Dehumidifying and dust-prevention device of generator set winding

A technology for generating sets and dust-proof devices, applied in the directions of using liquid separation agent, gas treatment, membrane technology, etc., can solve the problems of increasing air humidity, large bubble volume, and reducing bubbles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical content of the present invention, specific embodiments are provided below, and the present invention is further described in conjunction with the accompanying drawings.

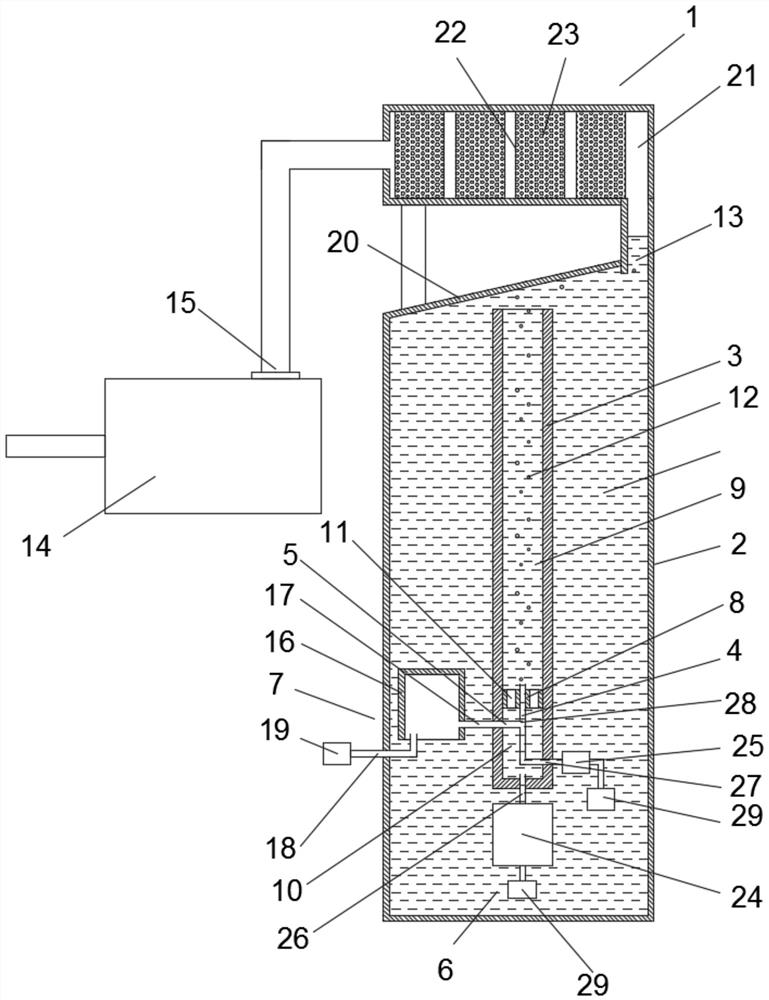

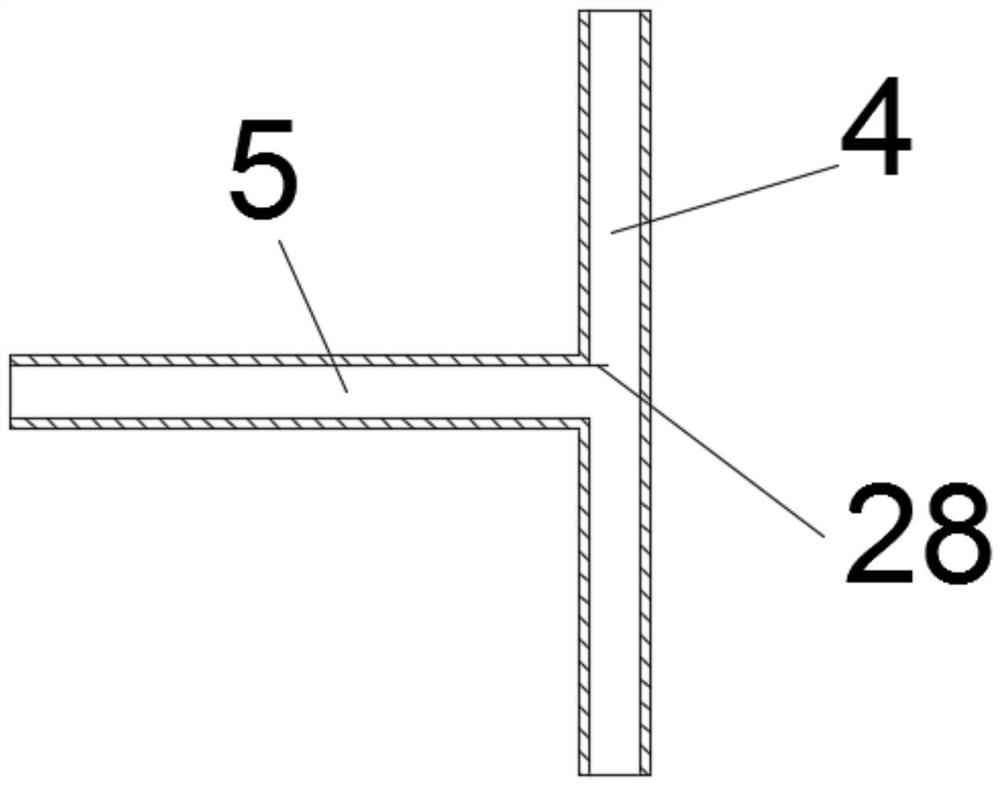

[0019] see Figure 1~2 , a dehumidification and dust-proof device for generator set windings, comprising a drying tank 1, a water tank 2, a water pipe 3, a first needle tube 4, a second needle tube 5, a water pumping device 6 and an air supply device 7, and the water tank 2 is equipped with Cooling water, the water pipe 3 is located in the water tank 2, the two ends of the water pipe 3 are provided with openings, the water pipe 3 is provided with a water pipe 3 into the first cavity 9 and the second cavity 10 The isolation plate 8 is provided with a plurality of through holes 11 communicating with the first cavity 9 and the second cavity 10, and the first needle tube 4 passes through the middle of the isolation plate 8 to communicate with the first cavity 9 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com