Lifting type water-based coating processing device

A technology of water-based paint and processing equipment, which is applied in the direction of mixers, dissolvers, and mixers with rotating stirring devices, which can solve problems such as low uniformity, lower water-based paint quality, and insufficient filtration, so as to improve the grinding effect. The effect of thorough grinding and reducing the difficulty of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

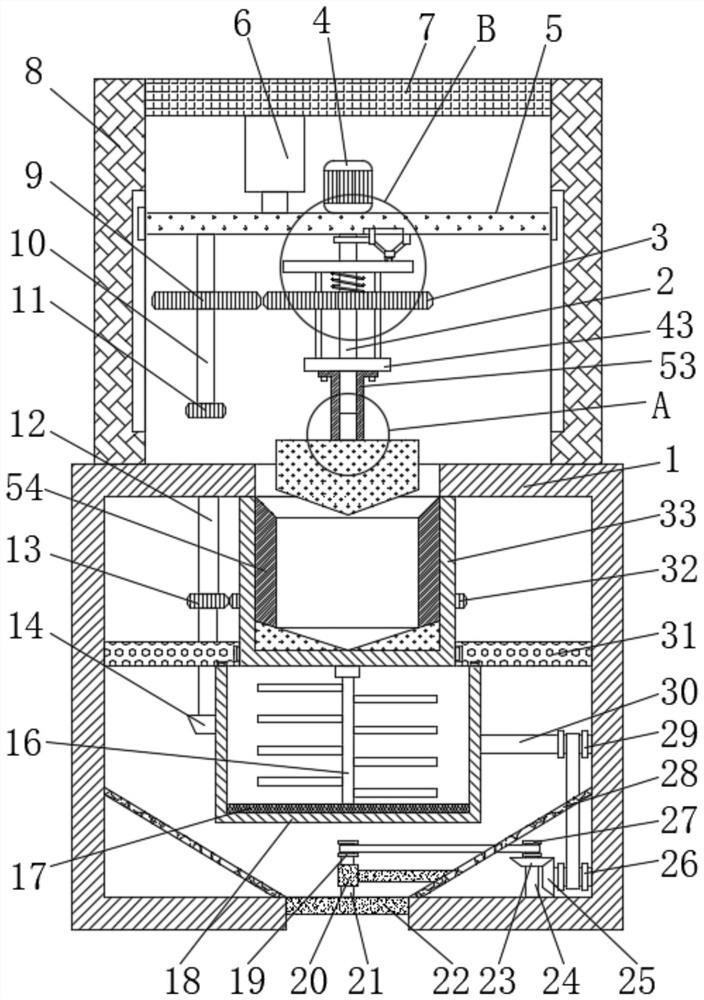

[0035] Embodiment 1: as figure 1 As shown, a lifting type water-based paint processing device includes a first box body 1, a support column 8 is welded on the left side of the top of the first box body 1, and a fixed plate 7 is fixedly connected to the top of the right side of the support column 8, and the fixed plate The bottom of 7 is fixedly connected with a push rod motor 6, the bottom of the push rod motor 6 is welded with a movable plate 5, the push rod motor 6 can be started to make the movable plate 5 move downward, and the right side of the bottom of the movable plate 5 is fixedly connected with a drive motor 4 , the driving motor 4 starts to make the first rotating shaft 2 rotate, the output end of the driving motor 4 is welded with the first rotating shaft 2, the outer ring of the first rotating shaft 2 is welded with the first gear 3, and the rotation of the first rotating shaft 2 can make the first gear 3 turn;

Embodiment 2

[0036] Embodiment 2: as figure 1 , Figure 5 , Figure 7 As shown; the bottom end of the first rotating shaft 2 is equipped with a grinding head 201, the inner walls of both sides of the first box 1 are fixedly connected with a support plate 31, and the inner ring of the support plate 31 is rotatably connected with a grinding box 33;

[0037] A first lifting disc 41 and a second lifting disc 42 are slidably installed on the first rotating shaft 2, the first lifting disc 41 is located at the upper part of the first gear 3, and the second lifting disc 42 is located at the lower part of the first gear 3, A push rod 43 is connected between the second lift plate 42 and the first lift plate 41, and the push rod 43 slides through the first gear 3, and between the first gear 3 and the first lift plate 41 is a Squeeze the spring 44, the lower part of the movable plate 5 is provided with a horizontal chute 45 along the radial direction of the first rotating shaft 2, and the end of the...

Embodiment 3

[0038] Embodiment 3: as figure 1 and Figure 5 As shown, the bottom end of the first rotating shaft 2 is equipped with a grinding head 201, the rotation of the first rotating shaft 2 can make the grinding head 201 rotate, and the raw material is ground, and the bottom left side of the movable plate 5 is connected with the second rotating shaft 10. The outer ring of the rotating shaft 10 is welded with a second gear 9, the rotation of the first gear 3 can make the second gear 9 rotate, the rotation of the second gear 9 can make the second rotating shaft 10 rotate, and the bottom end of the second rotating shaft 10 is welded with a third gear 11. The rotation of the second rotating shaft 10 can make the third gear 11 rotate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com