Ultrahigh-strength martensitic steel for automobile and rolling method

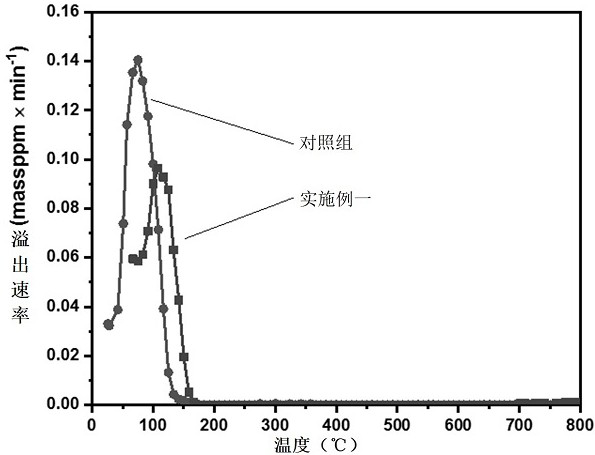

An ultra-high-strength, martensitic steel technology, applied in the field of steel alloy materials, can solve the problems of poor hydrogen embrittlement resistance and high energy consumption of cold-formed steel at production costs, achieve high tensile strength, improve hydrogen storage capacity, and plasticity Good shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

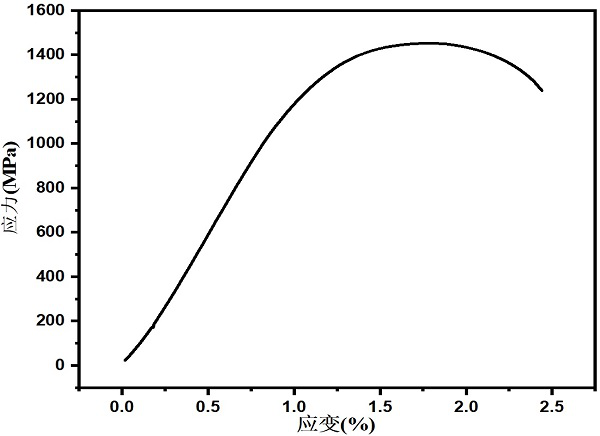

Embodiment 1

[0028] Embodiment 1, an ultra-high-strength martensitic steel for automobiles, which includes the following components by weight percentage: 0.21% of C, 0.21% of Si, 1.4% of Mn, 0.011% P, 0.0027% S, 0.04% Al, 0.14% Cr, 0.037% Ti, 0.0015% B, 0.017% V, 0.00181% Nb, 0.034% Ni, 0.14% Cu, The balance is Fe.

[0029] The rolling method of the ultra-high-strength martensitic steel for automobiles comprises the following steps:

[0030] Step 1: weighing according to the composition ratio of the above-mentioned ultra-high-strength martensitic steel for automobiles, and melting it into an austenitic billet.

[0031] Step 2, rolling the austenitic steel slab into a steel slab with a thickness of 20 mm, heating the steel slab to 1250° C. and keeping it warm for 2 hours, and then hot rolling to obtain a primary rolled steel plate with a thickness of 3.4 mm.

[0032] Step 3, the temperature of the primary rolled steel plate is lowered to 620°C, the cooling rate is 45°C / s, the temperature ...

Embodiment 2

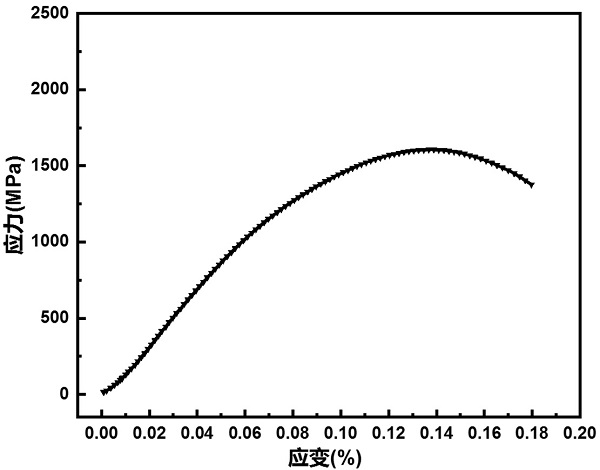

[0041] Embodiment 2, an ultra-high-strength martensitic steel for automobiles, the weight percentage of Cu element is 0.1%, and the weight percentage of other components is the same as that of Embodiment 1.

[0042] The rolling method of the ultra-high-strength martensitic steel for automobiles comprises the following steps:

[0043] Step 1: weighing according to the composition ratio of the above-mentioned ultra-high-strength martensitic steel for automobiles, and melting it into an austenitic billet.

[0044] Step 2, rolling the austenitic steel slab into a steel slab with a thickness of 20mm, heating the steel slab to 1200°C and keeping it warm for 1.5h, and then hot rolling to obtain a primary rolled steel plate with a thickness of 3.4mm.

[0045] Step 3, the temperature of the primary rolled steel plate is lowered to 650°C, the cooling rate is 40°C / s, the temperature is kept for 45 minutes, and then cooled to room temperature in the furnace; by controlling the cooling rat...

Embodiment 3

[0050] Embodiment 3, an ultra-high-strength martensitic steel for automobiles, the weight percentage of Cu element is 0.3%, and the weight percentage of other components is the same as that of Embodiment 1.

[0051] The rolling method of the ultra-high-strength martensitic steel for automobiles comprises the following steps:

[0052] Step 1: weighing according to the composition ratio of the above-mentioned ultra-high-strength martensitic steel for automobiles, and melting it into an austenitic billet.

[0053] Step 2, rolling the austenitic steel slab into a steel slab with a thickness of 20 mm, heating the steel slab to 1230° C. and keeping it warm for 1 hour, and then hot rolling to obtain a primary rolled steel plate with a thickness of 3.4 mm.

[0054] Step 3, the temperature of the primary rolled steel plate is lowered to 600°C, the cooling rate is 50°C / s, the temperature is kept for 50 minutes, and then cooled to room temperature in the furnace; by controlling the cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com