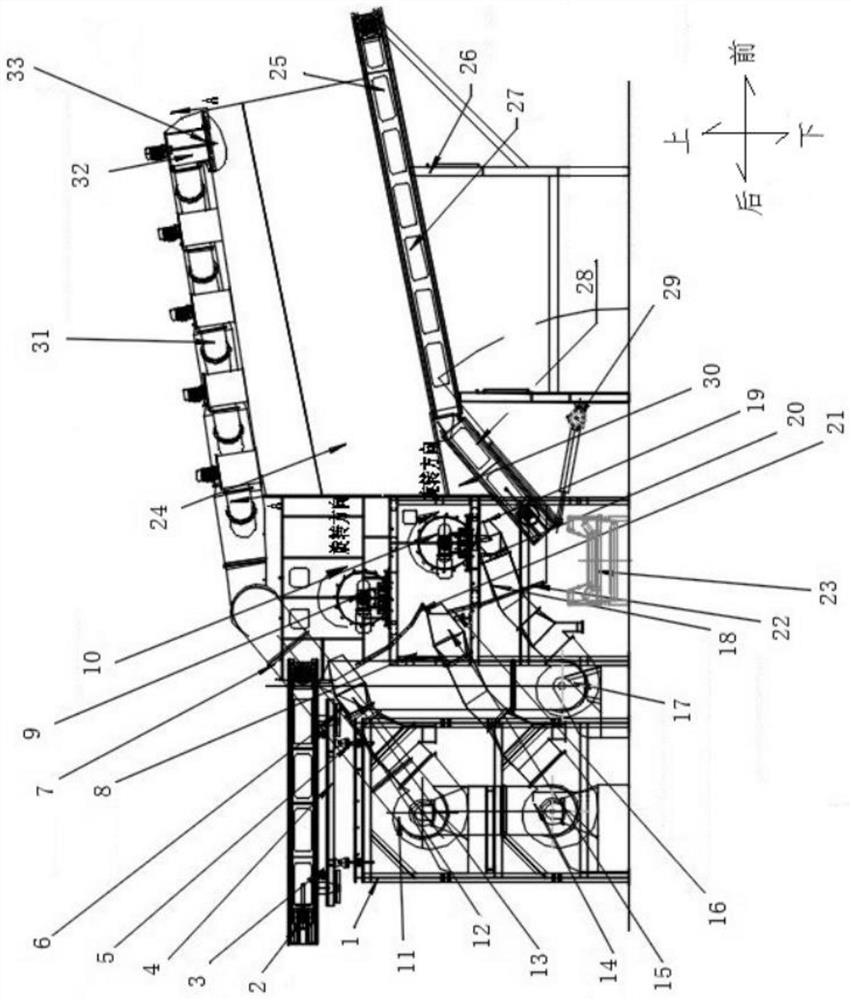

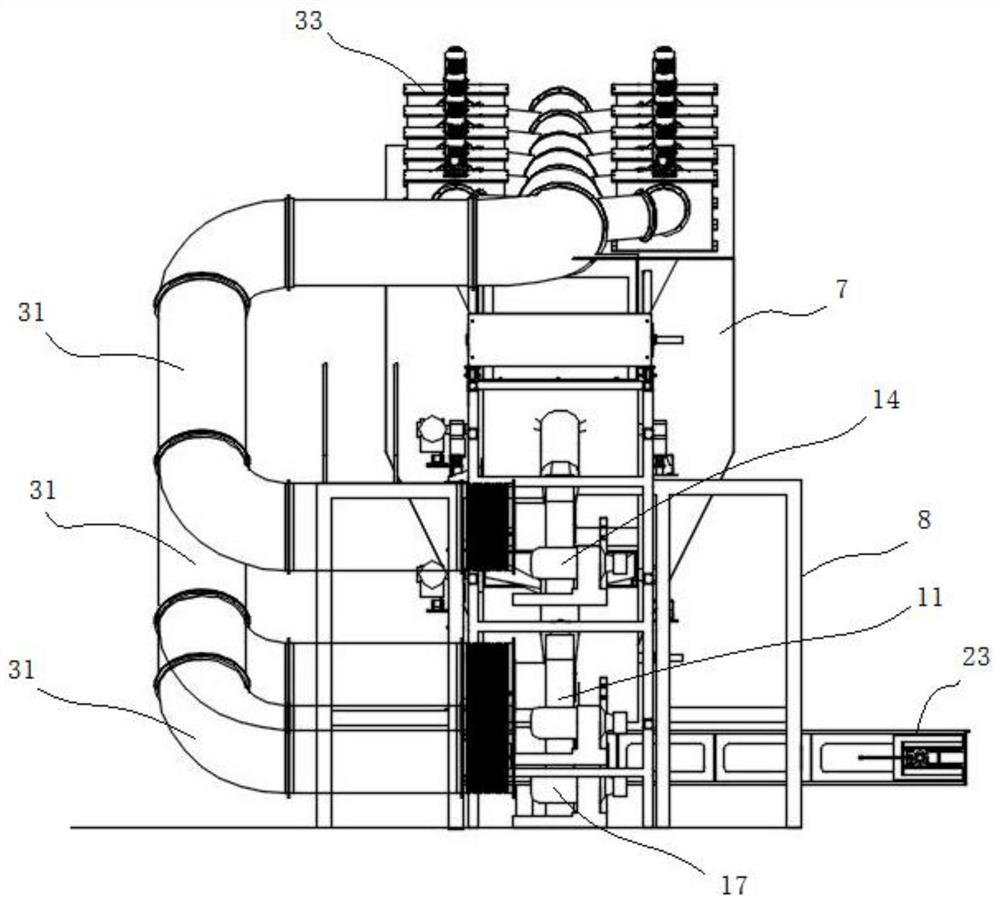

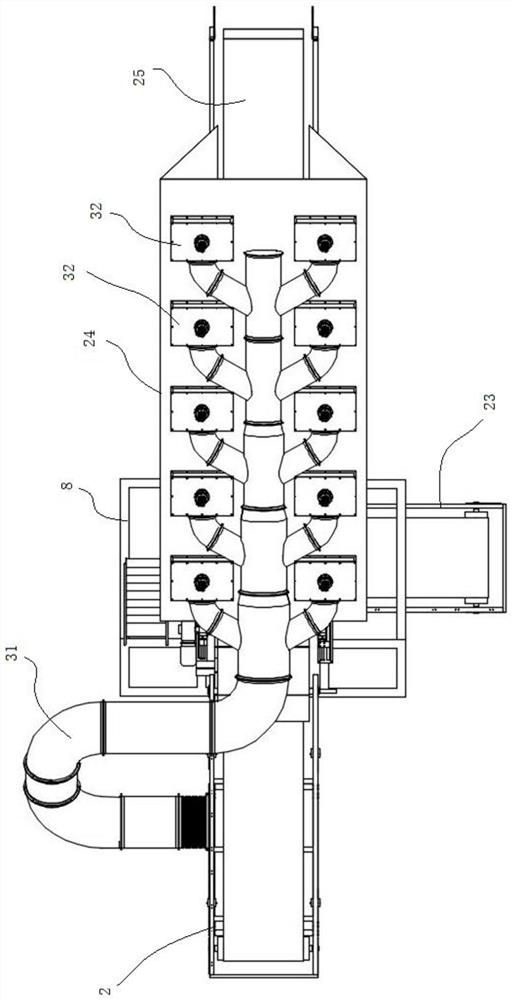

High-efficiency comprehensive winnowing equipment with functions of raising dust control and separation of objects with approximate specific gravity

A kind of winnowing equipment and technology of approaching objects, which is applied in the direction of solid separation, separation method, and dispersed particle separation, etc. It can solve the problems of inability to guarantee the purity of first-grade winnowing products, increase equipment investment, and poor economy, and achieve high-efficiency synthesis Air selection, improve the quality of air selection, and reduce the effect of impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the process of realizing this application, the inventor found that even if some large winnowing equipment itself integrates two-stage, three-stage or even multi-stage winnowing, it is only for a single one of the two types of products of the first-grade winnowing Repeated multi-stage purification and separation of materials, so that the purity of another first-stage air separation product without repeated air separation or repeated separation cannot be guaranteed. For example, for the light and heavy objects selected by the first-stage wind selection, the multi-stage air separation is to perform multi-stage purification and separation of the light objects, and the purity of the heavy objects selected by the other separation cannot be guaranteed.

[0041] In addition, the inventor also found that in other prior art, the two-stage rotary hubs are arranged front and back, and the second-stage rotary hub cannot accept the medium-heavy objects transported by the first-stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com