Stacked photonic iii-v semi-conductor device

A III-V, semiconductor technology, applied in the field of stacked photonic III-V semiconductor devices, can solve problems such as residual current leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

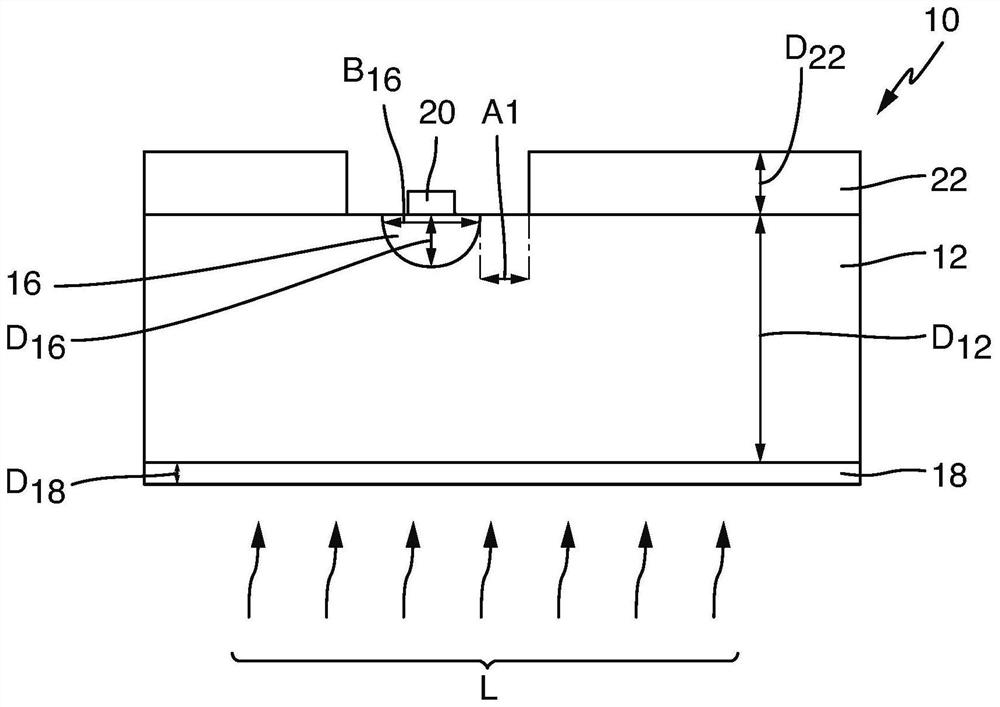

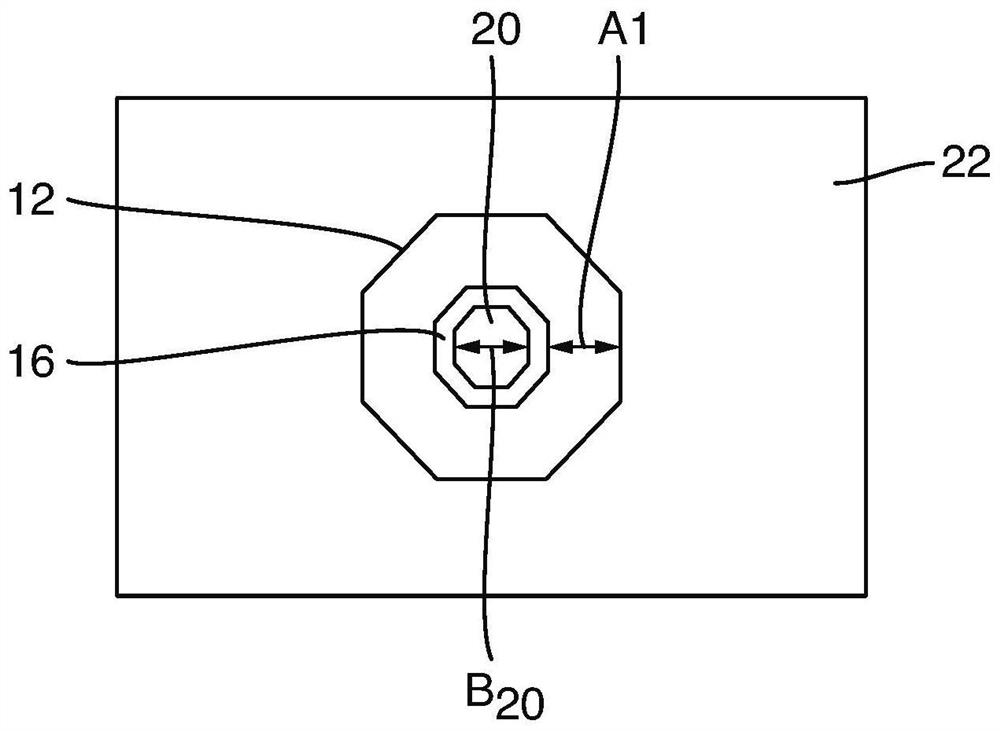

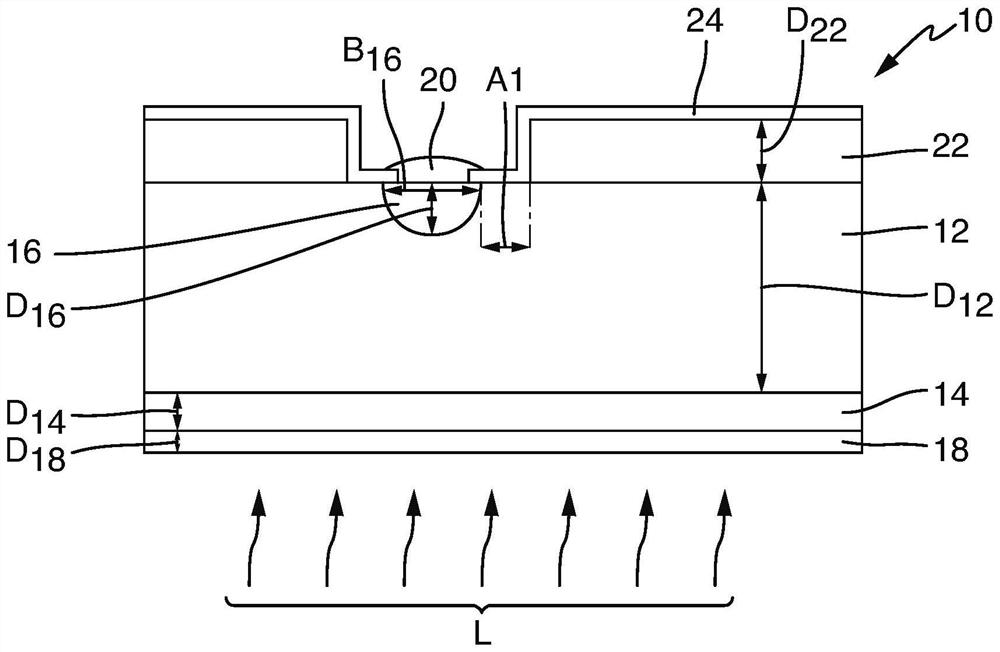

[0105] figure 1 The image in the figure shows a stacked photonic III-V semiconductor device 10 having an absorbing region 12, a highly doped first semiconductor contact region 16 and having a first metal connection layer 18, a second metal connection connection Layer 20 and III-V semiconductor passivation layer 22.

[0106] The absorption region 12 is doped with a second conductivity type with 8·10 11 cm -3 to 5·10 14 cm -3 A dopant at a low to very low dopant concentration, and has a first lattice constant and a layer thickness D12 of at least 80 μm (eg, 100 μm or 1000 μm).

[0107] On the underside of the absorption region 12 , a first metal connection layer 18 as a thin planar layer with a layer thickness D18 of up to 2 μm (eg 10 nm) follows in a material-bonding manner. metal layer. Alternatively (not shown), the metal connection layer 18 is configured in the form of strips or fingers or points.

[0108] The highly doped first semiconductor contact region 16 is of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com