Selective water plugging method for high-water-content oil well of bottom water reservoir

A bottom water reservoir, selective technology, applied in chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc., can solve the problems of difficult water shutoff and poor water shutoff effect in edge and bottom water reservoirs, and achieve Effects of increasing stability and strength, increasing oil resistance, and strengthening the effect of pressing the cone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The selective water shutoff method of the high water-cut oil well in the bottom water reservoir of the present invention is specifically as follows:

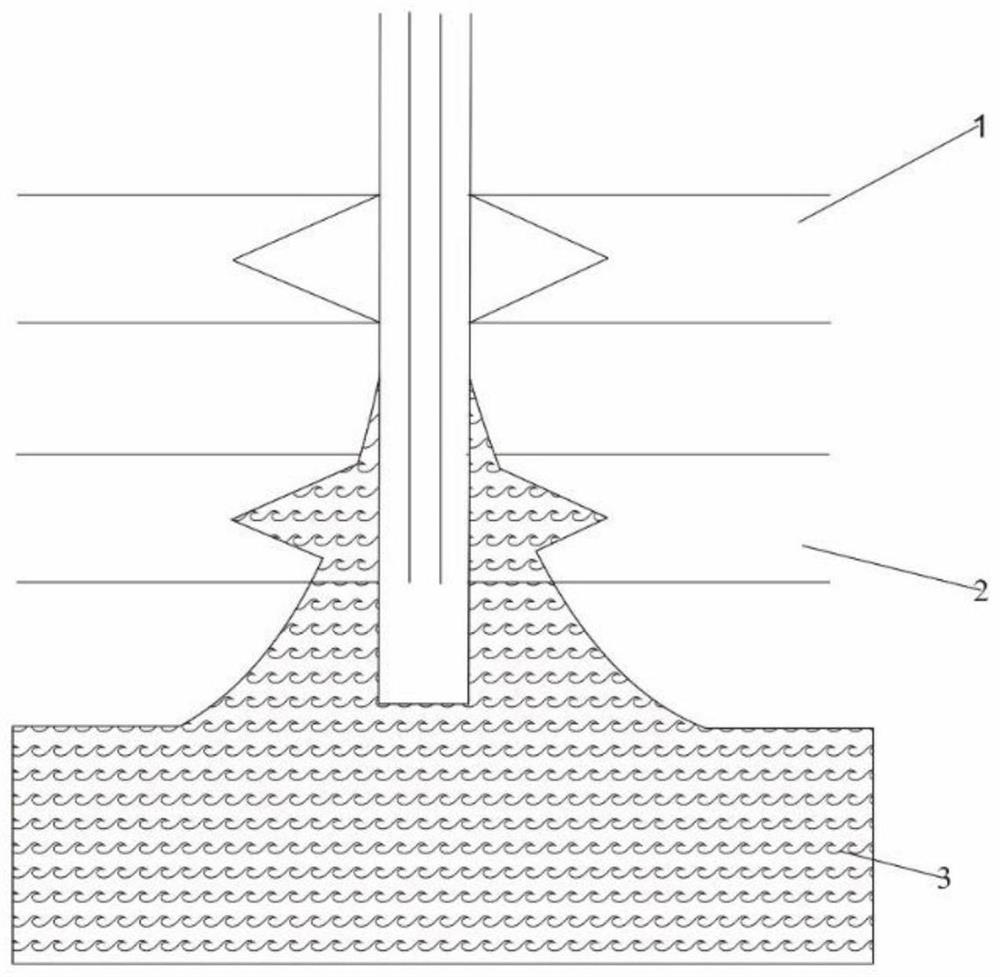

[0036] like figure 1 As shown, with long-term water injection production, the oil well enters the stage of high water cut, and the bottom water invades seriously, resulting in water cones and water flooding in the lower high permeability layer.

