High-strength and high-toughness forklift steel with thickness specification of 10-60 mm and preparation method thereof

A high-strength, high-toughness technology, applied in the field of iron and steel smelting, can solve problems such as low product performance qualification rate, achieve the effect of improving material utilization, good economic and social benefits, and reducing alloy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

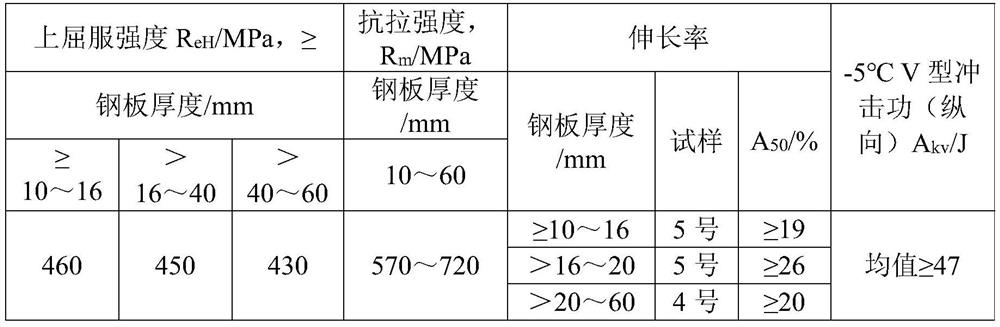

[0040] According to an embodiment of the present invention, a high-strength low-temperature-resistant forklift steel with a thickness of 10-60 mm and a preparation method thereof are provided. By weight percentage, forklift steel includes the following components: 0.16%≤C≤0.18%, 0.15%≤Si≤0.30%, 1.45%≤Mn≤1.55%, 0≤S≤0.010%, 0≤P≤0.018%, 0.025 %≤Nb≤0.045%, 0.030%≤V≤0.050%, 0.010%≤Ti≤0.020%, 0.015%≤Als≤0.055%, the rest is iron and unavoidable impurities, and Als is acid-soluble aluminum. The minimum value of impact toughness at a temperature of -5°C is ≥150J. The steel for forklifts has low cost, excellent low-temperature impact toughness, and excellent comprehensive properties such as product strength, elongation after fracture, and cold bending performance. And it adopts low C+Nb, V, Ti microalloying composition design to ensure that the steel plate has easy weldability.

[0041] The composition content control and function of the high-strength and low-temperature-resistant for...

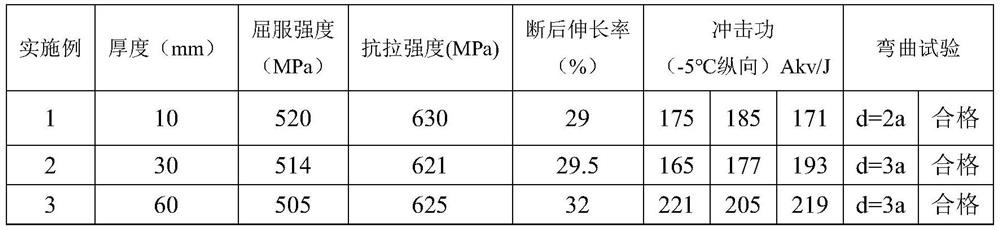

Embodiment 1

[0069] By weight percentage, forklift steel includes the following components: C: 0.165%, Si: 0.20%, Mn: 1.50%, P: 0.015%, S: 0.005%, Nb: 0.040%, V: 0.035%, Ti: 0.015% , Als: 0.025%, the balance is iron and unavoidable impurities.

[0070] A method for manufacturing steel for forklifts containing the above components, the production process includes the following steps:

[0071] 1) Pretreatment, hot metal desulfurization strictly implement the process regulations, the sulfur in the hot metal is controlled at 0.008%, the temperature is 1250 ℃, and the slag on the surface of the hot metal is removed after desulfurization.

[0072] 2) Smelting, the pretreated molten iron enters the converter for smelting, the slagging material is added 3 minutes before the end point, the final slag basicity is controlled at R=3.0, and the end point pressure gun time is 65s. Almanganese iron is used for deoxidation, and the amount of aluminum manganese iron added is 2.5kg / t. When the molten stee...

Embodiment 2

[0080] By weight percentage, forklift steel includes the following components: C: 0.166%, Si: 0.21%, Mn: 1.46%, P: 0.017%, S: 0.003%, Nb: 0.029%, V: 0.040%, Ti: 0.018% , Als: 0.026%, the balance is iron and unavoidable impurities.

[0081] A method for manufacturing steel for forklifts containing the above components, the production process includes the following steps:

[0082] 1) Pretreatment, hot metal desulfurization strictly implement the process regulations, the sulfur in the hot metal is controlled at 0.008%, the temperature is 1250 ℃, and the slag on the surface of the hot metal is removed after desulfurization.

[0083] 2) Smelting, the pretreated molten iron enters the converter for smelting, the slagging material is added 3 minutes before the end point, the final slag basicity is controlled at R=3.5, and the end point pressure gun time is 70s. Almanganese iron is used for deoxidation, and the amount of aluminum manganese iron added is 2.0kg / t. When the molten stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com