Moving bed filter

A technology of filter and filter material, which is applied in the direction of gravity filter, filter separation, loose filter material filter, etc. It can solve the problems of washing impact, affecting the filtering effect, and uneven distribution of water flow, so as to increase the probability of mutual friction, The effect of improving space utilization and improving washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

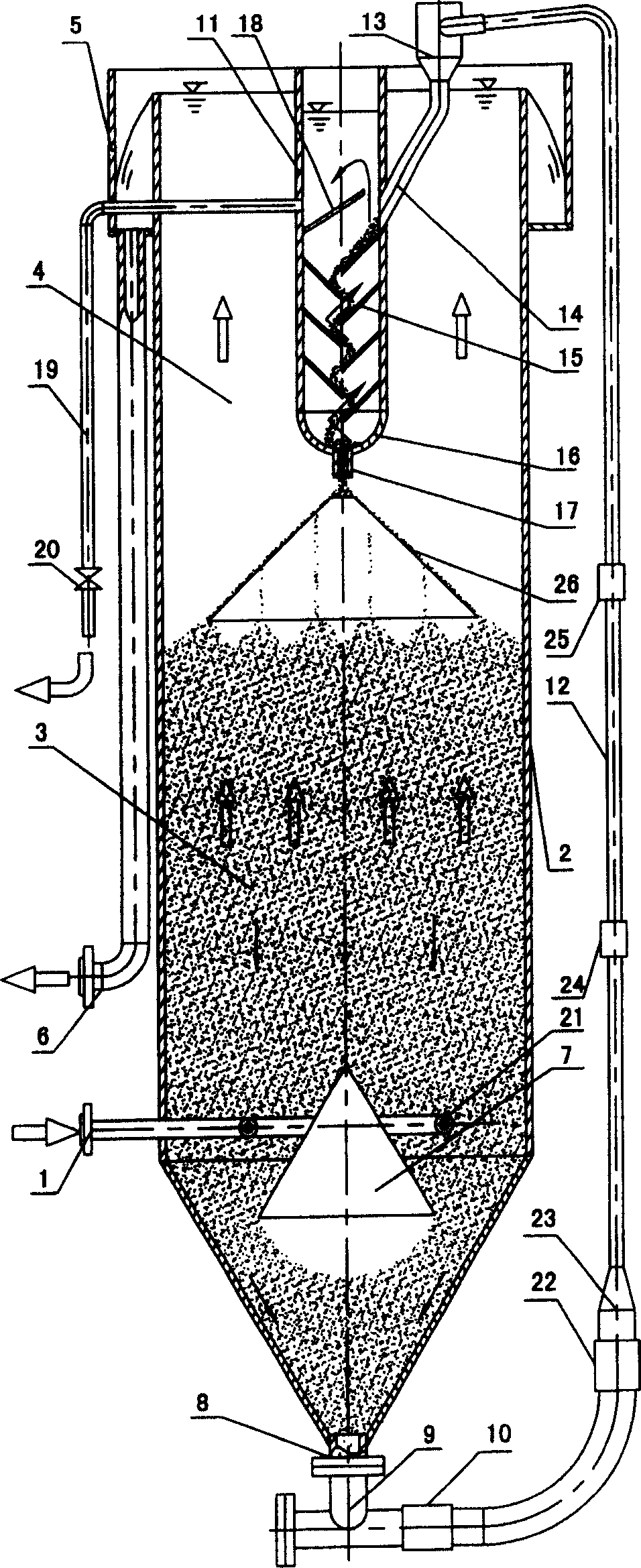

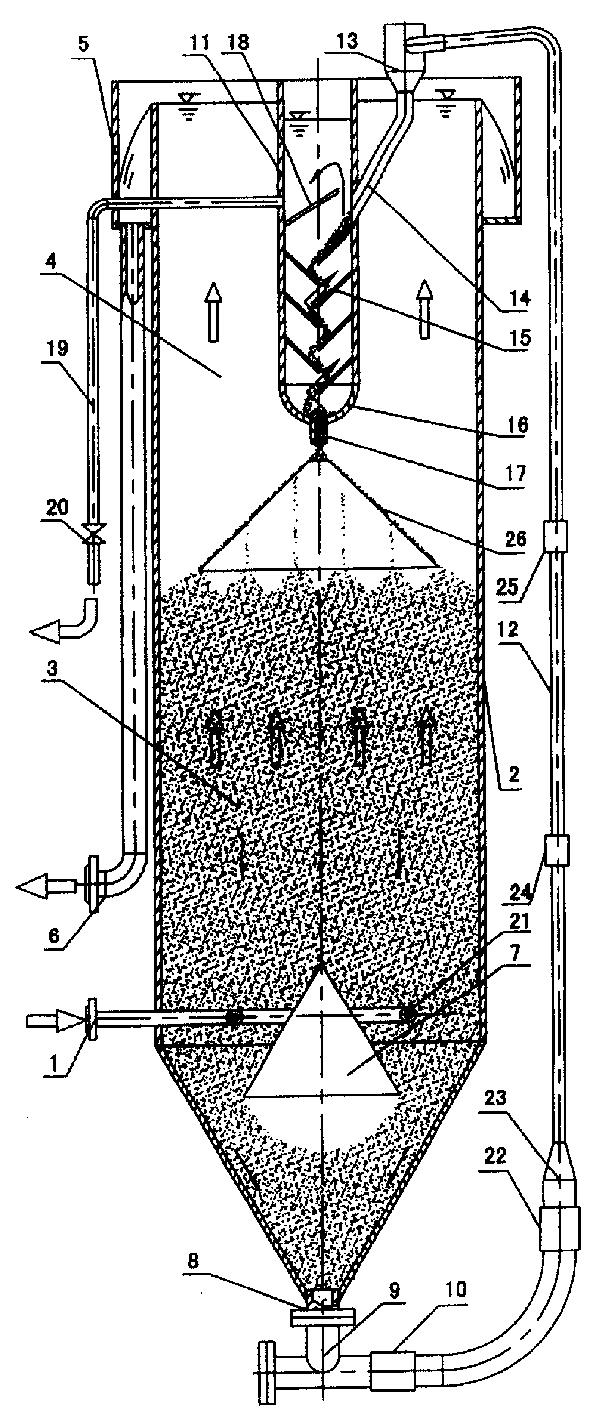

[0016] The structure and operation mode of the moving bed filter of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] The raw water enters the filter tank 2 from the water inlet 1, and after being distributed by the water distributor 21, it flows upward evenly and passes through the filter bed layer 3, and the suspended solids and other pollutants in the water are trapped in the filter material. The filtered clean water enters the clean water storage area 4 on the upper part of the filter tank, enters the overflow cofferdam 5 after overflowing, and is discharged through the water outlet 6 .

[0018] While filtering the raw water, the filter material of pollutants is trapped in the lower part of the filter tank 2, and under the action of gravity, it continuously moves downwards, passes through the rectifier 7, the filter material outlet 8, and then passes through the air distributor 10, 22, 24 and Under the action of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com