Spectral confocal-based hemispherical resonator gyroscope precision assembly device and adjustment method thereof

A hemispherical resonant gyroscope and spectral confocal technology, applied in the field of inertial measurement sensors, can solve the problems of no resonant gyroscope, no solution, and high requirements for gap consistency, and achieve the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

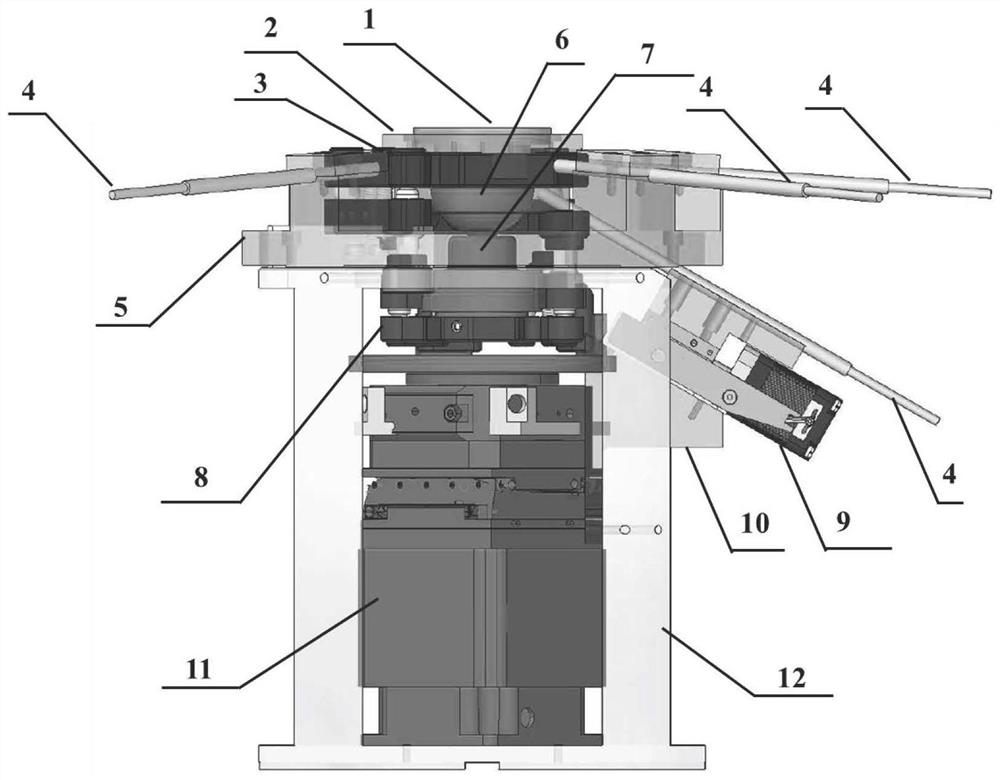

[0036] The precision assembly device of hemispherical resonator gyroscope based on spectral confocal, such as figure 1 As shown, it includes base 1, base fixing tool 2, base attitude adjustment tool 3, multiple color confocal sensors 4, horizontal color confocal sensor bracket 5, resonator 6, resonator fixing tool 7, resonator Attitude adjustment tooling 8, 30-degree direction color confocal sensor motion translation stage 9, 30-degree direction color confocal sensor fixing bracket 10, multi-degree-of-freedom positioning platform and gyro assembly integrated tooling 11, the harmonic oscillator is fixed on by the harmonic oscillator fixing tooling On the harmonic oscillator attitude adjustment tool, the harmonic oscillator attitude adjustment tool is fixed on the multi-degree-of-freedom positioning platform, and the multi-degree-of-freedom positioning platfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com