water delivery ditches, which is applied in earth movers/excavators, non-rotational vibration suppression, construction, etc., and can solve the problem of affecting the cleaning operation of the ditch wall by the scraping robot, affecting the normal operation of the device, and the scraping robot To avoid problems such as dumping, achieve the effect of reducing impact, prolonging service life, and scraping thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

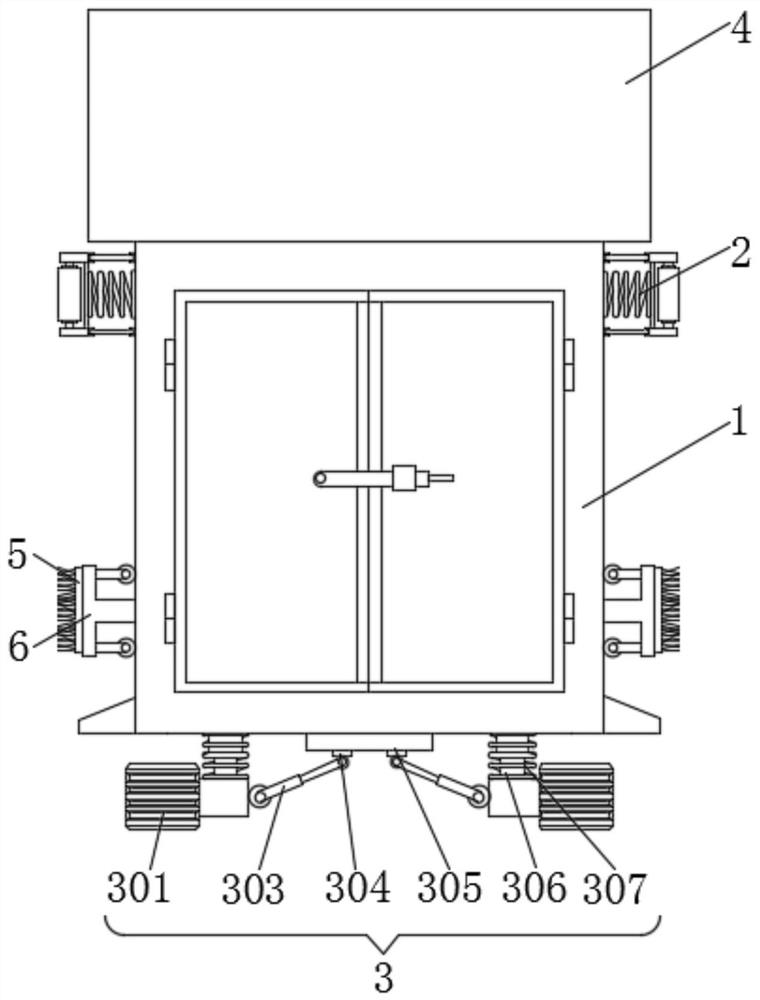

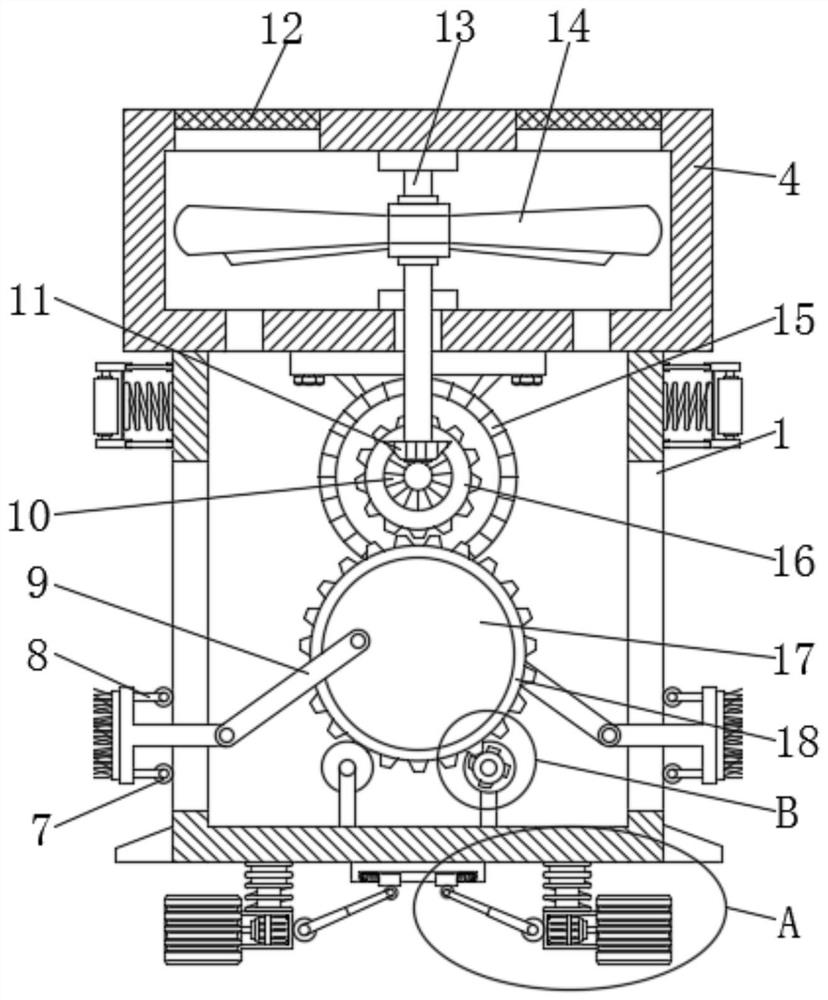

[0038] Example 1, such as figure 1 , 2 , 5, connect the displacement motor 302 to the power supply, when the device is running, the wheels 301 are in contact with the ground at this time, the wheels 301 are pushed by the extrusion of the ground, and then the displacement motor 302 is driven by the wheels 301 to push the motor compartment 309 for displacement, the motor compartment 309 drives the telescopic sleeve 306 to shrink, and then squeezes the spring B307 to shrink, and the motor compartment 309 drives the telescopic rod 303 to move at the same time, and the telescopic rod 303 pushes the slider 304 inside the chute 305 Sliding, and at the same time, the slider 304 drives the spring C308 to shrink or stretch, so that each wheel 301 can independently move