Air compressor capable of discharging dust and dissipating heat through external expansion

An air compressor and radiator technology, applied in the field of air compressors, can solve the problems of reducing the maintenance efficiency of the air compressor, affecting the normal operation of the air compressor, and affecting the production of enterprises, so as to reduce manual participation, improve service life, reduce The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

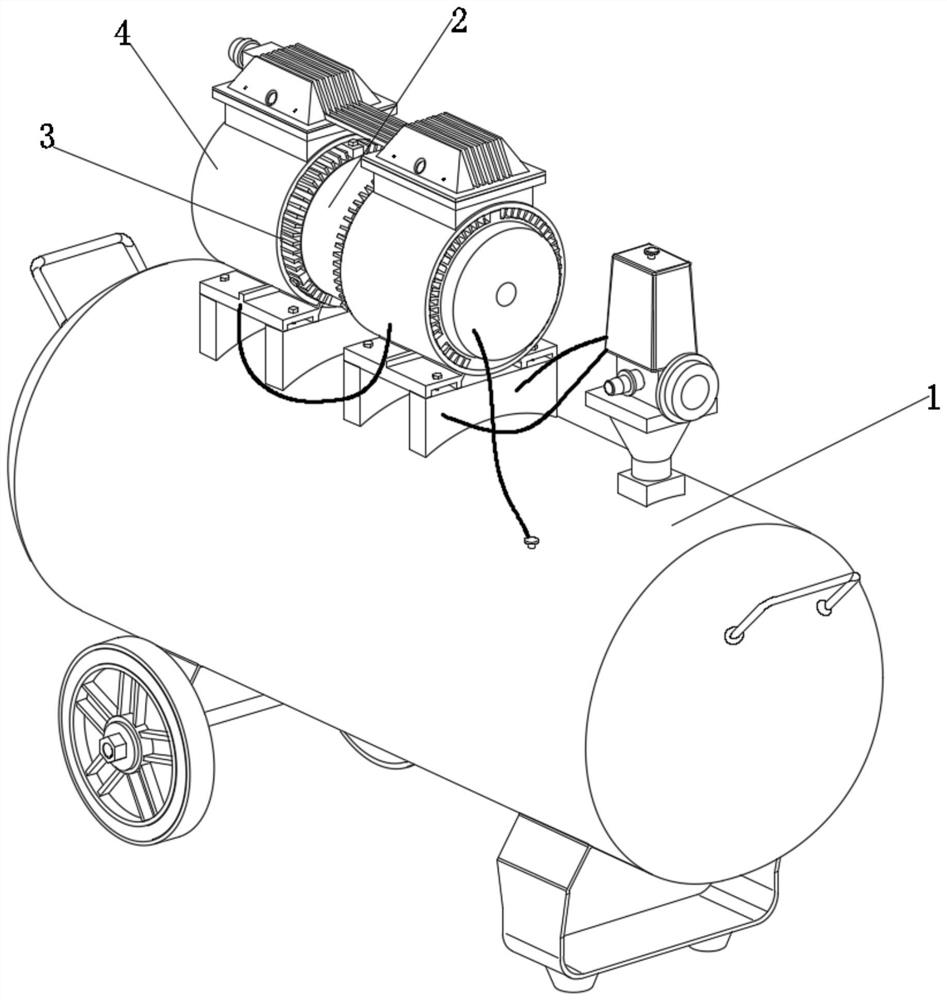

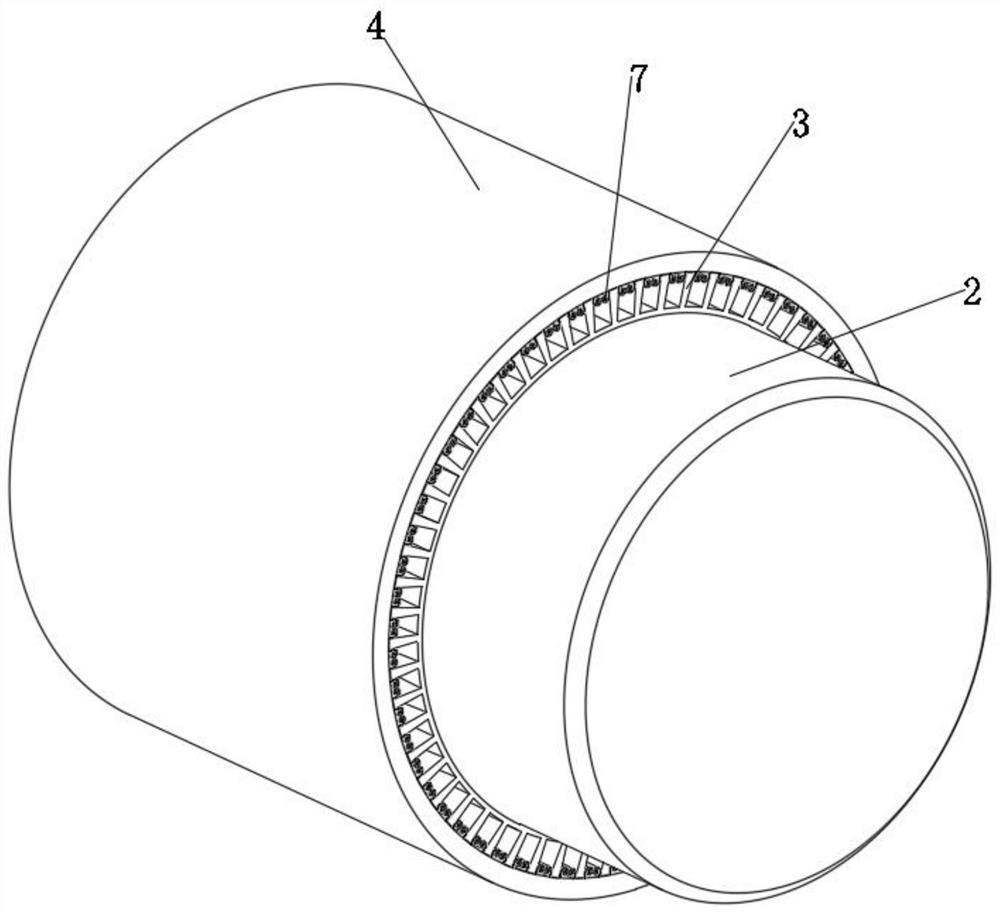

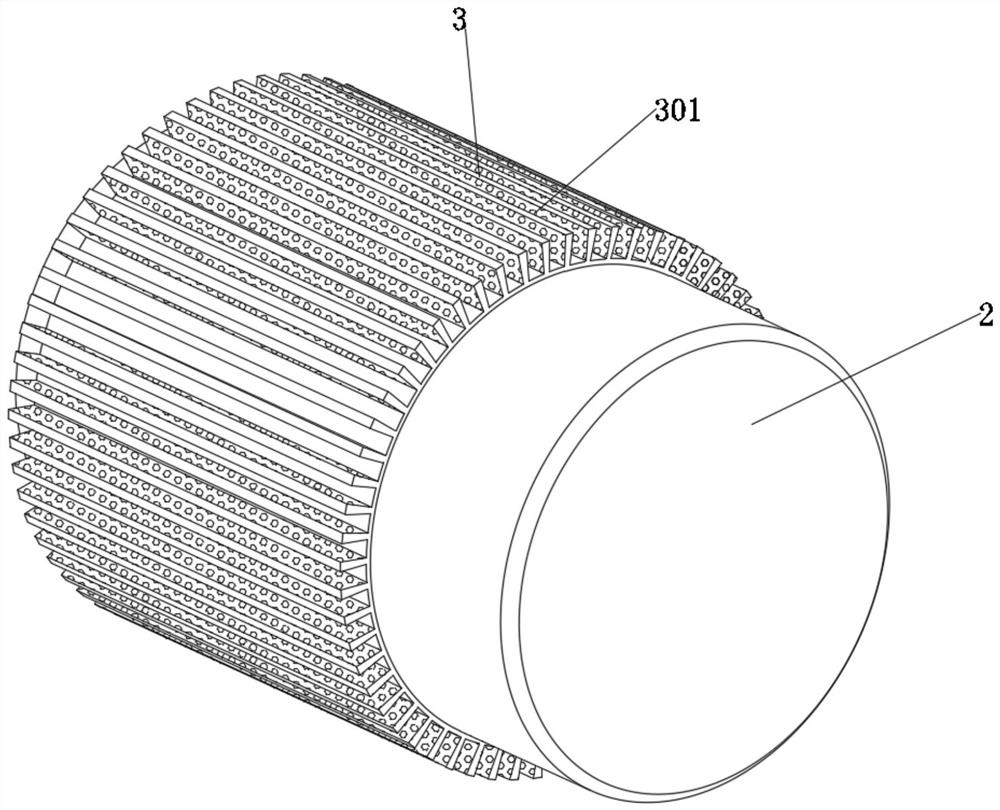

[0046] see Figure 1-10 , an air compressor for external expansion, dust discharge and heat dissipation, comprising an air compressor body 1, a radiator body 2 is installed on the upper end of the air compressor body 1, and a plurality of circumferentially distributed cooling fins are fixedly connected to the outer end of the radiator body 2 fin 3, the outer end of the radiator body 2 is fixedly connected with a uniform heat dissipation ring 4 located on the outside of the heat dissipation fin 3, the heat dissipation fin 3 is provided with an expansion cavity, and the side walls of the heat dissipation fin 3 are provided with a plurality of expansion chambers. Through the heat dissipation fin hole 301, the inner wall of the uniform heat dissipation ring 4 is fixedly connected with a plurality of positioning temperature conducting beads 6, and the positioning temperature conducting bead 6 extends into the expansion cavity near the end of the heat dissipation fin 3, and the outer...

Embodiment 2

[0054] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to Figure 6-8 The heat dissipation conduction middle layer 402 is fixedly connected with a plurality of temperature-sensitive adhesive contact pieces 7, and the end of the heat-sensitive adhesive contact piece 7 close to the heat dissipation fin 3 penetrates the heat dissipation conduction bottom layer 401 and is bent in a spiral shape. The outside of the connection between the sheet 7 and the heat-dissipating bottom layer 401 is fixedly connected with a temperature-insulating strip 8, and the temperature-sensitive adhesive contact sheet 7 is blocked by the temperature-insulating strip 8 to sense the temperature of the heat-dissipating conductive bottom la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com