Diesel oil-based drilling fluid with high saline water pollution resistance and preparation method thereof

A diesel-based drilling fluid and brine technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of HTHP large water loss, poor rheological control, poor fluidity of drilling fluid, etc., to reduce labor intensity, Good emulsification stability, the effect of reducing solid phase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

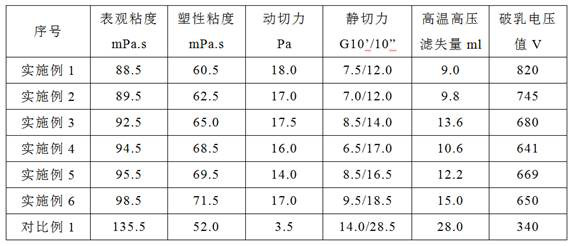

Examples

Embodiment 1

[0030] As the best embodiment of the present invention, diesel oil, composite emulsifier, calcium chloride brine, calcium oxide, organic bentonite, high temperature resistant fluid loss reducer, and density regulator are prepared in parts by weight, and the components are in parts by weight The ratio is 25:2:4:1.7:1.5:2.5:64.3. A preparation method of high resistance to salt water pollution diesel base drilling fluid, comprising the following steps:

[0031] Step 1: Put 25 parts of diesel oil into a high stirring cup, add 2 parts of compound emulsifier, and stir at high speed for 10 minutes at a speed of 12000r / min.

[0032] Step 2: Add 4 parts of calcium chloride brine, and perform high-speed stirring for 10 minutes at a speed of 12000 r / min.

[0033] Step 3: Add 1.7 parts of calcium oxide powder, and perform high-speed stirring for 10 minutes at a speed of 12000 r / min.

[0034] Step 4: Add 1.5 parts of organic bentonite, and perform high-speed stirring for 20 minutes at a ...

Embodiment 2

[0038] As the best implementation mode of the present invention, a preparation method of diesel-based drilling fluid with high resistance to salt water pollution is configured according to the same steps as in Example 1, and the difference from Example 1 is that the addition amount of the composite emulsifier is changed to 1.5 parts.

Embodiment 3

[0040] As the best implementation mode of the present invention, a preparation method of diesel-based drilling fluid with high resistance to salt water pollution is configured according to the same steps as in Example 1, and the difference from Example 1 is that the amount of calcium chloride brine is changed to 3.5 parts .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com