Circuit board heat dissipation system

A heat dissipation system and circuit board technology, which is applied in the direction of electrical components, electrical equipment structural parts, cooling/ventilation/heating transformation, etc., can solve the problems of circuit board deformation, different heat generation, uneven temperature of the circuit board, etc. Uniform, speed up heat dissipation efficiency, avoid deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

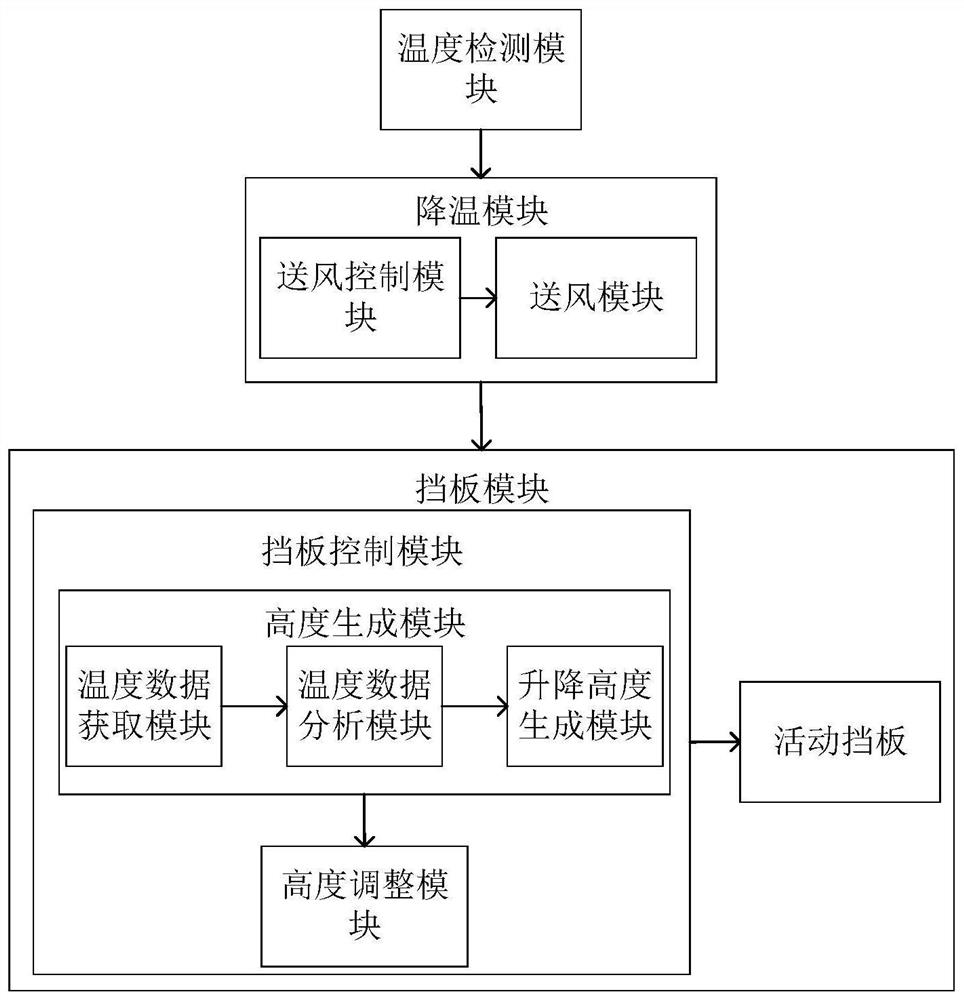

[0043] Embodiment 1 is basically as attached figure 1 And attached Figure 4 Shown:

[0044]A circuit board cooling system includes a temperature detection module, a cooling module and a baffle module. The temperature detection module is used to detect the temperature data of each area of the circuit board; the cooling module includes an air supply module and an air supply control module: the air supply module includes several air supply ducts 2 arranged laterally on the side of the circuit board, The air supply module in this embodiment is three air supply ducts 2 arranged laterally on the side of the circuit board; the air supply control module is used to control the opening and closing of the air supply duct 2; the baffle module includes a baffle control Module and several movable baffles 1: the movable baffle 1 is arranged above the circuit board and corresponds to each area of the circuit board. In this embodiment, the circuit board is divided into 6 regions, and 6 ...

