Laser device chip positioning and clamping mechanism

A clamping mechanism and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of foveated folds, easy to be stressed and affected, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

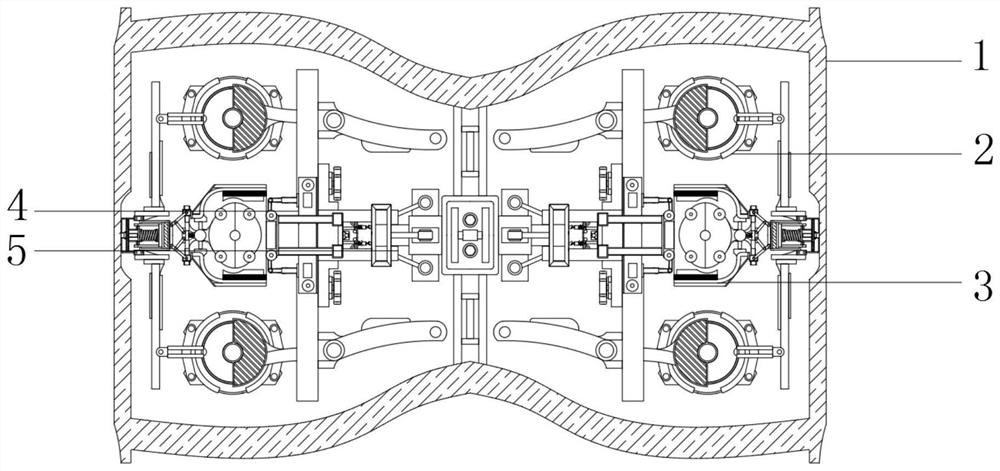

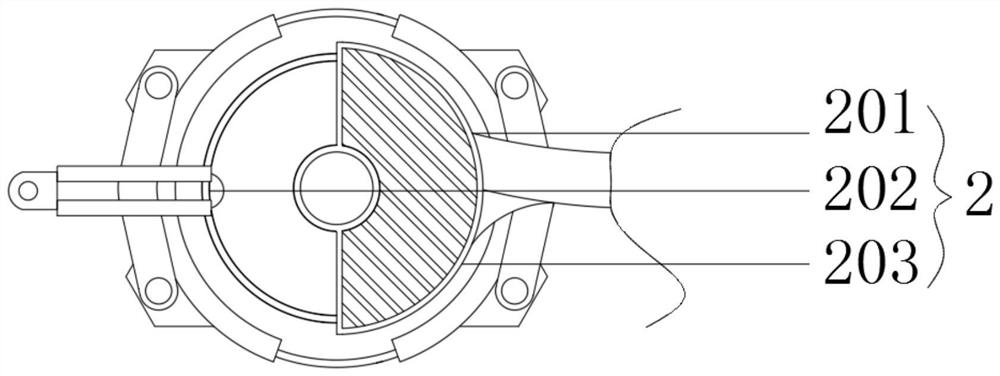

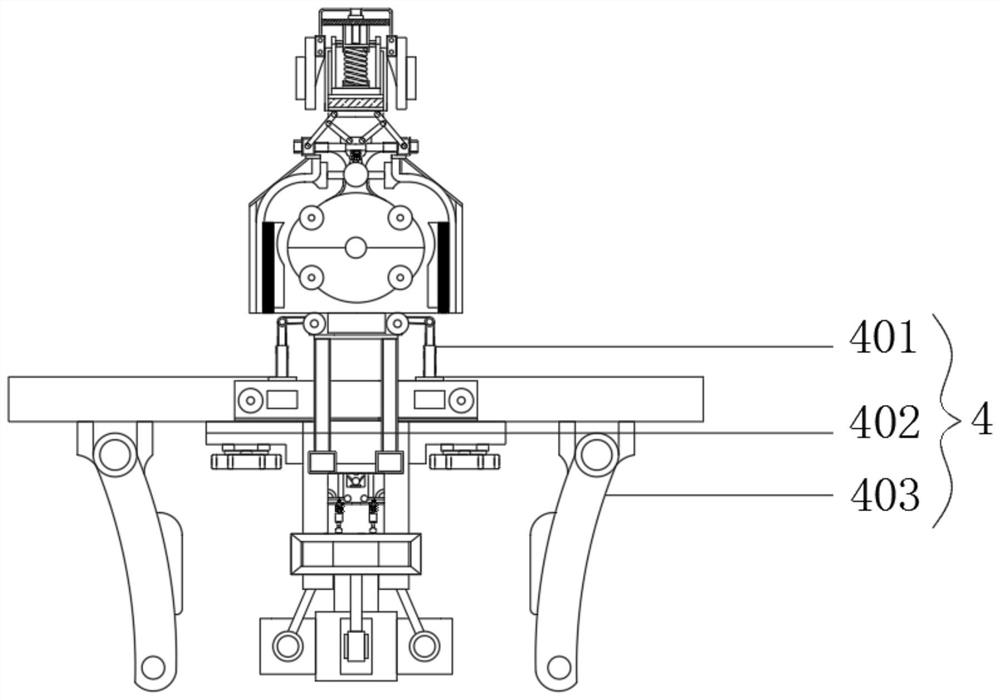

[0022] see Figure 1-5 , a laser chip positioning and clamping mechanism, including a chip positioning and clamping mechanism, the chip positioning and clamping mechanism includes a main clamping frame 5, the inner center of the main clamping frame 5 is movably connected with a fixed slide bar 504, the The left and right sides of the fixed slide bar 504 are movably connected with a curved clamping rod 403, and the outside of the curved clamping rod 403 is movably connected with a clamping rod frame 4, and the left and right sides of the clamping rod frame 4 Both are movably connected with a curved fit frame 304, and the outside of the curved fit frame 304 is movably connected with a stress buffer frame 3, and the upper and lower sides of the stress buffer frame 3 are movably connected with a connecting rod 201. The outer side of the bar 201 is movably connected with a distance-adjustable wheel frame 2 .

[0023] Further, the distance adjusting wheel frame 2 includes a connect...

Embodiment 2

[0027] see figure 1 and Figure 4 , a laser chip positioning and clamping mechanism, including a chip positioning and clamping mechanism, the chip positioning and clamping mechanism includes a main clamping frame 5, the inner center of the main clamping frame 5 is movably connected with a fixed slide bar 504, the The left and right sides