Multi-angle cutting device for glass fiber reinforced plastic tube processing

A glass fiber and plastic pipe technology, applied in metal processing and other directions, can solve the problems of glass fiber reinforced plastic pipes that cannot be completely cut, operator fatigue, large angle error, etc., to facilitate processing, prevent personnel injury, and reduce strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

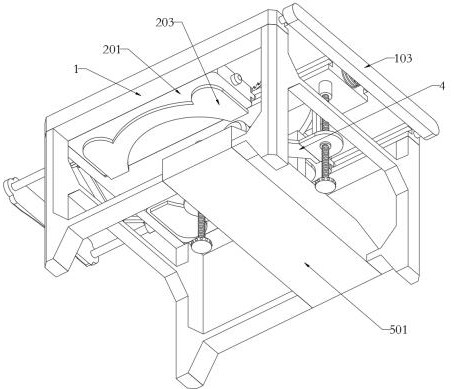

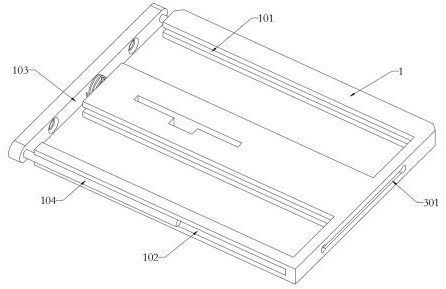

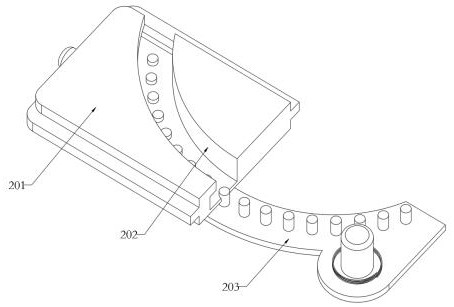

[0037] as attached figure 1 to attach Figure 10 Shown:

[0038] The invention provides a multi-angle cutting device for glass fiber reinforced plastic pipe processing, comprising:

[0039] Such as figure 1 , figure 2 and image 3 As shown, the frame body 1 is equipped with supporting legs at the edge position of the bottom of the frame body 1, and the side of the side baffle plate 103 of the frame body 1 is provided with a card slot, and the top of the frame body 1 is equipped with an adjustment mechanism 2, and the frame body 1 includes : chute 101, both sides of chute 101 are provided with grooves, and chute 101 is located at the top of frame body 1; Inner groove 102, inner groove 102 is a cylindrical structure, and inner groove 102 is located at Side; baffle plate 103, the movement of baffle plate 103 drives cross bar 104 to move inside groove 102, guarantees that baffle plate 103 moves horizontally, and baffle plate 103 is installed on the side of support body 1 by sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com