Remote optical cable and preparation method thereof

A technology for optical cables and sub-cables, applied in the field of remote optical cables and its preparation, can solve the problems of complex laying environment, tensile resistance, water resistance, anti-rat bite and impact resistance defects, so as to improve the laying range and comprehensive deployment ability , Improve the anti-rat performance and tensile performance, and avoid the effect of large attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

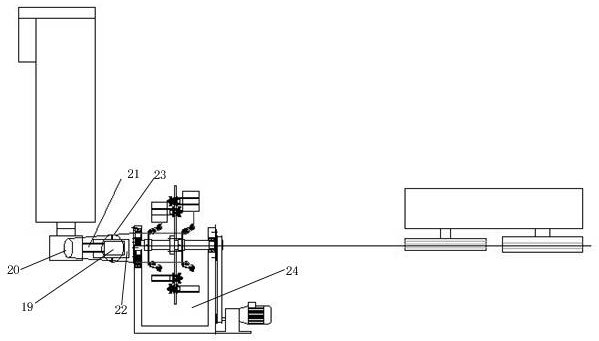

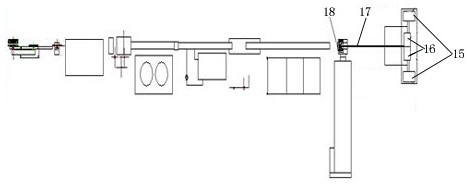

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

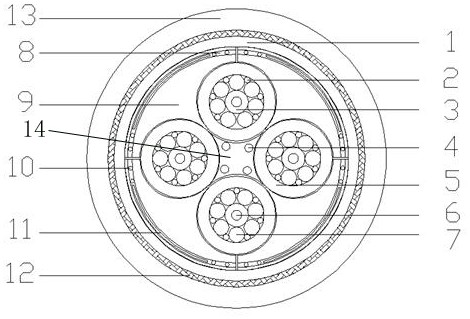

[0028] Such as figure 1 As shown, the present invention is a remote optical cable, including a positioning framework 14 located in the center of the cable, and supporting frameworks 9 are arranged symmetrically along the four corners of the positioning framework, and circular grooves are formed between the positioning framework and each supporting framework. Place the sub-cable in the circular groove to form a cable core; the inner sheath 1 is extruded outside the cable core, the inner sheath is woven with an aramid yarn braiding layer 12, and the outer sheath 13 is extruded outside the aramid yarn braiding layer; The sheath, the braided layer of aramid yarn and the outer sheath are integrally formed. The sheath material has the property of preventing rat bites. The 360° wrapping of the braided layer of aramid not only improves the tensile perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com