Automatic heliostat cleaning device

A technology for automatic cleaning and heliostats, applied in cleaning methods and appliances, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems affecting the economics of solar thermal power plants, high time costs, and low cleaning efficiency, etc. problems, to achieve the effect of ensuring thermal power generation efficiency, reducing labor costs, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

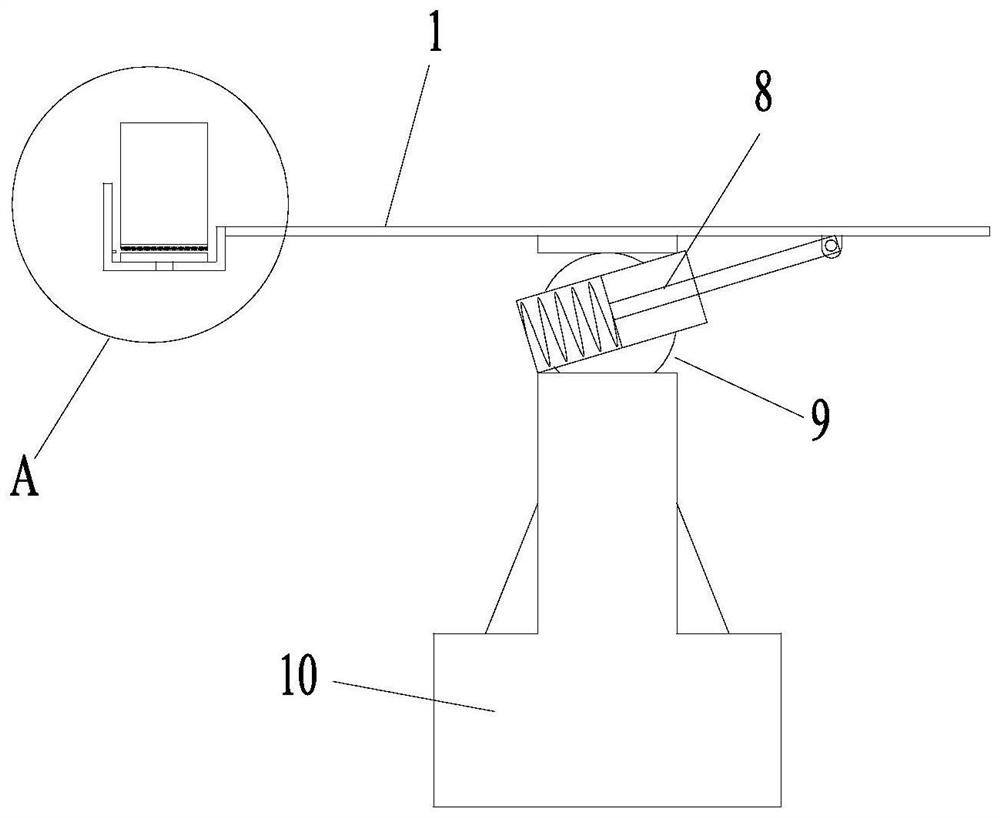

[0069] refer to figure 1 As shown, this embodiment provides an automatic cleaning device for heliostats, including a cleaning module and a storage limit module, the storage limit module is set at the end of the heliostat 1, and the heliostat includes a first end and a second end. For the two ends, during the rotation process of the heliostat, the relative position between the first end and the second end in the height direction will change. Among them, the bottom of the heliostat 1 in this embodiment is connected to the top of the heliostat column 10 through the attitude adjustment mechanism, and the tracking of the sun is realized through the attitude adjustment mechanism, and then the height direction between the first end and the second end is realized. change in relative position.

