Deep groove ball bearing with split type retainer

A deep groove ball bearing and cage technology, applied in the field of bearings, can solve the problems of cage melting and cracking, unfavorable production and processing efficiency, and inconvenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

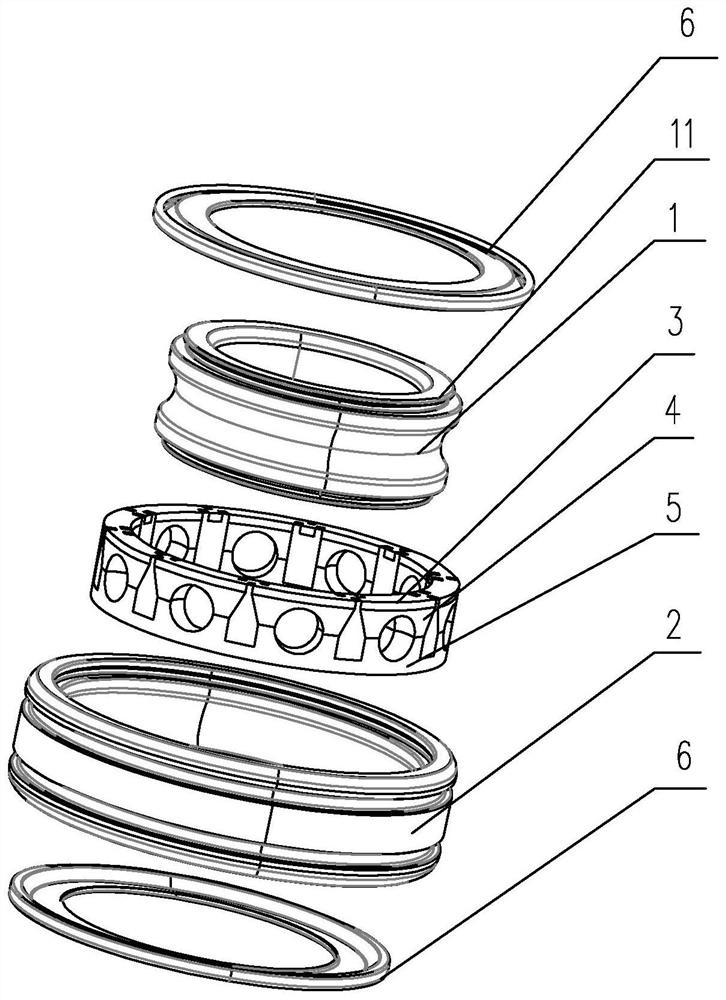

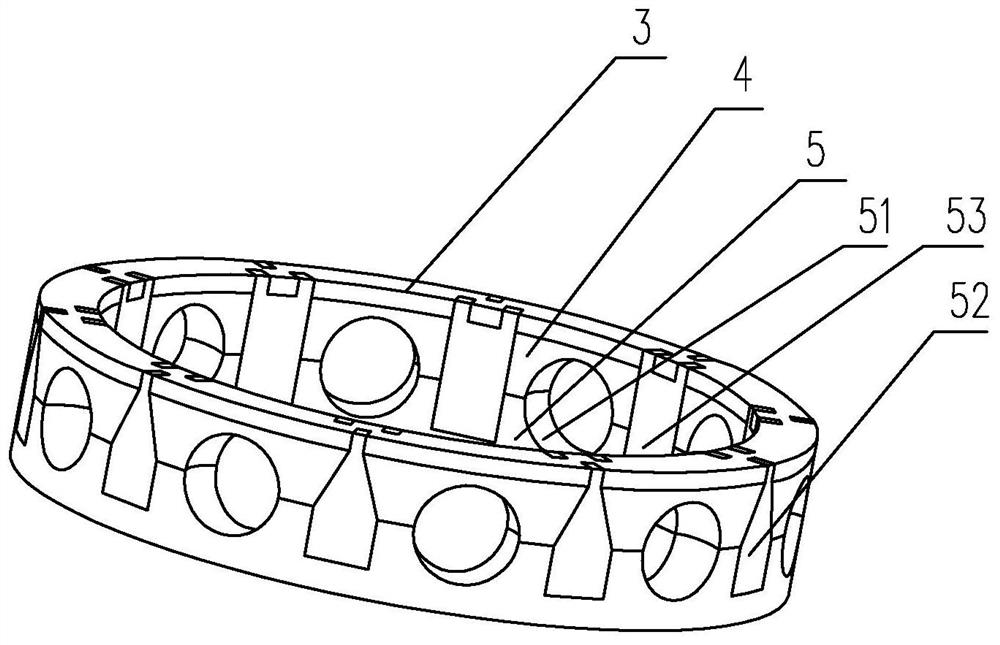

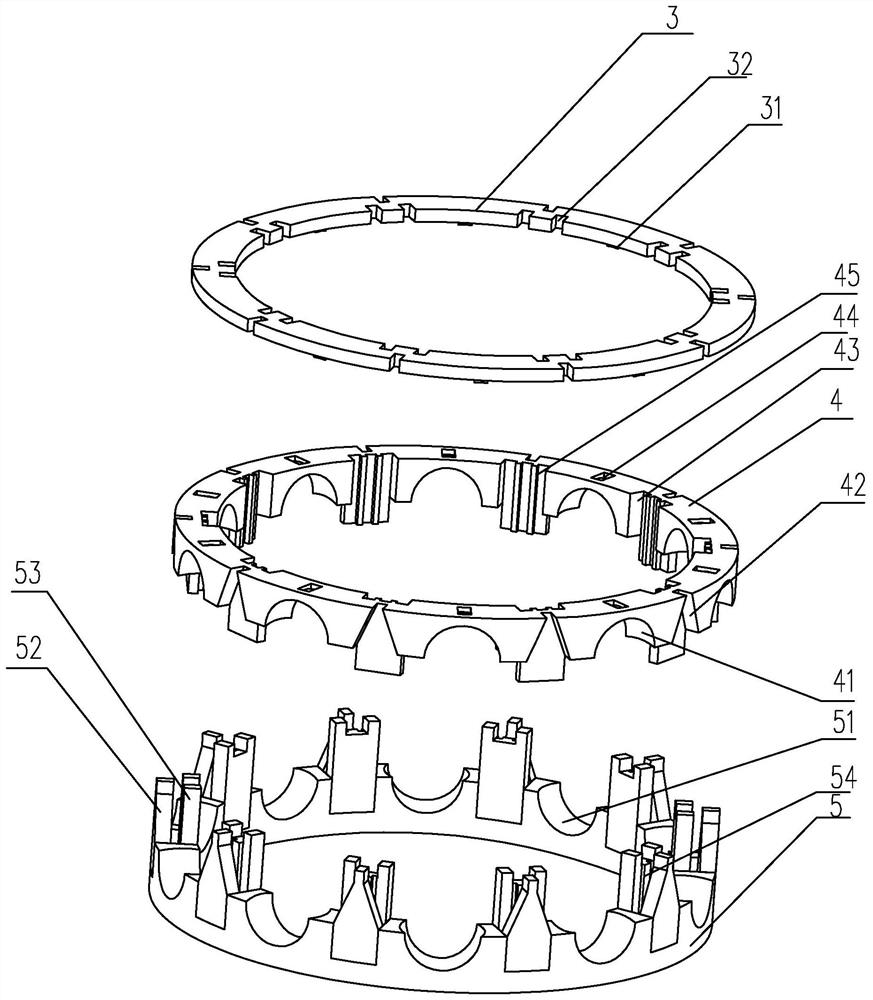

[0029] The first embodiment of the deep groove ball bearing with split cage of the present invention is as Figure 1 to Figure 3 As shown: including outer ring 2, inner ring 1, cage and steel balls, the cage is set between the outer ring 2 and the inner ring 1, and the cage is separated to form an upper frame body 3, a bearing frame 4 and The lower frame body 5 is provided with pockets 41 for accommodating steel balls at intervals on the carrier frame 4, and a connecting platform is arranged between adjacent pocket grooves 41 on the carrier frame 4, and a connecting platform is formed on the outer wall of the connecting platform. There is a first insertion groove 42, a second insertion groove 43 is provided on the inner wall of the connection platform, a connection groove 44 is opened on the bottom surface of the pocket groove 41, an oil storage chamber is formed on the upper frame body 3, and the storage chamber The opening of the oil chamber is set toward the connecting groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com