Embodiment 2

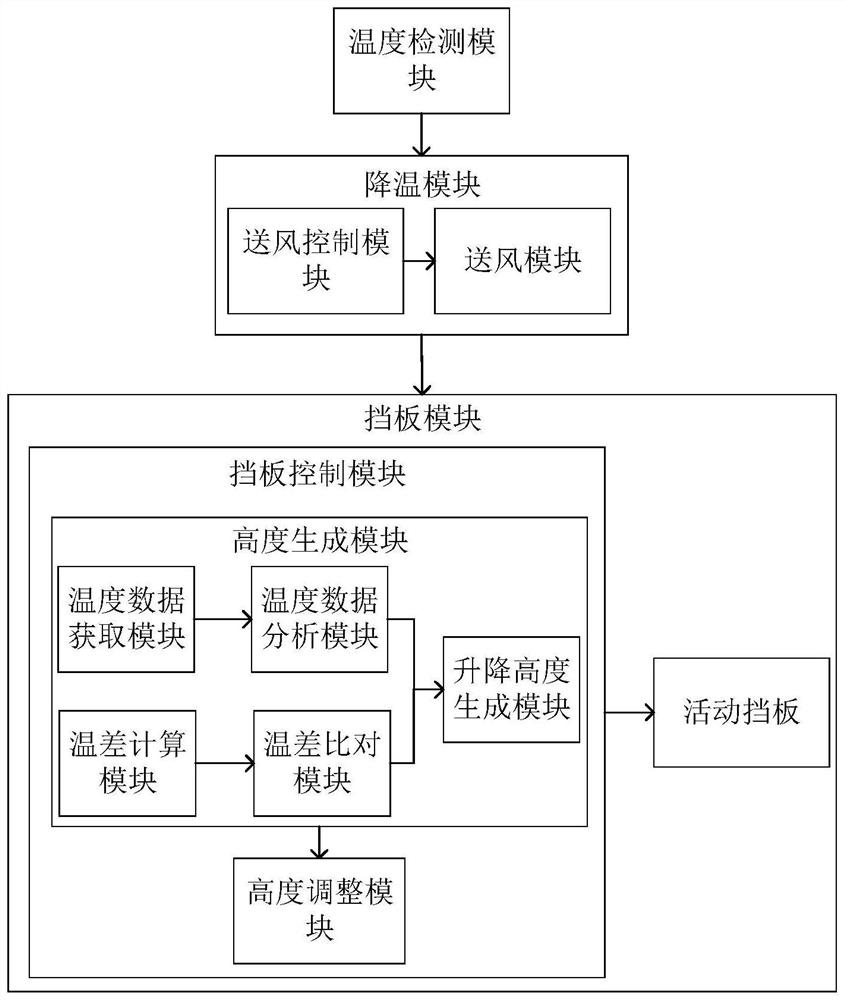

[0050] Embodiment 2 is basically as attached figure 2 Shown:

[0051] The basic principle of embodiment 2 is the same as that of embodiment 1, the difference being that the height generation module in embodiment 2 also includes a temperature difference calculation module and a temperature difference comparison module.

[0052] The temperature difference calculation module is used to calculate the temperature difference between each area of the circuit board and the area with the lowest temperature, and generate a calculation result;

[0053] The temperature difference comparison module is used to compare the calculation result with the temperature difference threshold and generate a comparison result;

[0054] The lifting height generation module is used to generate the lifting height of the movable baffle 1 corresponding to each area of the circuit board according to the analysis result of the temperature data analysis module and the comparison result of the temperature...

Embodiment 3

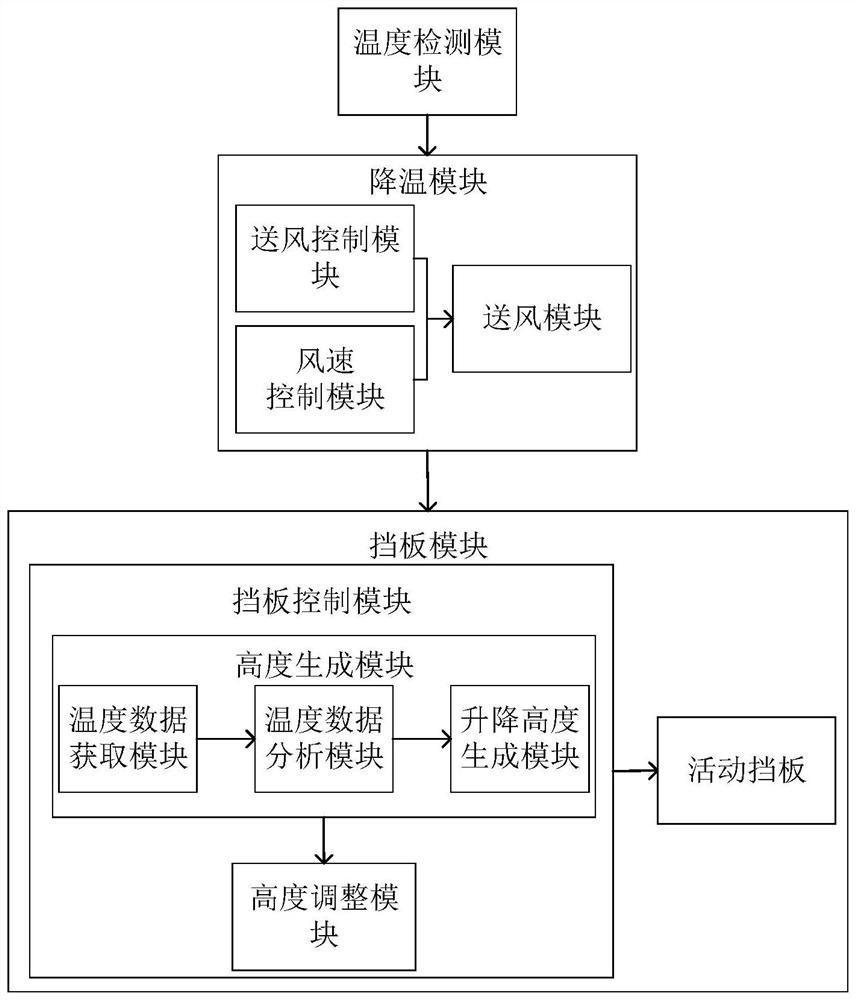

[0059] Embodiment 3 is basically as attached image 3 Shown:

[0060] The basic principle of embodiment 3 is the same as that of embodiment 1, and the difference is that the cooling module in embodiment 3 also includes a wind speed control module, which is used to control the air supply wind speed of the air supply duct 2 according to the temperature data of each area of the circuit board . In this embodiment, the initial air supply velocity of the air supply duct 2 is at the first gear, and when the number of areas whose temperature data is higher than the high temperature threshold exceeds one-half of the total area quantity, the air supply velocity of all the air supply ducts 2 will Adjust to the second gear. In other embodiments of the present application, when the temperature data in the area of the circuit board exceeds the high temperature threshold, the air supply direction can be adjusted to the air supply speed of the air supply duct 2 in the area. It is the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com