Method for regulating and controlling performance of barite-weighted high-density water-based drilling fluid

A water-based drilling fluid and barite technology, applied in the field of drilling fluid, can solve the problems of poor wall-building properties, good wall-building properties, poor rheological properties, and difficulty in coordination and unification, and achieve high-temperature and high-pressure low filtration loss and easy rheological properties. Control, low fluid loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

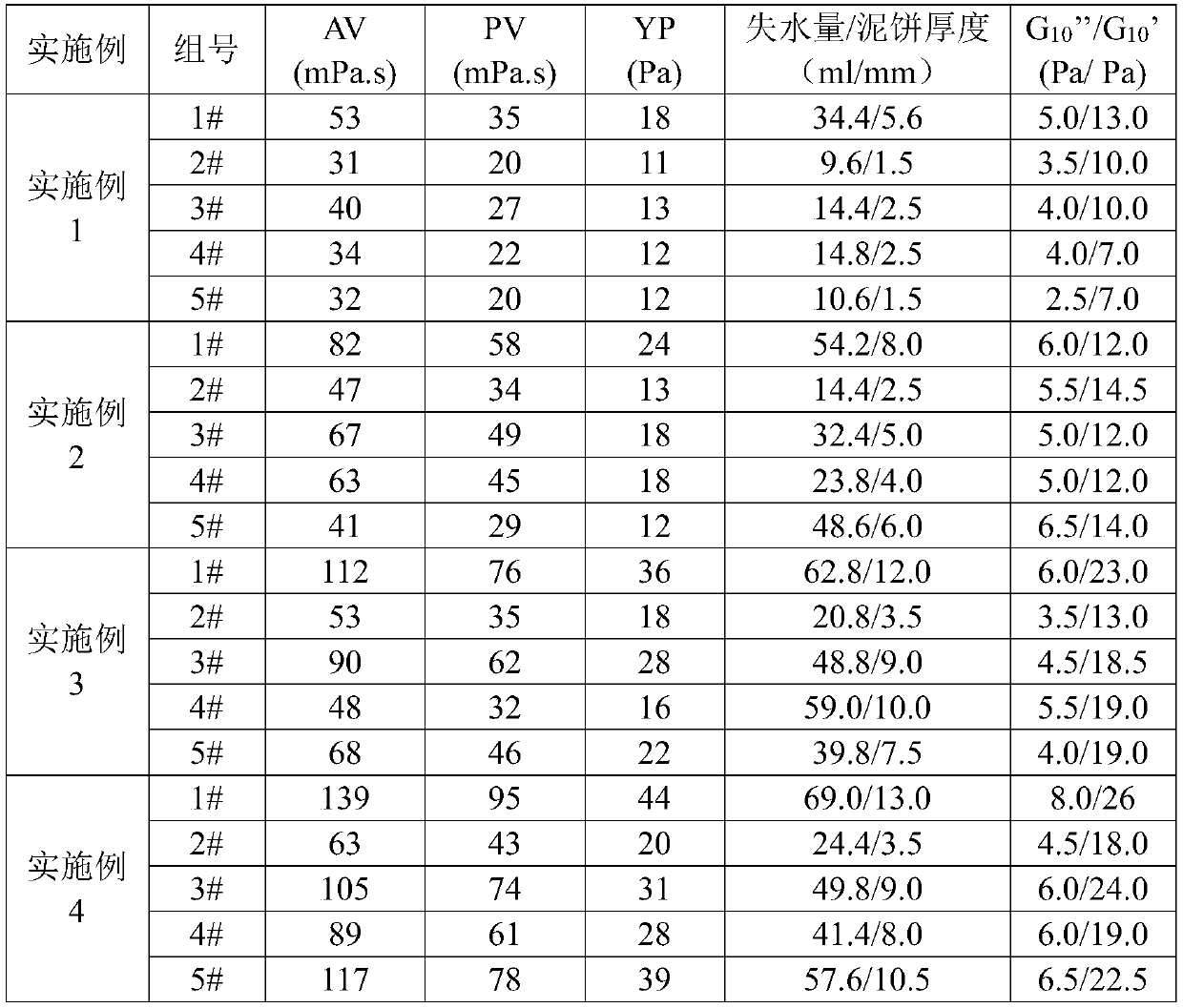

Embodiment 1

[0031] Sieve the barite powder with a grading sieve, collect the barite powder that passes through different apertures, and then compound the screened barite with barite of different particle sizes. The barite compounding method is shown in Table 1 :

[0032] Table 1

[0033] serial number Compound barite composition Proportion distribution of compound barite 1# 0.89μm barite 100% 2# 0.89μm barite: API barite 1:4 3# 0.89μm barite: API barite 3:7 4# 0.89μm barite: 44μm~63μm barite 1:4 5# 0.89μm barite: 44μm~63μm barite 3:7

[0034] The experimental drilling fluid base slurry is composed of 5% sodium bentonite slurry, 0.3% potassium polyacrylate, 5% sulfonated phenolic resin, 5% sulfonated lignite resin, 5% sulfonated lignite, 30% NaCl and 1% asbestos.

[0035] The preparation method of described experimental drilling fluid comprises the following steps:

[0036] (1) Water and bentonite are mixed and reacted under stirring co...

Embodiment 2

[0042] According to the method of Example 1, the only difference is that the experimental drilling fluid density increased to 1.80g / cm 3 .

Embodiment 3

[0044] According to the method of Example 1, the only difference is that the experimental drilling fluid density increased to 2.00g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com