Soft coal seam roof directional drilling hydraulic fracturing anti-reflection device and application method

A soft coal seam, hydraulic fracturing technology, applied in safety devices, earthwork drilling, gas discharge, etc., can solve the problems of rapid gas flow decay, hole collapse, fragmentation, etc., so as to reduce the difficulty of engineering construction and improve the fracturing effect. , The effect of solving the sealing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

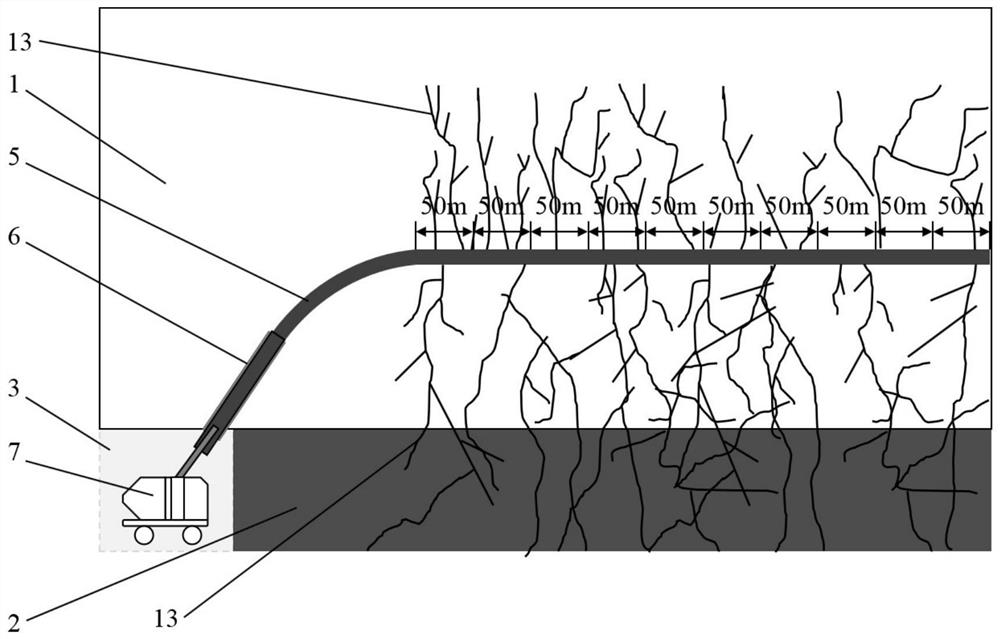

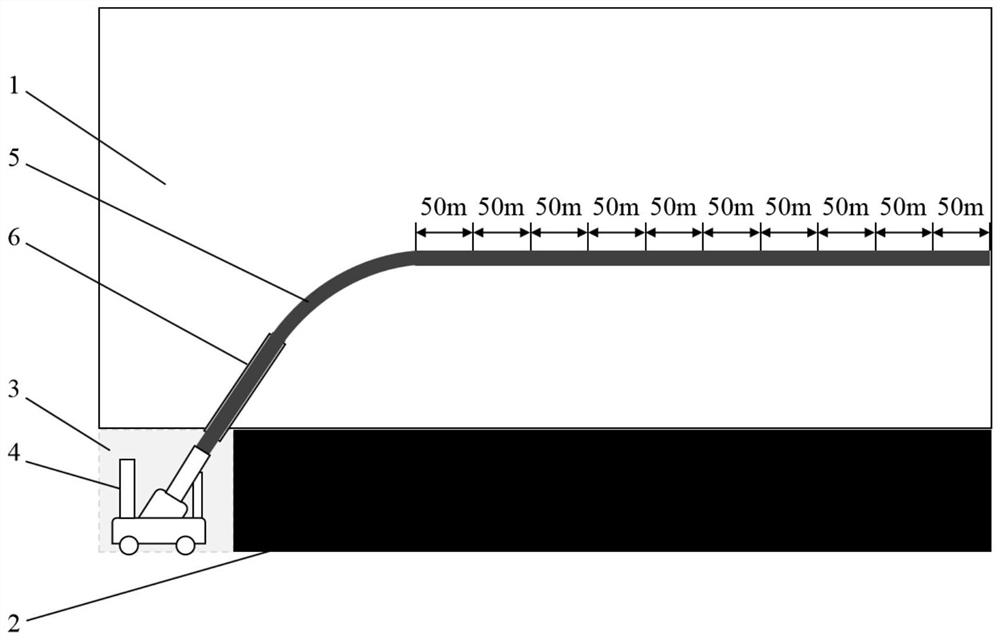

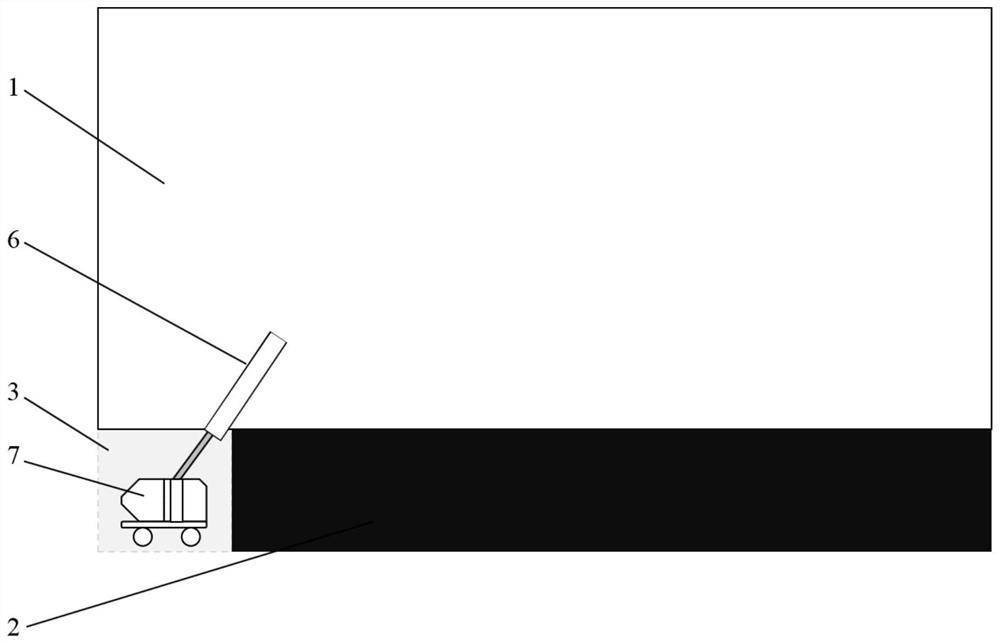

[0030] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0031] combine Figure 1-4 As shown, a hydraulic fracturing anti-permeability device for directional drilling on the roof of a soft coal seam includes a directional drilling rig 4, a grouting pump 7, a high-pressure oil pipe 8, a high-pressure oil pipe plugging device 9, a front packer 10, a rear end seal The separator 11 and the interceptor 12, through hydraulic sand fracturing in the roof rock layer 1, expand the crack 13 into the soft coal seam 2, enhance the air permeability of the soft coal seam 2, and achieve the purpose of releasing ground stress and strengthening gas drainage , and at the same time, the reliability of the construction process can be improved through staged fracturing technology.

[0032] A directional drilling hydraulic fracturing anti-permeability device and application method on the roof of a soft coal seam, the characteristics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com