Oil-based high-temperature and high-density drilling fluid for drilling wall reinforced rock gas reservoir

A drilling fluid and high-density technology, used in wellbore/well components, earth-moving drilling, flushing wellbore, etc., can solve problems such as wellbore collapse, fracture leakage of high-density oil-based drilling fluid, etc. Simple maintenance and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In an embodiment of the present invention, an oil-based high-temperature, high-density drilling fluid for drilling wall-strengthened rock gas reservoirs, the raw material composition of the oil-based high-temperature, high-density drilling fluid is as follows;

[0040] Oil phase: 80-95 parts;

[0041] Main emulsifier: 2 to 4 parts;

[0042] Co-emulsifier: 2 to 4 parts;

[0043] Wetting agent: 2 to 4 parts;

[0044] Organic soil: 0.5 to 3 parts;

[0045] Filtrate reducer: 2 to 6 parts;

[0046] Flow regulator: 0 to 3 parts;

[0047] Pressure-bearing plugging agent while drilling: 2 to 8 parts;

[0048] Composite plugging agent with variable particle size: 1 to 4 parts;

[0049] Lime: 2 to 4 parts;

[0050] Ultrafine calcium carbonate: 3 to 5 parts;

[0051] 25% CaCl2 brine: 5-20 parts;

[0052] API standard barite: aggravated to 2.05~2.3g / cm3;

[0053] The pressure-bearing plugging agent while drilling is a well wall strengthening agent that improves the pressu...

Embodiment 2

[0067] An oil-based high-temperature and high-density drilling fluid system for shale gas reservoirs with wall strengthening while drilling. The raw materials are composed in parts by weight as follows:

[0068] Oil phase: 80-85 parts;

[0069] Main emulsifier: 3 to 3.5 parts;

[0070] Co-emulsifier: 3 to 3.5 parts;

[0071] Wetting agent: 3 to 4 parts;

[0072] Organic soil: 2 to 3 parts;

[0073] Filtrate reducer: 4 to 5 parts;

[0074] Flow regulator: 1 to 2 parts;

[0075] Pressure-bearing plugging agent while drilling: 5-6 parts;

[0076] Composite plugging agent with variable particle size: 3 to 4 parts;

[0077] Lime: 2 to 3 parts;

[0078] Ultrafine calcium carbonate: 3 to 4 parts;

[0079] 25% CaCl2 brine: 18-20 parts;

[0080] API standard barite: aggravated to 2.05-2.3g / cm3.