of the fixed slide bar 504 are movably connected with a curved clamping rod 403, and the outside of the curved clamping rod 403 is movably connected with a clamping rod frame 4, and the left and right sides of the clamping rod frame 4 Both are movably connected with a curved fit frame 304, and the outside of the curved fit frame 304 is movably connected with a stress buffer frame 3, and the upper and lower sides of the stress buffer frame 3 are movably connected with a connecting rod 201. The outer side of the bar 201 is movably connected with a distance-adjustable wheel frame 2 .

[0028] Further, the main clamping frame 5 includes a lower ...

Embodiment 3

[0032] see figure 1 and Figure 5 , a laser chip positioning and clamping mechanism, including a chip positioning and clamping mechanism, the chip positioning and clamping mechanism includes a main clamping frame 5, the inner center of the main clamping frame 5 is movably connected with a fixed slide bar 504, the The left and right sides of the fixed slide bar 504 are movably connected with a curved clamping rod 403, and the outside of the curved clamping rod 403 is movably connected with a clamping rod frame 4, and the left and right sides of the clamping rod frame 4 Both are movably connected with a curved fit frame 304, and the outside of the curved fit frame 304 is movably connected with a stress buffer frame 3, and the upper and lower sides of the stress buffer frame 3 are movably connected with a connecting rod 201. The outer side of the bar 201 is movably connected with a distance-adjustable wheel frame 2 .

[0033] Further, the stress buffer frame 3 includes a torsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com