Beverage bottle label separating method and beverage bottle label separating machine

A beverage bottle and label technology, which is applied in the field of beverage bottle label detachment method and beverage bottle label detachment machine, can solve the problem that the label is difficult to remove, and achieve the effect of improving the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

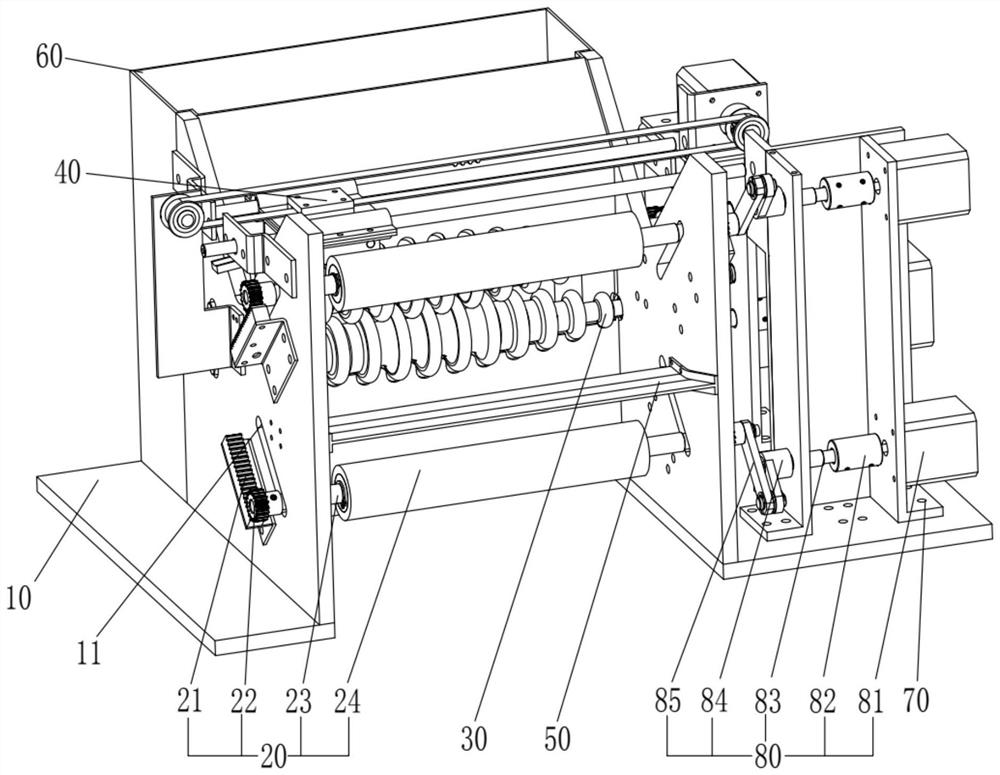

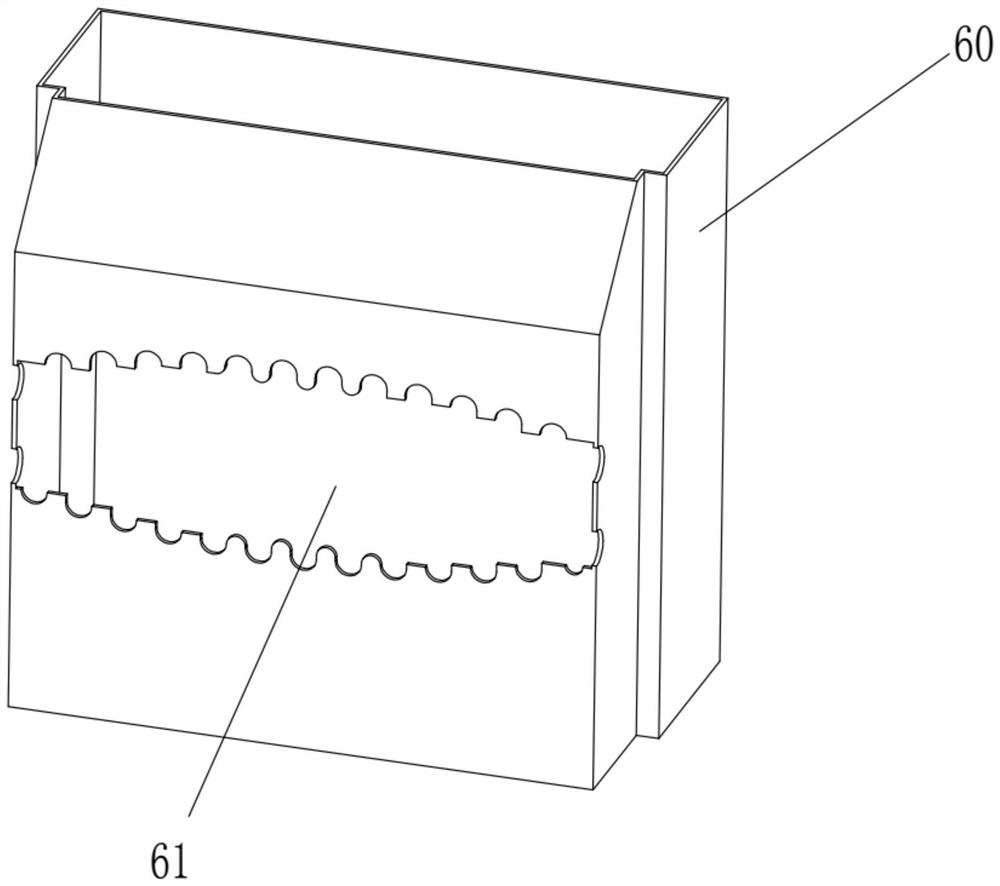

[0078] The invention discloses a beverage bottle label detaching machine, please refer to Figure 1 to Figure 4 . The beverage bottle label detaching machine includes: a frame 10, a movable roller assembly 20, a fixed roller assembly 30 and a cutting assembly 40; wherein, the frame 10 is a symmetrical structure, and two opposite sides of the frame 10 are located Symmetrically equipped with moving grooves; combined with figure 1 Description, the left side of the rack 10 is provided with two through moving grooves 11, the two moving grooves 11 are arranged in a cross (but not intersecting), and the two moving grooves 11 are arranged symmetrically with each other, and the rack 10 The right side is symmetrical with the left side, and the right side is also provided with the same moving groove 11 as the left side.

[0079] Further, the movable roller assemblies 20 are symmetrically arranged in the frame 10, and are gathered or separated through the moving grooves 11; that is, bot...

Embodiment 2

[0100] see Figure 7 , Based on the above-mentioned beverage bottle label detachment machine, the present invention also provides a beverage bottle label detachment method, which specifically includes the steps:

[0101] S100. Drive the movable roller assembly 20 to move along the moving groove 11 according to the size of the beverage bottle, so as to adjust the distance between the movable roller assemblies 20 and the distance between the movable roller assembly 20 and the fixed roller assembly 30, so that the The beverage bottle is clamped between the movable roller assembly 20 and the fixed roller assembly 30;

[0102] S200, driving the cutting assembly 40 to cut along the bottle body of the beverage bottle to separate the label from the beverage bottle;

[0103] S300 , the fixed roller assembly 30 is driven to rotate, and the label is pulled out from the beverage bottle through the frictional motion between the fixed roller assembly 30 and the label to complete the remova...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap