A power supply box externally connected with a self-triggering heat dissipation structure

A technology of heat dissipation structure and power supply box, applied in the direction of electrical components, power electronics modification, output power conversion device, etc., can solve the problems of limited heat dissipation effect, shortened service life, dusty power supply box, etc., to improve trigger accuracy , expand the cooling area, improve the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

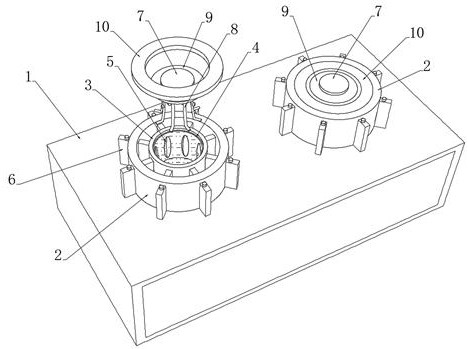

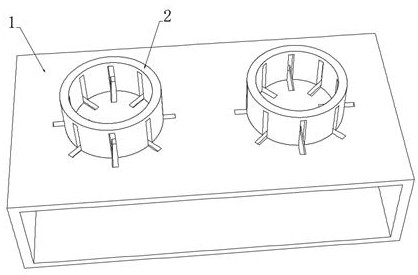

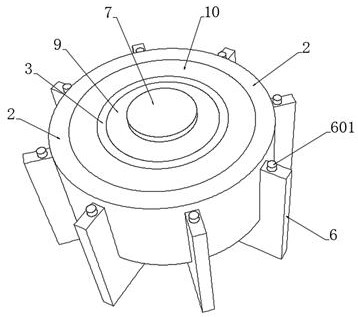

[0043] see Figure 1-3 , a power supply box externally connected with a self-triggering heat dissipation structure, including a power supply box body 1, a pair of water-cooled radiators are arranged on the power box body 1, and the water-cooled radiator includes water-cooled tubes 3 and radiating tubes 2 arranged inside and outside to dissipate heat The outer wall of the tube 2 is annularly embedded with a plurality of cooling plates 6 , and the outer wall of the cooling tube 2 is provided with an embedded cavity extending to the bottom thereof for installing the cooling plates 6 , and the inner ends of the plurality of cooling plates 6 extend to the outside of the water cooling tube 3 At the end wall, the lower ends of multiple cooling plates 6 extend to the inner side of the power box body 1, and the high temperature at the power box body 1 is transmitted outward by using the matching structure of the cooling tube 2, the water cooling tube 3 and the plurality of cooling plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com