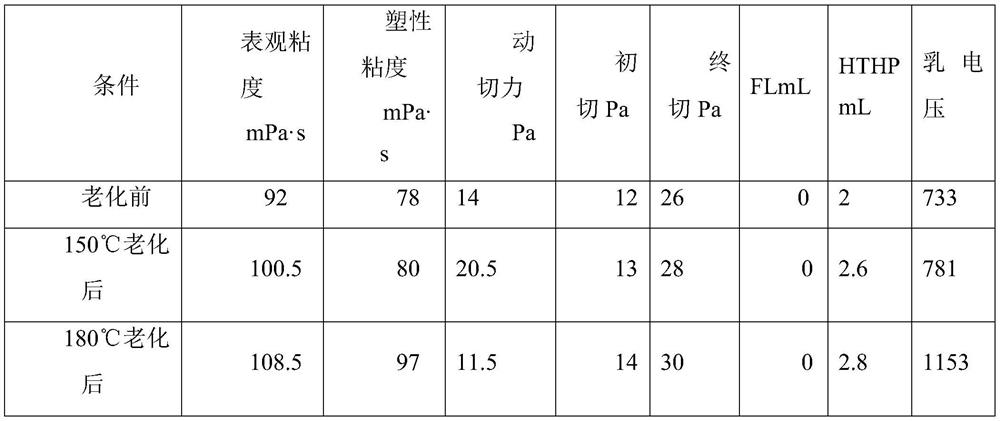

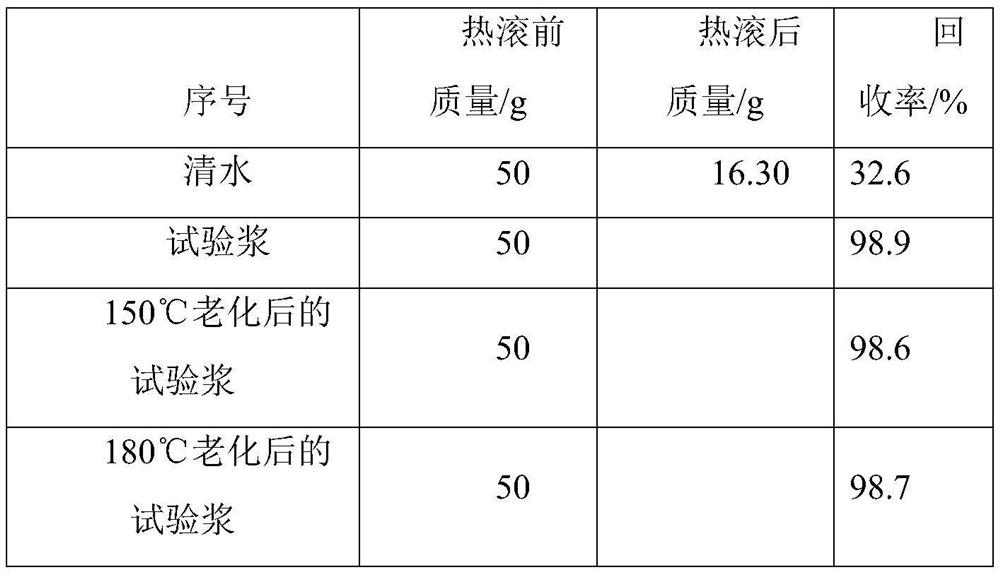

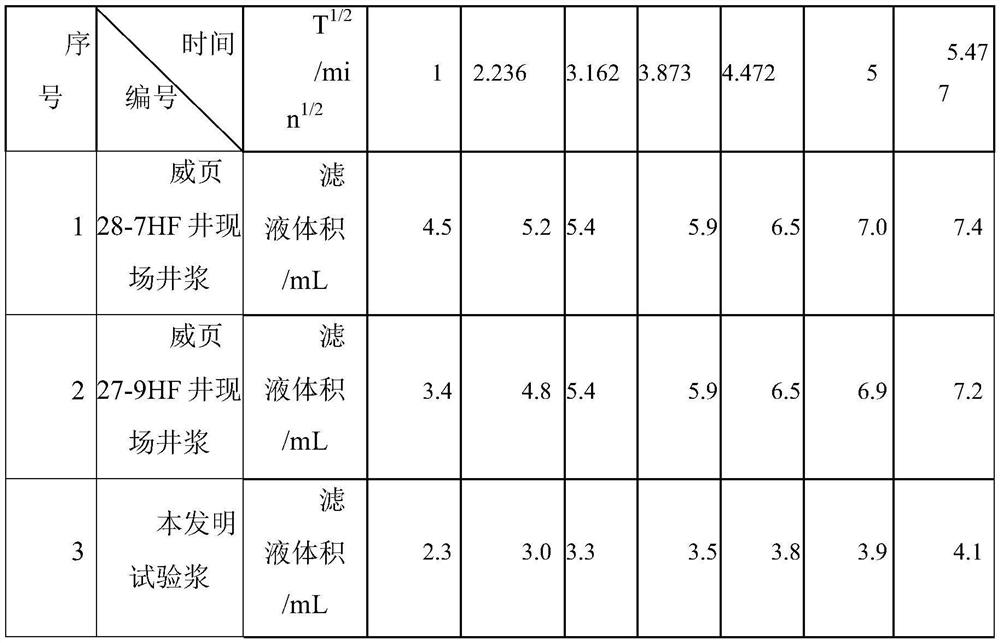

[0081] An oil-based high-temperature and high-density drilling fluid system for wall-strengthening while drilling shale gas reservoirs. The density can be adjusted within the range o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com