Motor rotor rotating shaft press-in device and operation method thereof

A motor rotor and shaft technology, which is applied in the field of motor rotor shaft pressing equipment, can solve the problems of poor rotor stability, small application range, and low automation level, and achieve the goals of improving stability, versatility, and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

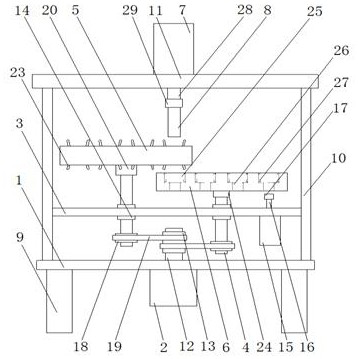

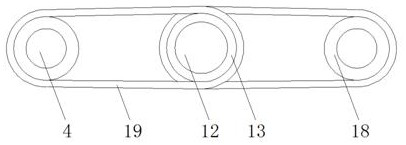

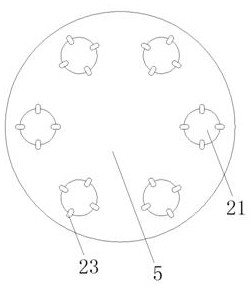

[0029] as attached Figure 1-5As shown, a motor rotor shaft press-in equipment, including a base 1, a motor 2, a fixed plate 3, a driven shaft 4, a bearing plate 5, a bearing plate 2 6, a hydraulic cylinder 7 and a pressure rod 8, is characterized in that : the base 1 is arranged on the support 9, a column 10 is vertically arranged on the base 1, and a top plate 11 is arranged on the top of the column 10, and the base 1 is connected with the support 9 and the column 10 by welding to strengthen the base 1 The connection strength with the bracket 9 and the column 10, and then improve the structural strength of the press-in equipment, the motor 2 is arranged on the base 1, and the motor 2 is provided with a transmission shaft 12, and the transmission shaft 12 is vertically connected from the top of the base 1 Stretch out, and be provided with driving wheel 13 on transmission shaft 12, described fixed plate 3 is arranged between column 10 and column 10, and is provided with bearin...

Embodiment 2

[0044] as attached Image 6 Shown: a motor rotor shaft press-in equipment, including a base 1, a motor 2, a fixed plate 3, a driven shaft 4, a bearing plate 5, a bearing plate 2 6, a hydraulic cylinder 7 and a pressure rod 8, which is characterized in that : the base 1 is arranged on the support 9, a column 10 is vertically arranged on the base 1, and a top plate 11 is arranged on the top of the column 10, and the base 1 is connected with the support 9 and the column 10 by welding to strengthen the base 1 The connection strength with the bracket 9 and the column 10, and then improve the structural strength of the press-in equipment, the motor 2 is arranged on the base 1, and the motor 2 is provided with a transmission shaft 12, and the transmission shaft 12 is vertically connected from the top of the base 1 Stretch out, and be provided with driving wheel 13 on transmission shaft 12, described fixed plate 3 is arranged between column 10 and column 10, and is provided with beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com