Regeneration equipment for adsorbing heavy metals in water by using complex resin and process thereof

A technology of resin adsorption and regeneration equipment, applied in the fields of adsorption water/sewage treatment, water pollutants, water/sewage treatment, etc., can solve the problem of waste of regenerated acid consumption and high acid concentration, and achieve saving acid consumption, high heavy metal concentration, The effect of saving the amount of cleaning water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

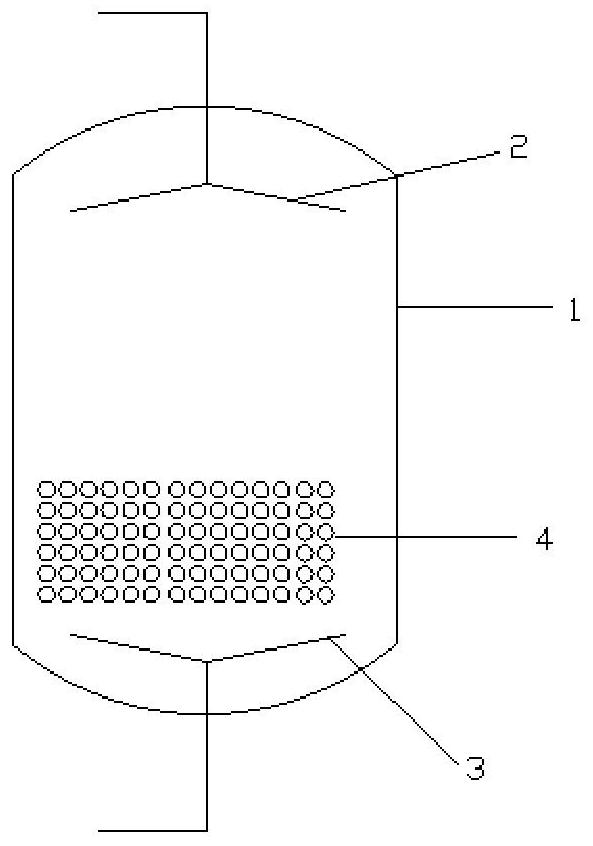

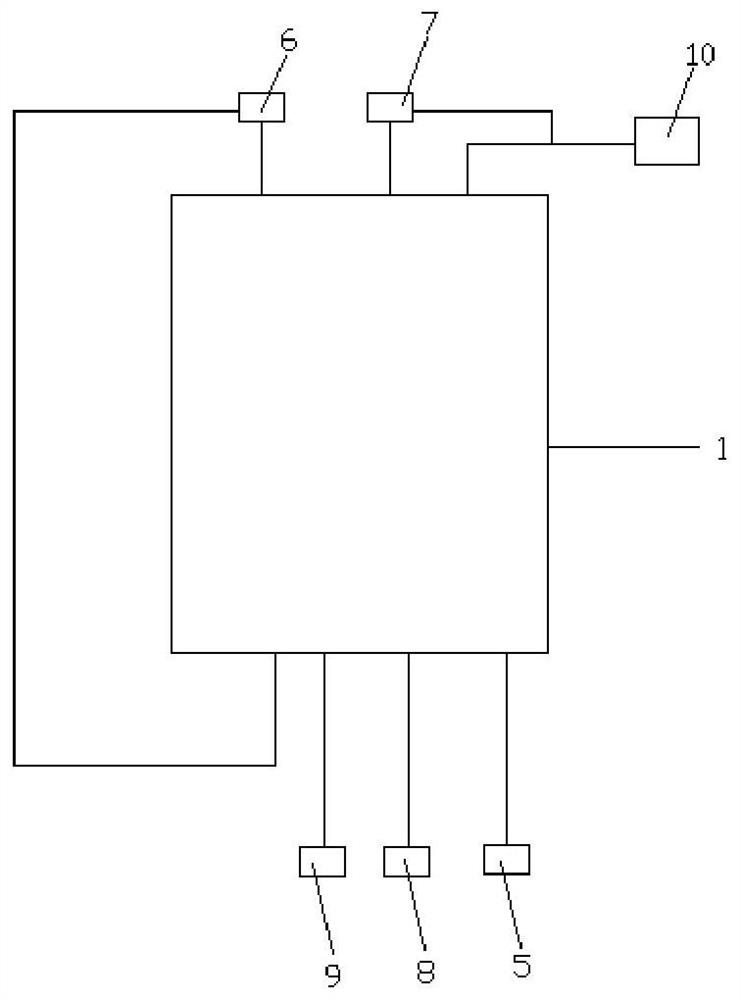

[0044] Such as Figure 1-2 As shown, a regeneration equipment for heavy metals in complex resin adsorption water, wherein, the equipment for complex resin adsorption heavy metals in water includes a resin tank 1, the upper end of the resin tank 1 is provided with an upper water distributor 2, and the resin tank 1 The lower end is provided with a lower water distributor 3, the top of the lower water distributor 3 is filled with a resin layer 4, the top of the resin tank 1 is respectively connected to the first acid tank 6 and the second acid tank 7 through pipelines, and the bottom of the resin tank 1 is passed through The pipelines are respectively connected to the regenerating return bucket 5, the alkali bucket 8 and the heavy metal recovery bucket 9.

Embodiment 2

[0046] A regeneration process for heavy metals in complexed resin adsorption water, wherein the regeneration process comprises the following steps:

[0047] Backwashing, draining, primary acid suction, primary acid discharge, secondary acid suction, secondary acid discharge, acid cleaning, alkali suction, alkaline cleaning and forward washing before produced water.

[0048] Wherein, the regeneration process is specifically:

[0049] S1. Backwashing: the water regenerated back into the water bucket 5 enters the bottom of the resin tank 1 through the pipeline, and the solid matter intercepted on the resin is washed from bottom to top;

[0050] S2. Drainage: the water in the resin tank 1 is forcibly drained or left to drain for 5-15 minutes through compressed air of 0.1-0.3Mpa;

[0051] S3. One-time acid absorption: Take the acid in the first acid tank 6, the acid absorption amount is 1 to 3 times the amount of resin used, the acid liquid flows in the resin tank 1 as up-in and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com