Liquid cooling busbar

A busbar and liquid-cooled technology, which is applied in the direction of using liquid cooling for modification, cooling/ventilation/heating transformation, root rod/rod/wire/strip conductor, etc., can solve the problem of poor heat dissipation, small contact area of cooling medium, and restricted and other issues to achieve the effect of ensuring cooling effect, good cooling effect and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

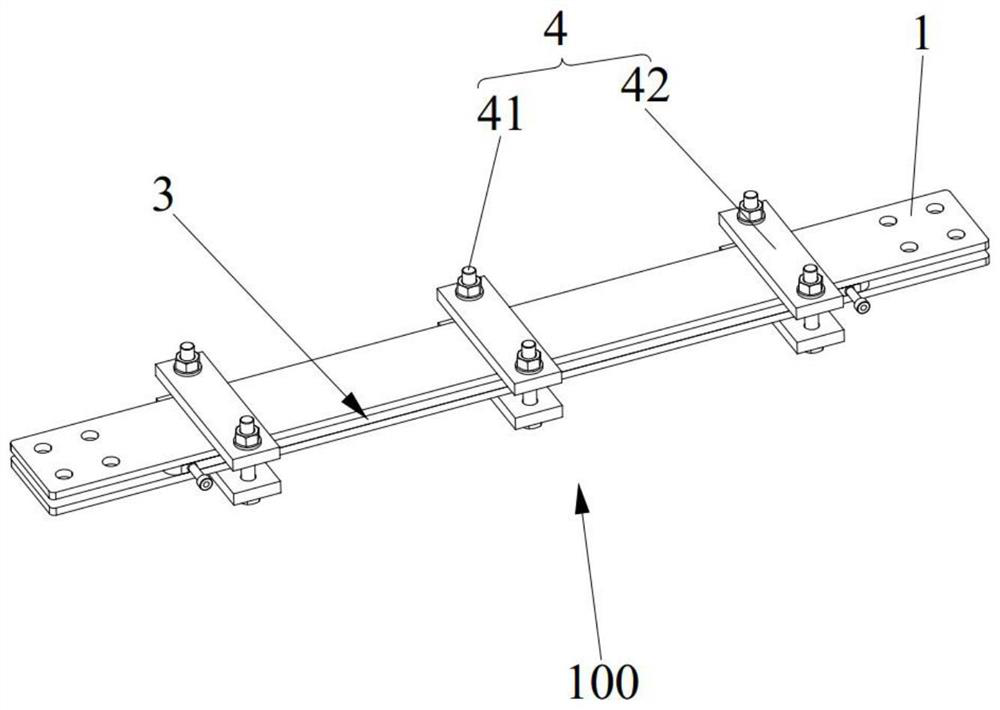

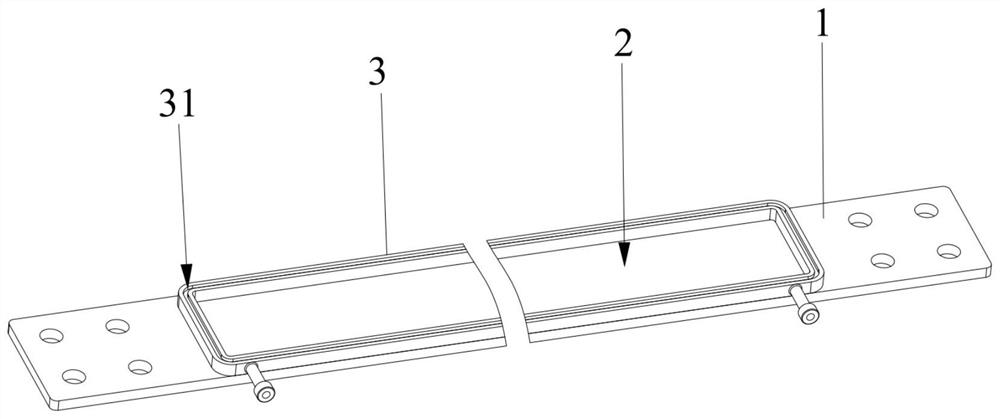

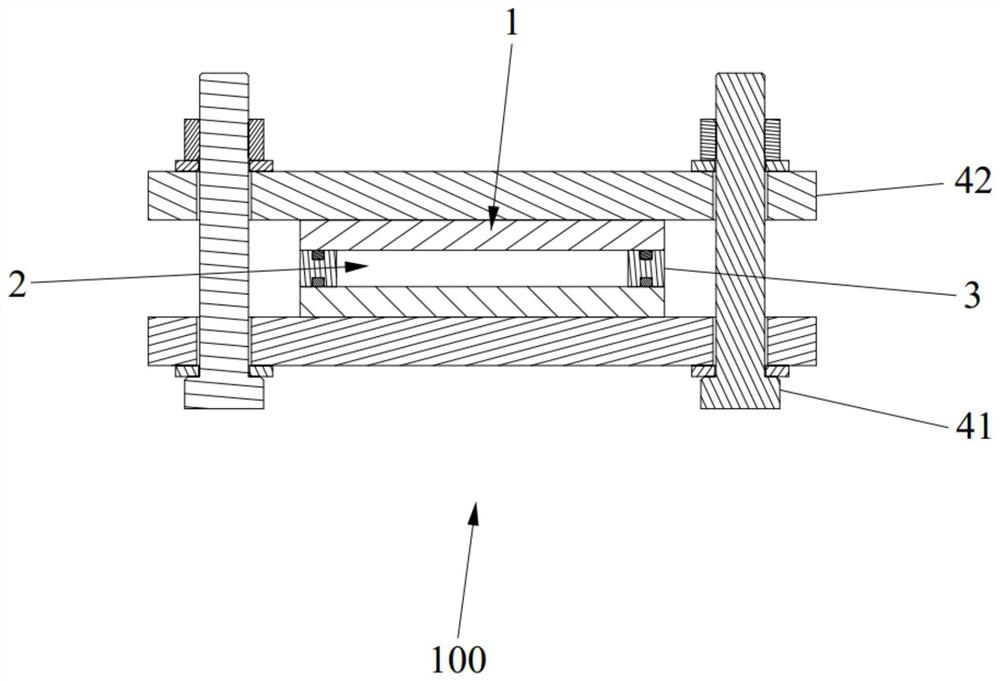

[0035] Such as Figure 1-Figure 4 As shown, this embodiment provides a liquid-cooled busbar 100, the liquid-cooled busbar 100 includes at least two busbar bodies 1, two adjacent busbar bodies 1 are arranged at intervals, and two adjacent busbar bodies 1 can A sealed cooling cavity 2 is formed, and a cooling medium is contained in the cooling cavity 2 . In the liquid-cooled busbar 100, the cooling cavity 2 is formed by two adjacent busbar bodies 1, the busbar body 1 can directly contact the cooling medium, and the direct contact area between the busbar body 1 and the cooling medium is large, and the cooling effect is good. Even if the distance between two adjacent busbar bodies 1 is small or the length of the busbar body 1 is long, the cooling effect of the busbar body 1 can be guaranteed, and the current carrying density of the busbar body 1 can be increased, thereby reducing the The cross-sectional area of the busbar body 1 reduces the manufacturing cost of the busbar body...

Embodiment 2

[0061] This embodiment provides a liquid-cooled busbar 100 , which is different from Embodiment 1 in that the number of sealing frames 3 between two adjacent busbar bodies 1 is at least two.

[0062] like Figure 5 and Figure 6 As shown, in some working conditions, the potentials of two adjacent busbar bodies 1 are the same, and the connection bar 200 of the equipment to be connected extends between the two adjacent busbar bodies 1, and is connected to the two adjacent busbar bodies 1 respectively. The main body 1 is electrically connected, so as to realize the electrical connection between the connection bar 200 and the liquid cooling bus bar 100 .

[0063] like Figure 7 As shown, in order to avoid the connection bar 200, the number of sealing frames 3 between two adjacent busbar bodies 1 is at least two, and each sealing frame 3 is surrounded by two adjacent busbar bodies 1. Assuming that a cooling cavity 2 is formed, at least two sealing frames 3 are arranged at interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com