Mine underground downward drift two-step stoping controlled blasting method

A technology for controlling blasting and mines, which is applied in blasting, ground mining, earthwork drilling and mining, etc. It can solve problems such as unreasonable design of the distance between the top hole, the auxiliary hole and the filling body, the difficulty in accurately controlling the blasting time of the blast hole, and the impact on the blasting effect. , to achieve the effect of improving the blasting effect of the section, good cutting effect, and accurate blasting interval time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] In this example, the surrounding rocks belong to grades II-III, with relatively good lithology, relatively difficult to blast, and a slightly arched section of 4×4m.

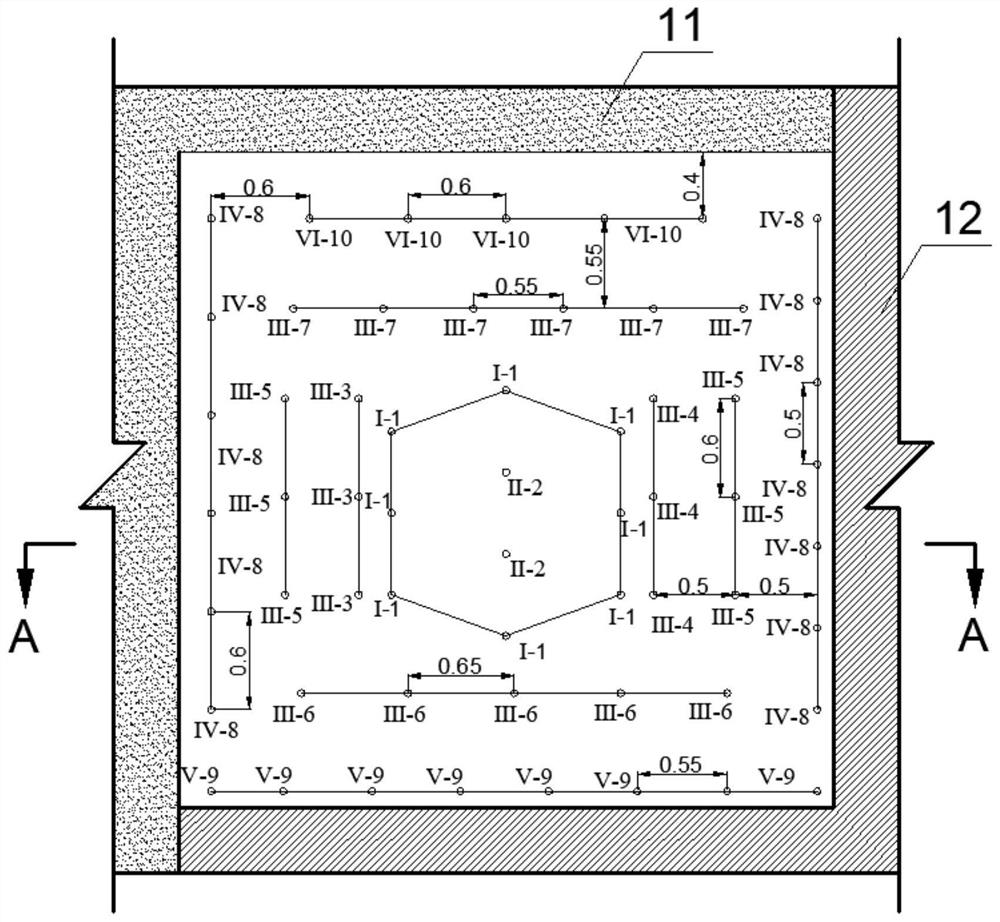

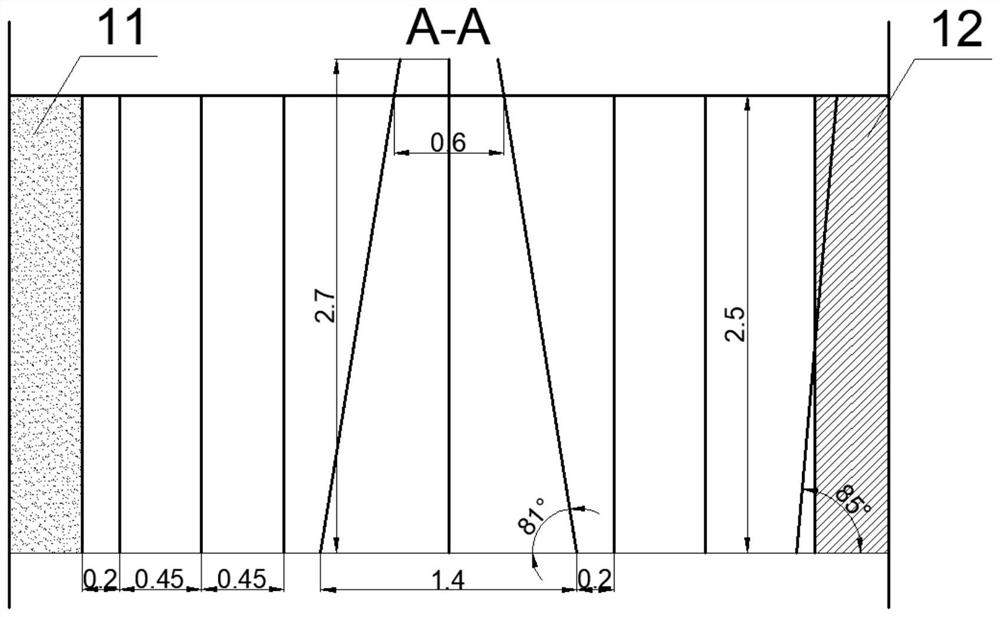

[0044] As a specific example, figure 2 Shown is the front view of the borehole design for the two-step recovery control blasting of the downhole approach. Among them, Ⅰ is the circular cutting hole, Ⅱ is the cutting hole, Ⅲ is the auxiliary hole, Ⅳ is the side hole, Ⅴ is the bottom hole, and Ⅵ is the top hole; the numbers 1 to 10 are the exposure sequence of the blast hole; the number 11 is Filling body, number 12 is surrounding rock. Firstly, a rock drilling rig is used to drill a hollow hole in the center of the section, and then a ring-shaped hole is drilled based on this. The vertical hole spacing is 0.5m, and the horizontal hole spacing is 1.4m. The super-deep slot hole is 0.2m, and the depth of the super-deep blast hole is 2.7m. Then, it is 0.1m away from the surrounding rock, and the auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com