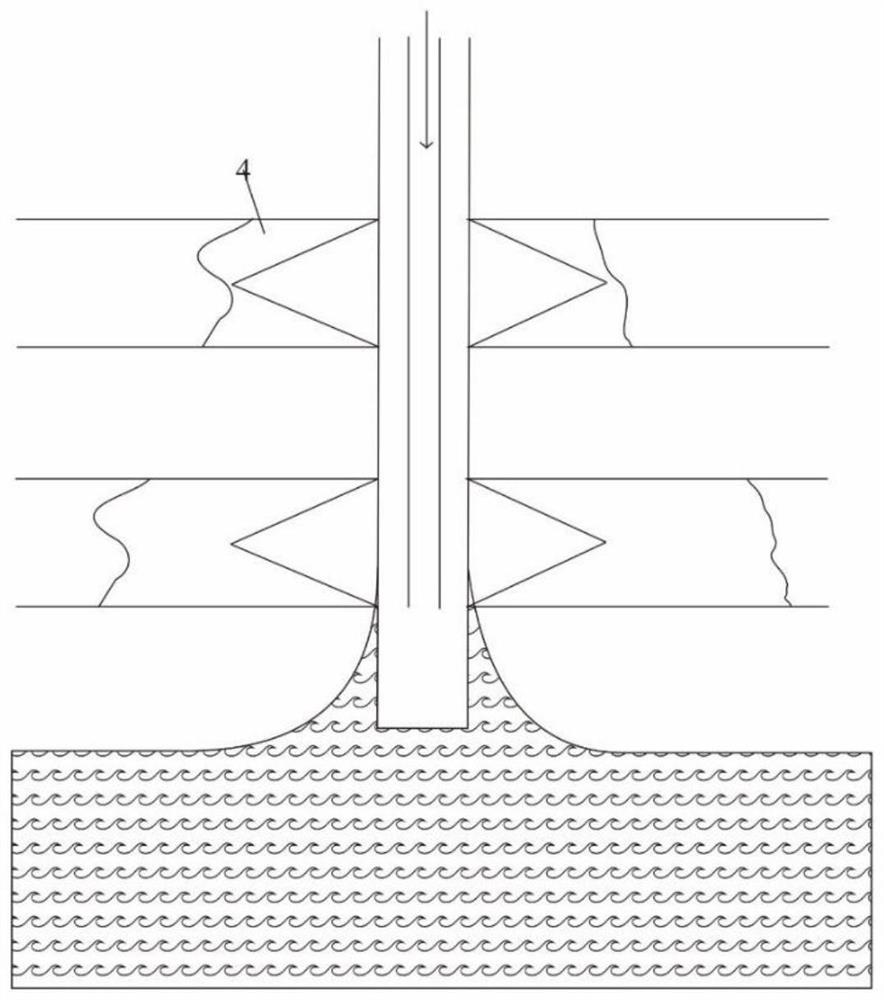

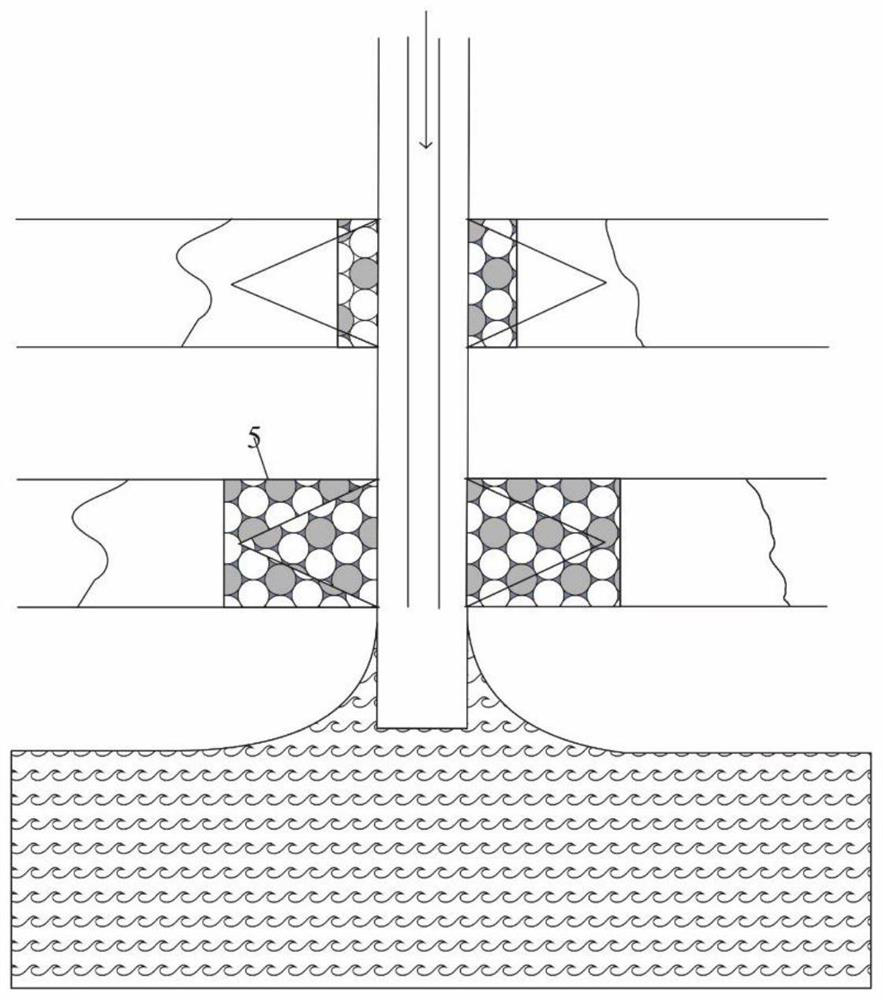

[0037] At this time, if figure 2 As shown, nitrogen is injected downhole at high speed and high pressure through tubing. At this time, nitrogen preferentially enters the hyperpermeable layer to increase the pressure of the hyperpermeable layer. The intrusion of nitrogen drives the intrusive water to the lower part to achieve the purpose of pressing down the water cone, which can be used for subsequent plugging. The entry of water agent creates conditions. Since nitrogen is injected into the formation at high speed and high pressure, some nitrogen enters the low-permeability la...

Embodiment 2

[0054] The water shutoff method of the present invention is applied to a specific high water cut oil well in a certain bottom water reservoir. The specific method is as follows:

[0055] S1. Inject nitrogen gas into the well at high speed and high pressure, so that nitrogen gas enters the high-permeability water-producing layer. The entry of nitrogen gas drives the intrusive water to the lower part, achieving the purpose of pressing down the water cone and providing conditions for subsequent operations. According to the research of the gel foam system, the optimal amount of nitrogen gas is twice the volume of the mixed solution injected in step S2, and the volume calculation formula of the mixed solution is: Q=πR 2 hφ, where R=10m, h=2m, φ=0.3. The amount of nitrogen injected uses the state equation PV=nRT to convert the ground volume, and the gas injection speed is controlled at 600-900m 3 / h, the gas injection pressure is higher than the formation pressure.

[0056] S2. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com