Preparation process of solid glue moisturizing type release paper

A preparation process and technology of release paper, applied in the field of release paper, can solve the problems of inability to effectively maintain such strict environmental requirements, reduce the viscosity of viscous materials with peeling degree, affect the performance of release paper, etc., so as to improve environmental applicability, The effect of improving stability and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

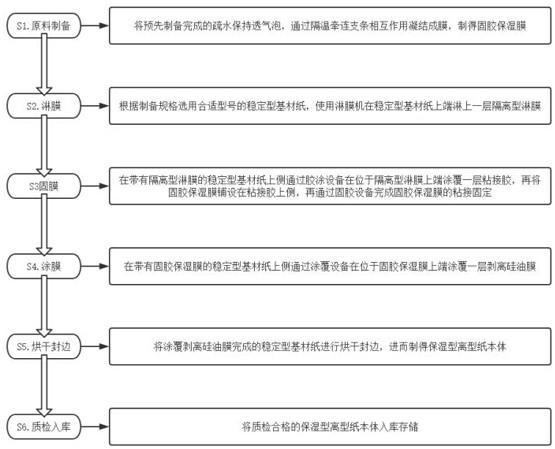

[0067] see figure 1 , image 3 , Figure 5 , Figure 6 and Figure 10 , a preparation process of glue-fixing and moisturizing type release paper, comprising the steps of:

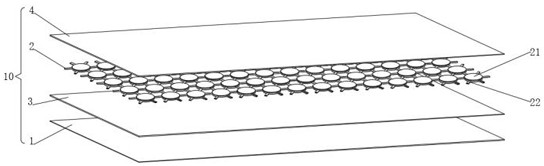

[0068] S1. Raw material preparation: The pre-prepared hydrophobic air-permeable air cells 21 are condensed into a film through the interaction of the temperature-insulating implicated branches 22, and the glue-fixed moisturizing film 2 is obtained;

[0069] S2. Coating: Select a suitable type of stable substrate paper 1 according to the preparation specifications, and use a laminating machine to coat a layer of isolation coating 3 on the upper end of the stable substrate paper 1;

[0070] S3 solid film: apply a layer of adhesive glue on the upper side of the stable base paper 1 with the isolation type coating 3 through glue coating equipment, and then lay the solid glue moisturizing film 2 on the top of the isolation type coating 3 Bond the upper side of the glue, and then complete the bonding and fixi...

Embodiment 2

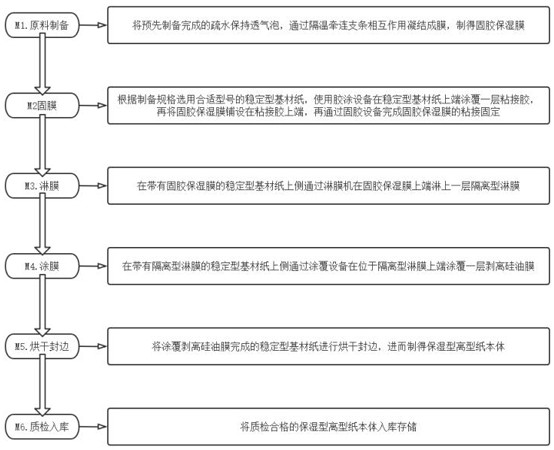

[0084] see figure 2 , Figure 4-6 and Figure 10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to figure 2 and Figure 4 , a preparation process of glue-fixing and moisturizing type release paper, comprising the steps of:

[0085] M1. Raw material preparation: The pre-prepared hydrophobic air-retaining air cells 21 are condensed into a film through the interaction of the temperature-insulating implicated branches 22, and the glue-fixed moisturizing film 2 is obtained;

[0086] M2 solid film: select a suitable type of stable base paper 1 according to the preparation specifications, use glue coating equipment to coat a layer of adhesive on the upper end of the stable base paper 1, and then lay the solid glue moisturizing ...

Embodiment 3

[0101] see Figure 6-9 and Figure 11 , wherein the same or corresponding components as those in Embodiment 1 or 2 use the corresponding reference numerals as in Embodiment 1 or 2, and for the sake of simplicity, only the differences from Embodiment 1 or 2 are described below. The difference between this embodiment 3 and embodiment 1 or 2 is:

[0102] see Figure 6 and Figure 7 The hydrophobic air-retaining bubble 21 is provided with a temperature-sensing retaining component 6 matched with uniform temperature condensation hydrophobic particles 2102. The temperature-sensing maintaining component 6 includes a star-shaped temperature-conducting support 601, and the hydrophobic retaining air-permeable bubble 21 is fixedly connected in the center Star-shaped temperature-conducting support 601, the outer end of the star-shaped temperature-conducting support 601 is fixedly connected with a uniform temperature condensation ring 602, and the outer end of the uniform temperature con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com