Groove grabbing replacement filling obstacle clearing method before SMW construction method pile construction of boulder-containing stratum

A technology of construction method piles and large blocks, which is applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems that construction method piles cannot be directly constructed, the construction site is narrow, and there are landslides, etc., and achieve good operation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

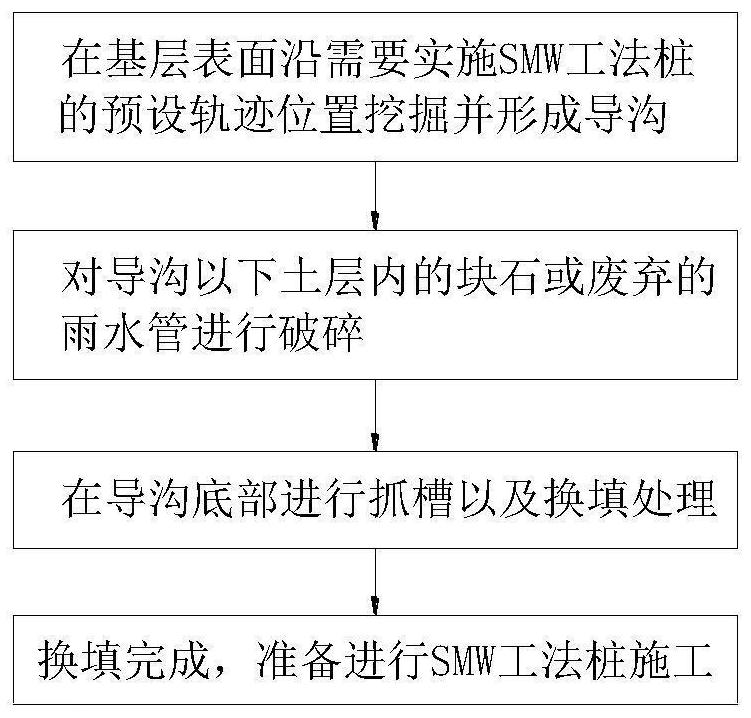

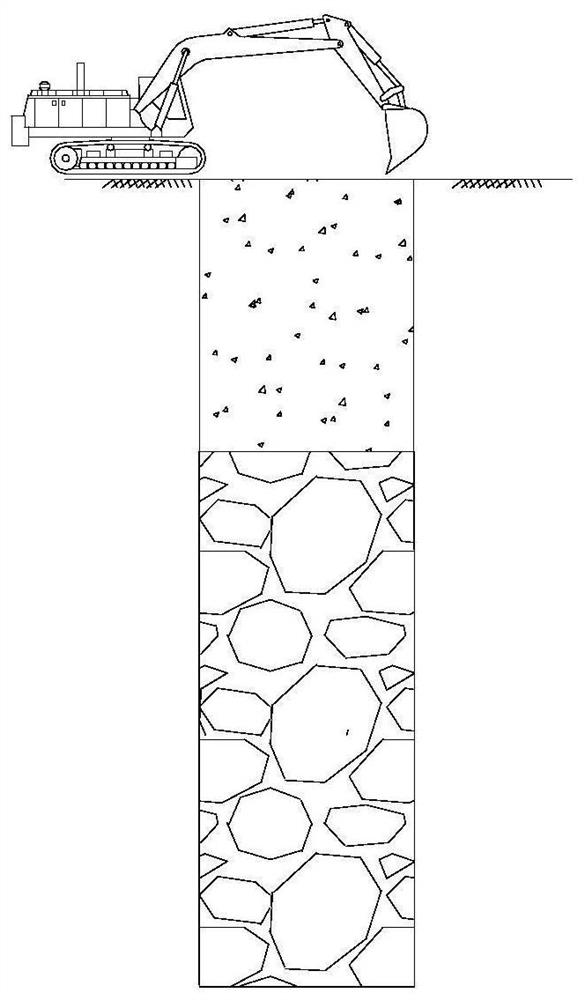

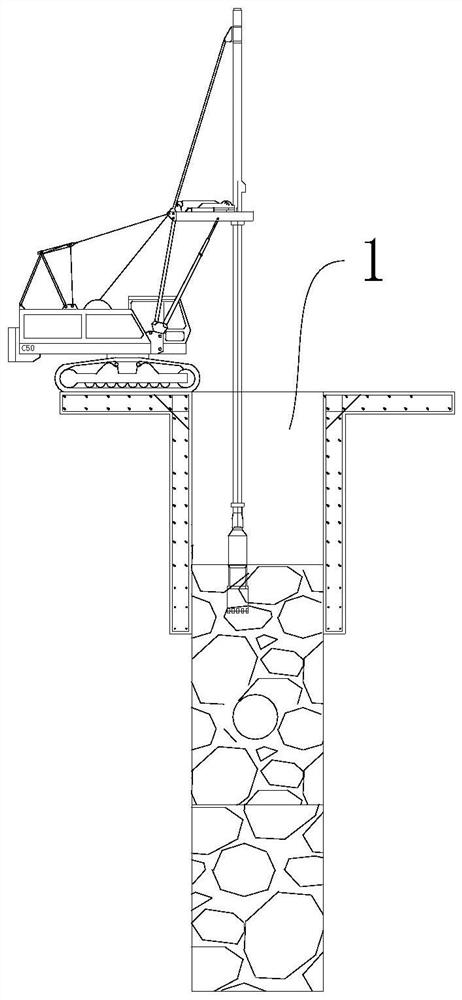

[0050] Please refer to Figure 1-Figure 4 , figure 1 It is a schematic flow diagram of the method in the embodiment of the present invention; figure 2 It is a working schematic diagram of the formation of the guide trench 1 in the embodiment of the present invention; image 3 It is a schematic diagram of the operation of the rotary drill to process rocks or abandoned pipelines in the embodiment of the present invention; Figure 4 It is a schematic diagram of the work of changing and filling the groove of the groove forming machine in the embodiment of the present invention.

[0051] The present embodiment provides the SMW engineering method pile construction method that contains large stone strata and grasps the groove and replaces and fills the obstacle removal method, and it comprises the following steps:

[0052] S1. Excavating and forming guide ditch 1 on the surface of the base layer along the preset trajectory position of the SMW construction method pile;

[0053] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com