up and down and absorb and relieve the extrusion force of the ground, thereby ensuring the structure of the device compartment 1 Stable, so that the device can be closely attached to the ditch wall, and realize the funct...

Embodiment 2

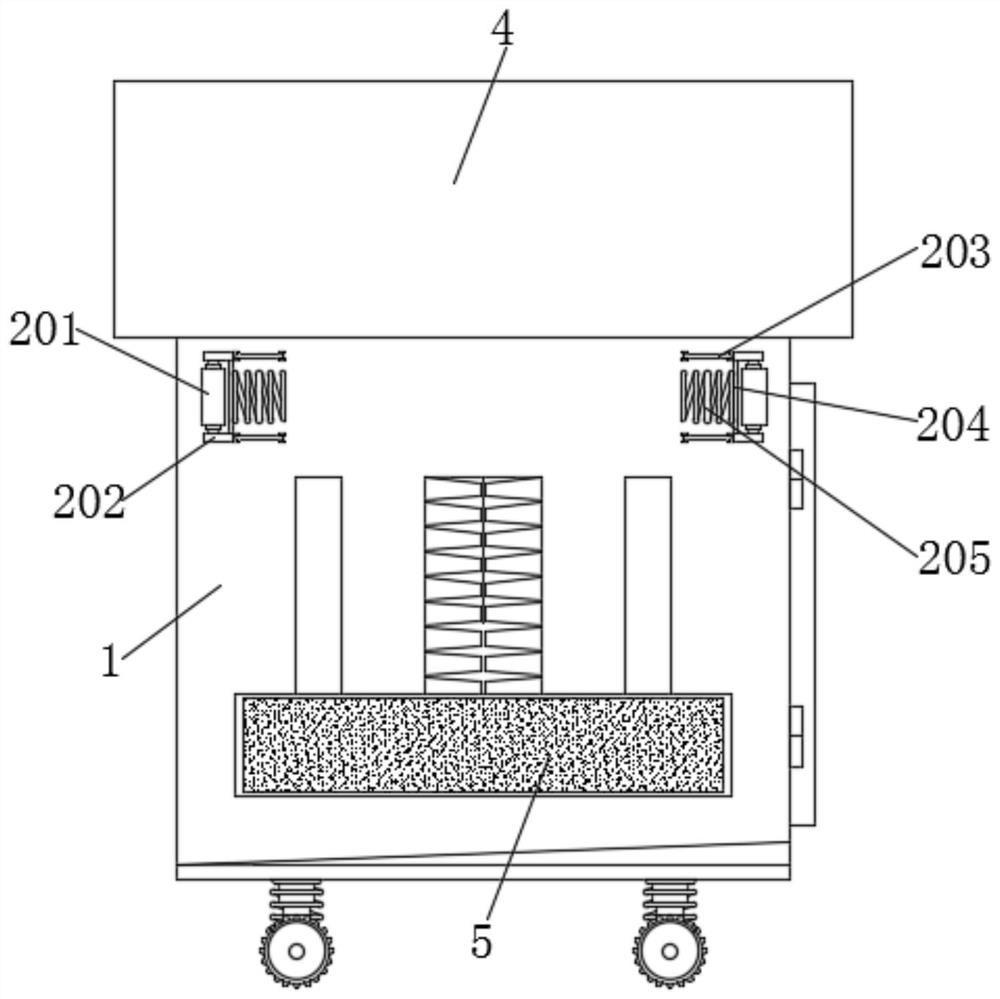

[0039] Example 2, such as Figure 1-4 As shown, when the device is in the moving state, the balance wheel 201 is attached to the ditch wall at this time, and at this time, a pressing force is generated on the balance wheel 201 through the ditch wall, and the axis between the balance wheel 201 and the hinge rod B202 is so that the balance wheel 201 can roll on the ditch wall, and the extrusion force of the ditch wall is transmitted to the positions of the hinged rod B202 and the hinged rod C203, and the hinged rod B202 and the hinged rod C203 are hinged, which can follow The position of the ditch wall needs to be adjusted, and the further extrusion force is transmitted to the position of the spring A205, so that the spring A205 shrinks, and at the same time, under the action of the rebound force of the spring A205, the hinge rod B202 is reversely pushed to drive the balance wheel 201 to fit the ditch wall , so as to ensure the stability of the device operation.

[0040] Workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com