Rigid-bone homogeneous external wall panel and manufacturing process thereof

A manufacturing process and technology of exterior wall panels, applied to walls, ceramic products, and other household appliances, etc., can solve problems such as inconsistent temperature deformation, falling off, rain erosion, etc., to avoid deformation and cracking, reduce concentrated deformation, and reduce concentrated stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1 A kind of rigid bone homogeneous exterior wall panel

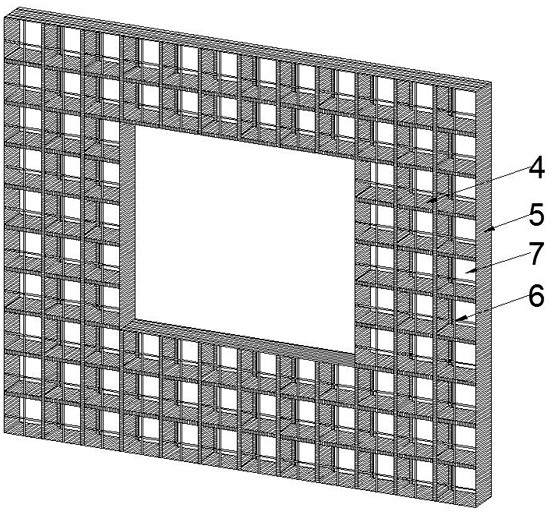

[0067] Such as Figure 1-Figure 7 As shown together, the present invention provides a rigid bone homogeneous exterior wall panel, which includes a bottom protective layer 1 , a middle rigid frame layer 2 and a top layer 3 .

[0068] The bottom protective layer 1 is an inorganic cement-based slurry layer.

[0069] The inorganic cement-based slurry layer is composed of the following components in parts by weight: 40 parts of cement, 40 parts of river sand, 20 parts of water, 0.2 part of fiber, and 0.1 part of powder glue.

[0070] The bottom protective layer 1 has a thickness of 10-25mm.

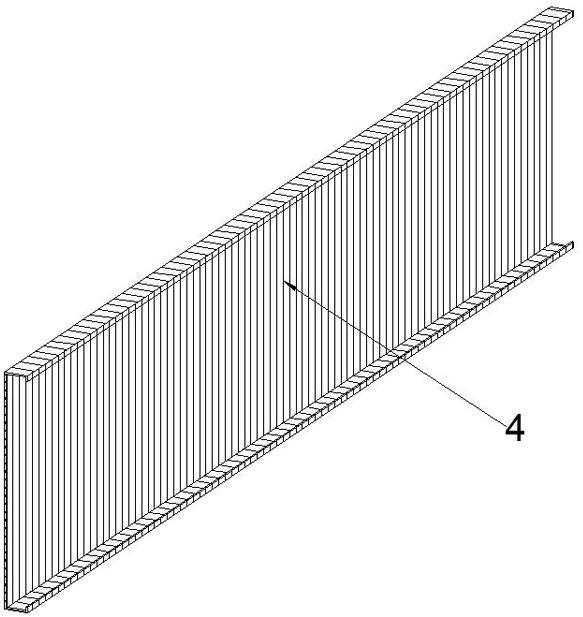

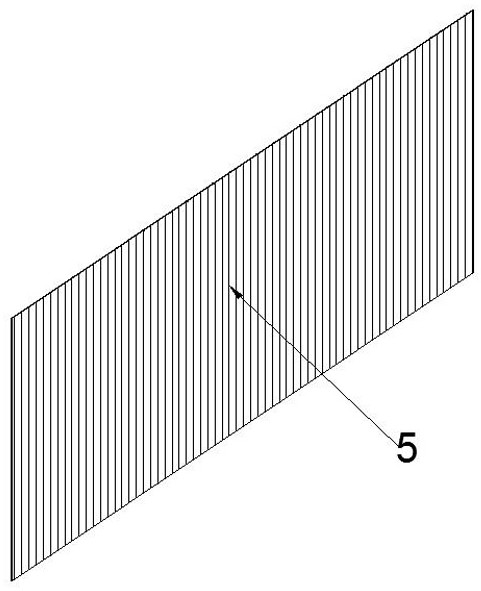

[0071] The middle rigid frame layer 2 includes a rigid skeleton formed by connecting and combining C-shaped ribs 4 , straight ribs 5 and tension and compression rods 6 , and the rigid skeleton is a three-dimensional rigid space structure system.

[0072] The C-shaped fins 4 are arranged in vertical and horizontal row...

Embodiment 2

[0082] Embodiment 2 A manufacturing process of a rigid bone homogeneous exterior wall panel

[0083] The invention provides a manufacturing process of a rigid bone homogeneous exterior wall panel, which specifically includes the following steps:

[0084] Step 1. Make the rigid skeleton. According to the construction drawing of the rigid skeleton of the single-piece exterior wall panel, the C-shaped ribs 4 and the straight-shaped ribs 5 are cut, and the galvanized sheet is mechanically cold-processed and extruded according to the size, and assembled and welded in a factory , connecting and interspersing, the rigid skeleton is formed by connecting and combining C-shaped ribs 4, straight plate-shaped ribs 5 and tension and compression rods 6;

[0085] Step 2, making metal hanging components and connecting components for lifting and installing exterior wall panels;

[0086] Step 3: Apply release agent on the platform, and first pad the first layer of inorganic cement-based slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com