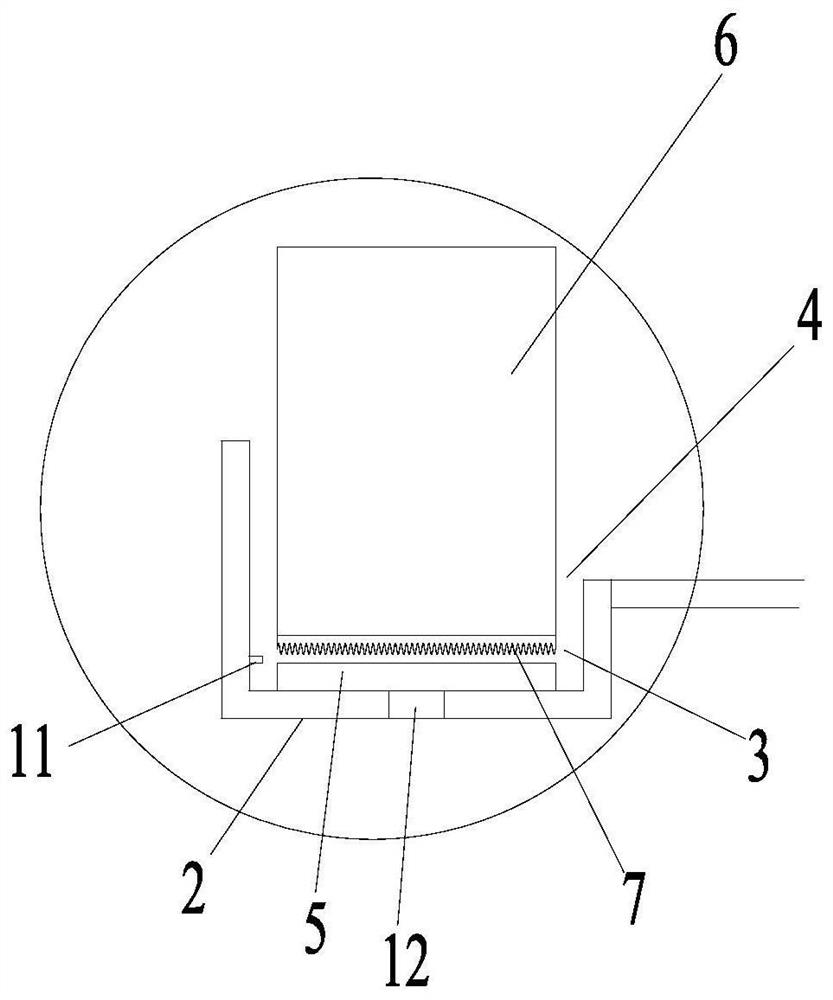

[0070] Specifically, refer to figure 2 As shown, the storage limit module in this embodiment includes a storage cavity 3, the storage cavity 3 is used to store and limit the cleaning module,...

Embodiment 2

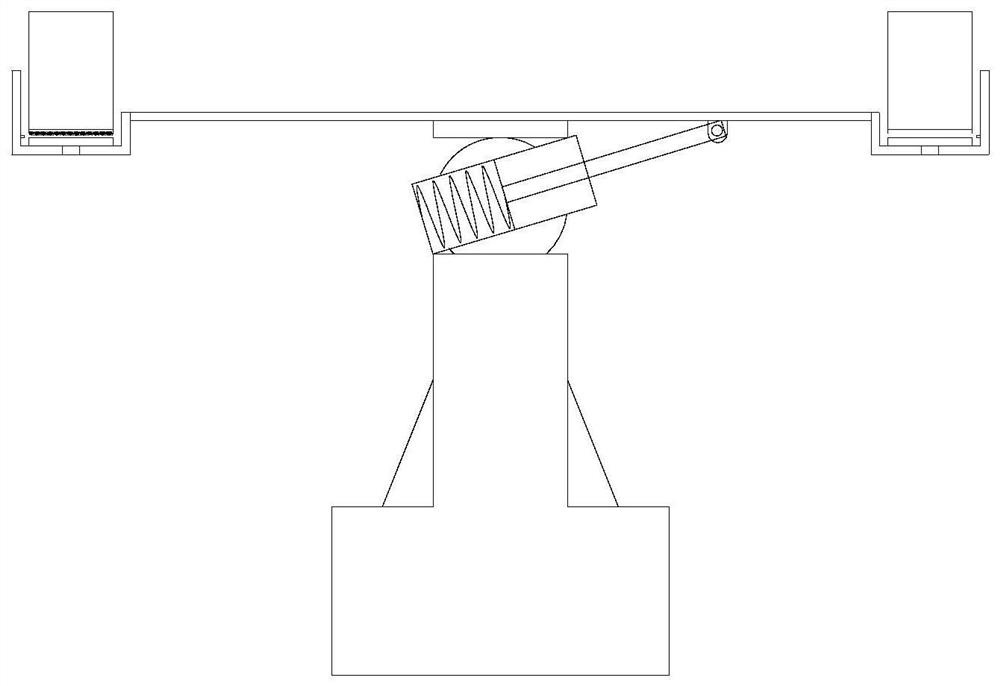

[0089] refer to Figure 4 As shown, this embodiment provides an automatic cleaning device for heliostats. The structural difference between the automatic cleaning device for heliostats in this embodiment and the automatic cleaning device for heliostats in Embodiment 1 is that: the automatic cleaning device for heliostats in this embodiment There are two storage limit modules, and the two storage limit modules are respectively arranged at ends on opposite sides of the heliostat 1 . In specific use, the cleaning module can be accommodated in any storage limit module.

[0090] Specifically, when the automatic cleaning device for heliostats in this embodiment is used, firstly, the cleaning module is placed in any storage limit module, and then the cleaning module is passed through after the first expansion and contraction member 5 absorbs water and expands by injecting water. The opening 4 is ejected to the outside of the storage cavity 3, and then the cleaning module slides on t...

Embodiment 3

[0094] refer to Figure 5-Figure 14 As shown, this embodiment provides an automatic cleaning device for heliostats. The structural difference between the automatic cleaning device for heliostats in this embodiment and the automatic cleaning device for heliostats in Embodiment 2 is that: the automatic cleaning device for heliostats in this embodiment The cleaning block 6 is provided with a water storage chamber 13, the top and the bottom of the water storage chamber 13 are provided with a water inlet 14 and a water outlet 15, and the water inlet 14 and the water outlet 15 are all connected with the water storage chamber 13, and the bottom of the cleaning block 6 is provided There is a cleaning pad 7, and the cleaning pad 7 is located directly below the water outlet 15; the cleaning module in this embodiment also includes an opening and closing assembly for controlling the opening and closing of the water inlet 14 and the water outlet 15.

[0095] Specifically, refer to Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com