Self-tapping expansion knotting heat-bridge-breaking anchor bolt for heat preservation system and installation method

A technology for building thermal insulation and heat insulation, applied in the field of building thermal insulation, can solve problems such as unsuitable construction techniques for external wall thermal insulation systems, and achieve reliable anchoring effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

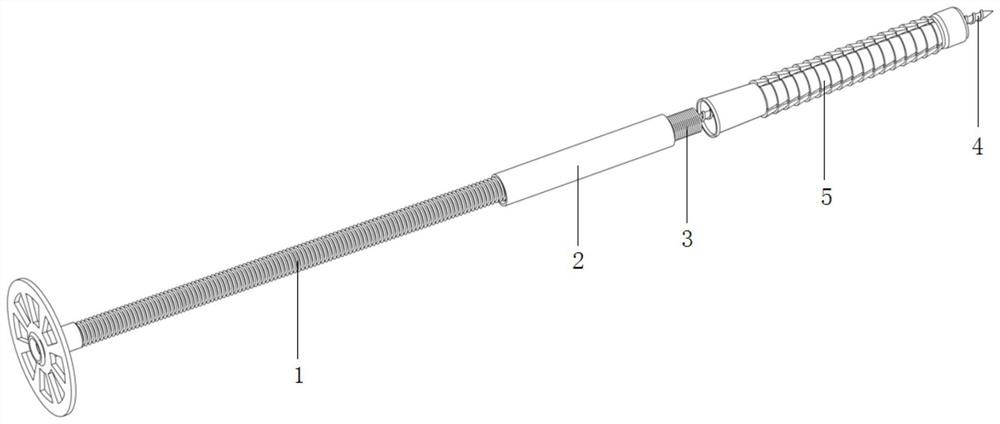

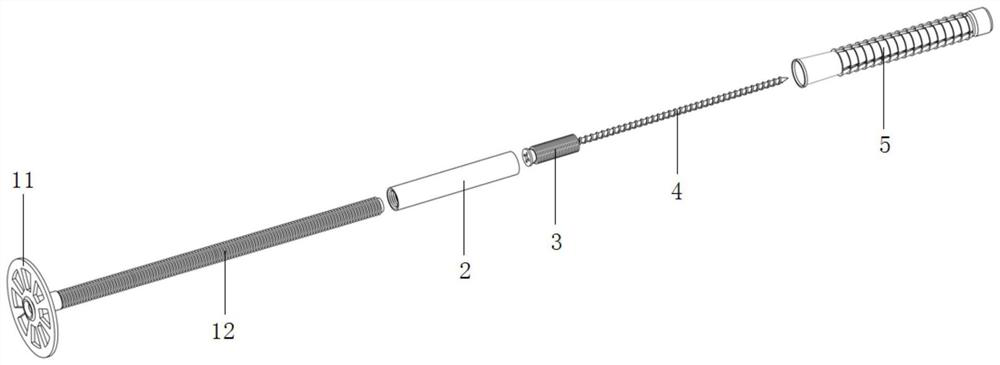

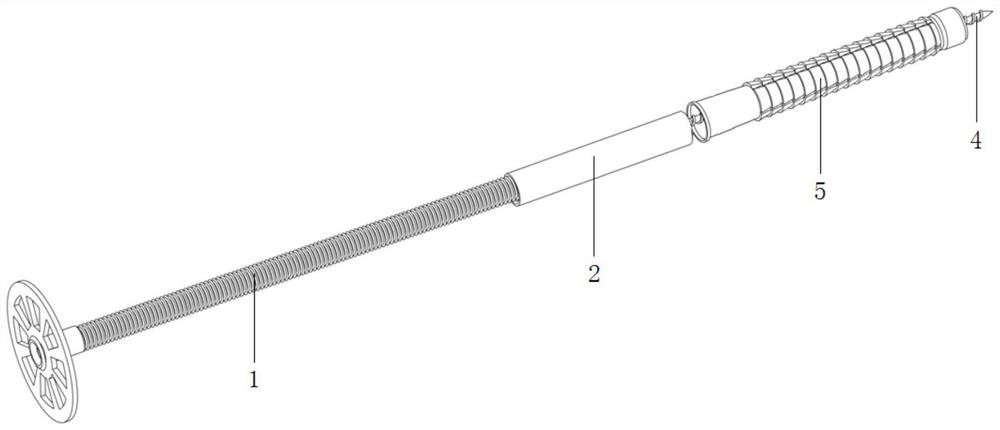

[0034] Such as Figure 1-9 As shown, a self-tapping expansion knotted thermal break bridge anchor bolt for a building thermal insulation system includes a thermal break bridge bolt 1, an anchor kit 5 and an internal screw tube 2 coaxially fixed with a self-tapping screw 4 at one end; The heat-breaking bridge bolt 1 is composed of an anchor disc 11 and a screw rod 12. The anchor disc 11 is coaxially fixed at one end of the screw rod 12, and an external thread is provided on the outer surface of the screw rod 12; There are internal threads; the anchoring set 5 is set on the screw end of the self-tapping screw 4, and the screw end of the self-tapping screw 4 is expanded and knotted with the anchoring set 5; the screw 12 of the heat-breaking bridge bolt 1 and the internal screw The pipe 2 is screwed and tightly fitted.

[0035] The nut ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap